It’s always a thrill to see an object emerge from a 3D printer. The object, previously visible only as an intangible digital model displayed poorly on a 2D screen is suddenly in your hand.

But imagine the thrill if that object being printed was intended to literally be part of you.

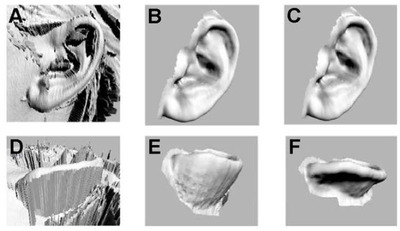

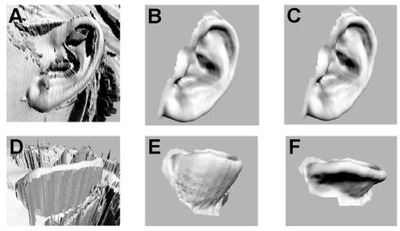

That’s precisely what happened at the Weill Cornell Medical College when scientists from Cornell applied their 3D printing knowledge to the case of microtia, a congenital deformity of the ear. Of course, this technique could also be applied to anyone missing an ear.

Apparently many thousands of children face microtia with little hope. Now it’s been proven possible that replacement ears can be produced using the new technique.

The process is not exclusively 3D printing, as it uses several other manufacturing techniques. After obtaining a digital model of the target ear (perhaps by scanning the “other” ear and reversing the model), an inverse of the model is used to 3D print a mold. The mold is then filled with collagen and cartilage cells, which, over several days grow over the collagen and form the ear structure. Then it’s simply a matter of implanting it into the patient.

We suspect procedures similar to this will gradually be developed for various body replacement parts as the technology is fully explored.

Via Kurzweil