If you’re making mechanical parts, you’d best use Simplify3D to slice them.

We’ve frequently written about Simplify3D because it is so useful. While some companies focus on building great hardware, Simplify3D focuses on 3D printer slicing software. And they do a great job.

The new release (2.2.2) includes a variety of general improvements, most notably a printing speed increase due to simplification of movements. While that’s obviously useful, the primary upgrade in this release is the ability to “achieve dimensionally accurate parts and customize the fit between meshing objects.”

Wait, what does this mean, exactly? Basically it ensures that parts intended to be printed closely don’t actually fuse together during printing. This is a very common problem for 3D models including moving parts. The new feature specifically is the “Horizontal size compensation”, which introduces a selectable amount of space between adjacent parts.

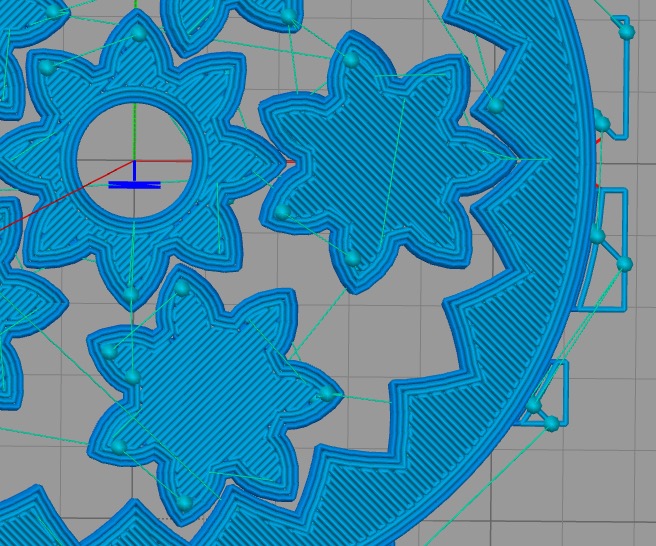

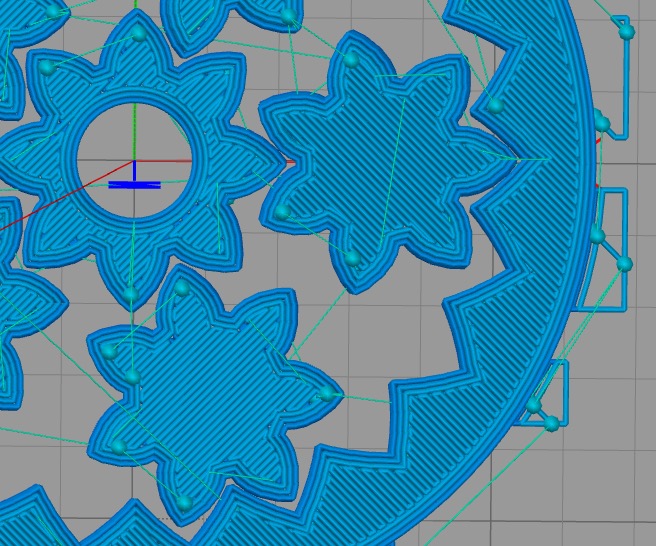

Here’s how it works. Check out the image at top; it’s a layer slice view of the famous Gear Bearing Skateboard Wheel by sphereinabox at Thingiverse. This item is a working wheel bearing – if it prints correctly. We’ve run this one off several times, only to be hugely disappointed when one or more portions are frozen together, rendering its rotatability limited. Or non-existent, actually.

Notice in the top image how some of the gear parts are very dangerously close to other parts. In practice, this usually means there’s a high risk of the parts fusing together during printing.

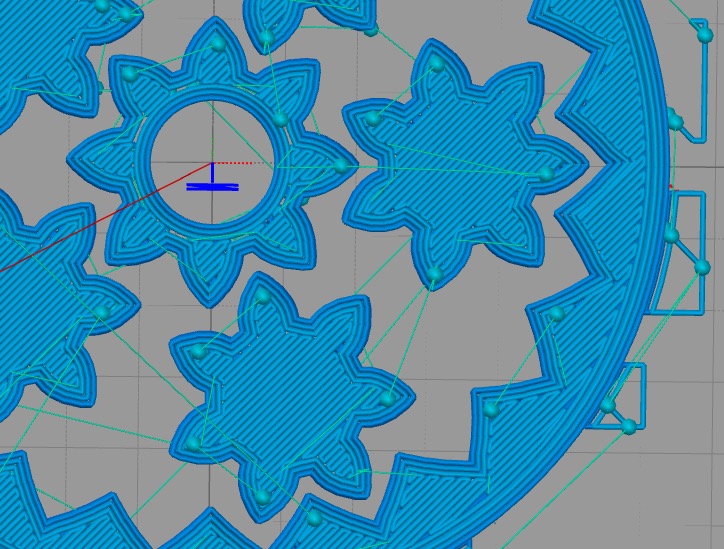

In the new Simplify3D, we specified a tolerance of -0.3mm, meaning it ensures a distance of 0.3mm between parts. As you can see here in this image, there is more than sufficient gap between the parts to ensure they’re mobile. Yes, we probably could close the gap a bit by specifying 0.2mm or less and it would work even better, but you get the point.

If you’re printing mechanical parts, this feature alone could be a lifesaver. But for everyone else, Simplify3D is also useful for so many other reasons.

Via Simplify3D