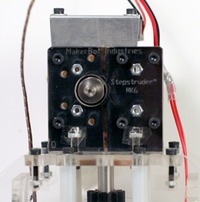

As long suspected and desired, MakerBot released a new extruder: The Stepstruder MK6. This has been sought after for some time by MakerBot fans as it should increase the quality of prints substantially.

As long suspected and desired, MakerBot released a new extruder: The Stepstruder MK6. This has been sought after for some time by MakerBot fans as it should increase the quality of prints substantially. How does it work? In simple terms, it permits extremely precise control over the extrusion flow. The MK6 uses a stepper motor instead of a regular DC motor to push filament into the hot end. A stepper motor differs from a DC motor in that it moves in precise “steps”. A DC motor, on the other hand, simply rotates when power is applied. The problem with DC motors is that when you cut power, the motor takes a few seconds to gradually stop spinning. While it’s spinning down it means there is still plastic being extruded. In practical terms, this means you have “stringies” and blobs. The MK6 should make those problems a thing of the past and reduce the motor-burn out problems that some have encountered. The MK6 requires using a new release of ReplicatorG, version 24.

Coincidentally, MakerBot simultaneously announced the availability of 1.75mm plastic filament to join their stock 3.0mm filament. The smaller filament size could make for higher-resolution prints when printed on the MK6, which includes the necessary parts for conversion. However, MakerBot is careful to indicate that 1.75mm printing is “experimental”. We’re watching for now.