But what about media for the homemade 3D printer kits? If you’re into RepRap, Fab@Home or other kits, one of the first things you’ll realize is that there is no direct linkage to sales of print media. You have the freedom to experiment with practically anything.

Over time, the maker communities share the results of these experiments and the best products tend to rise to the top. One example of a third-party media supplier is Kraftmark, who make FabEpoxy, designed for use in Fab@Home printers.

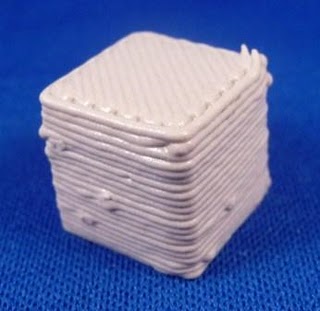

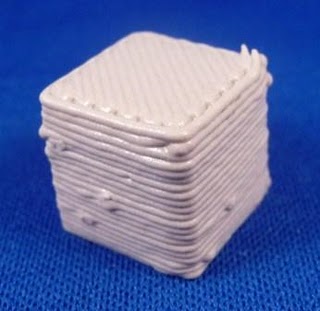

An example of the design characteristics: once you mix the two parts of the epoxy, you’re on the clock as it is gonna harden quickly. FabEpoxy doesn’t harden for 2-3 hours, permitting lots of time to load your Fab@Home deposition syringe with live FabEpoxy. Twenty-four hours later the printed object will cure into its final hardness.

Via Kraftmark, Fab@Home Wiki and KraftCreation

Thanks for the mention!