I’ve been doing some thinking about the “Industry 4.0” concept and believe it may drive the style of future 3D printers.

Up to now we have seen the development and marketing of various types of 3D printers using a wide variety of making processes. But all of them may be considered of the same style.

Let me explain by looking up the definition of Industry 4.0 from Wikipedia:

Industry 4.0 is the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things and cloud computing.

Industry 4.0 creates what has been called a “smart factory”. Within the modular structured smart factories, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralized decisions. Over the Internet of Things, cyber-physical systems communicate and cooperate with each other and with humans in real time, and via the Internet of Services, both internal and cross-organizational services are offered and used by participants of the value chain.

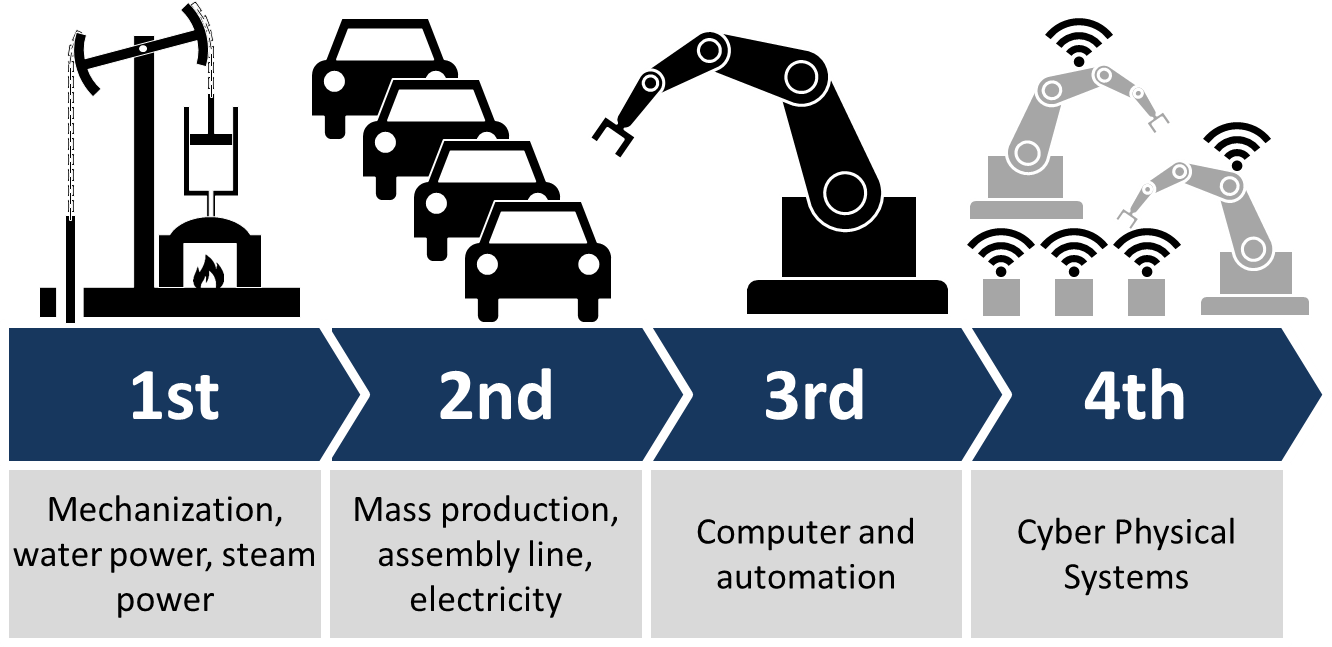

Another way to look at it is to examine this graphic (again courtesy of Wikipedia). As you can see, there is a progression of equipment and processes towards the “4.0” state, which is “wired” together – see those network icons on all the equipment?

Why do these machines want to “talk”? It’s all about coordination and efficiency. Think about the data that could be available from a machine as it progresses through its work, and imagine if that data was collected and analyzed. Or imagine if it was shared with the next machine in the manufacturing process.

Or imagine if the parts being worked on were automatically transferred to the next machine.

That is enabled by all this communication.

The sum of all that information can be analyzed and used to optimize, improve or even alter the entire manufacturing process. It’s kind of like having a much more flexible factory that can rapidly change what it’s doing in a coordinated manner.

That possibility suggests that future factories could produce new items faster and cheaper than ever before. And that’s a good thing.

But back to the style of 3D printers. Today’s machines don’t really talk much. If you’re lucky, a 3D printer might have an iPad app you can inspect to see what’s going on.

But that hardly qualifies as something you’d want to plug into one of these advanced “factories of the future” where all the machines are talking together to coordinate their larger mission of producing whatever it is they are set to make. In fact, most 3D printers of today require all kinds of manual intervention to operate them properly. Loading, unloading and maintenance is typically manual.

Dropping one of today’s 3D printers into such an arrangement would essentially defeat the purpose of Industry 4.0.

Thus I believe the following:

The style of 3D printers will split into two forms. One will be the 3D printers we see today: standalone devices used for one-off prototyping. The other will be a highly networked, instrumented and robotized device that is capable of rapid integration into a true factory of the future.

Are there any such 3D printers available today? I can’t say there is, although there seems to be some work in that direction.

Stratasys’ new concept machines are likely to involve many of these capabilities. Also some 3D metal and plastic printer manufacturers are starting to integrate robotic features that are reminiscent of this concept.

But there is obviously a long way to go before one will see true Industry 4.0 3D printers on the market.