BCN3D may have just set the standard for open source 3D printer companies with their latest release.

The company, a spin off of non-profit foundation, Fundació CIM, aspires to be the premiere opensource 3D printing solution to the industry. Specifically, they have just released significant design information regarding their Sigma professional desktop 3D printer.

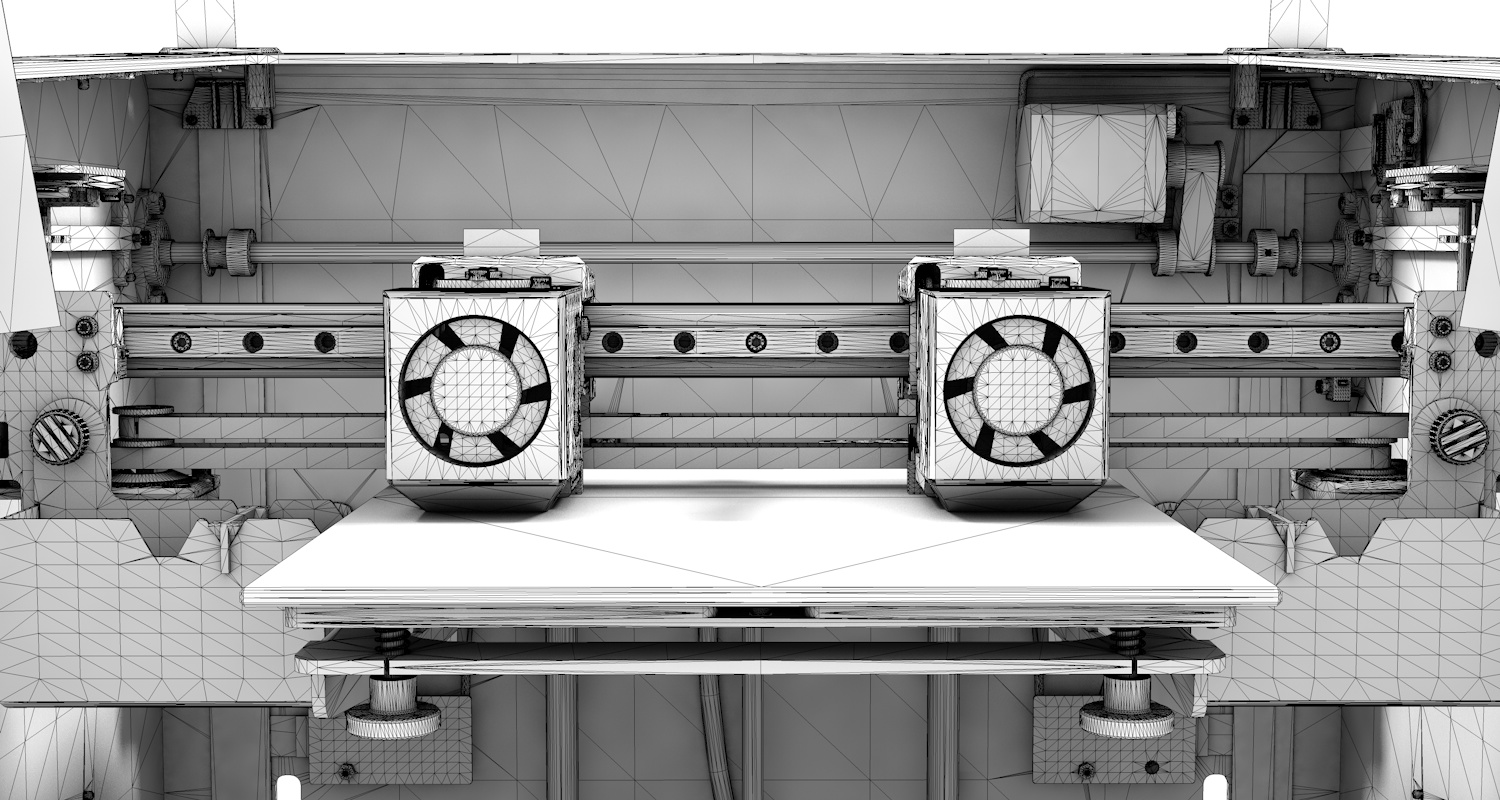

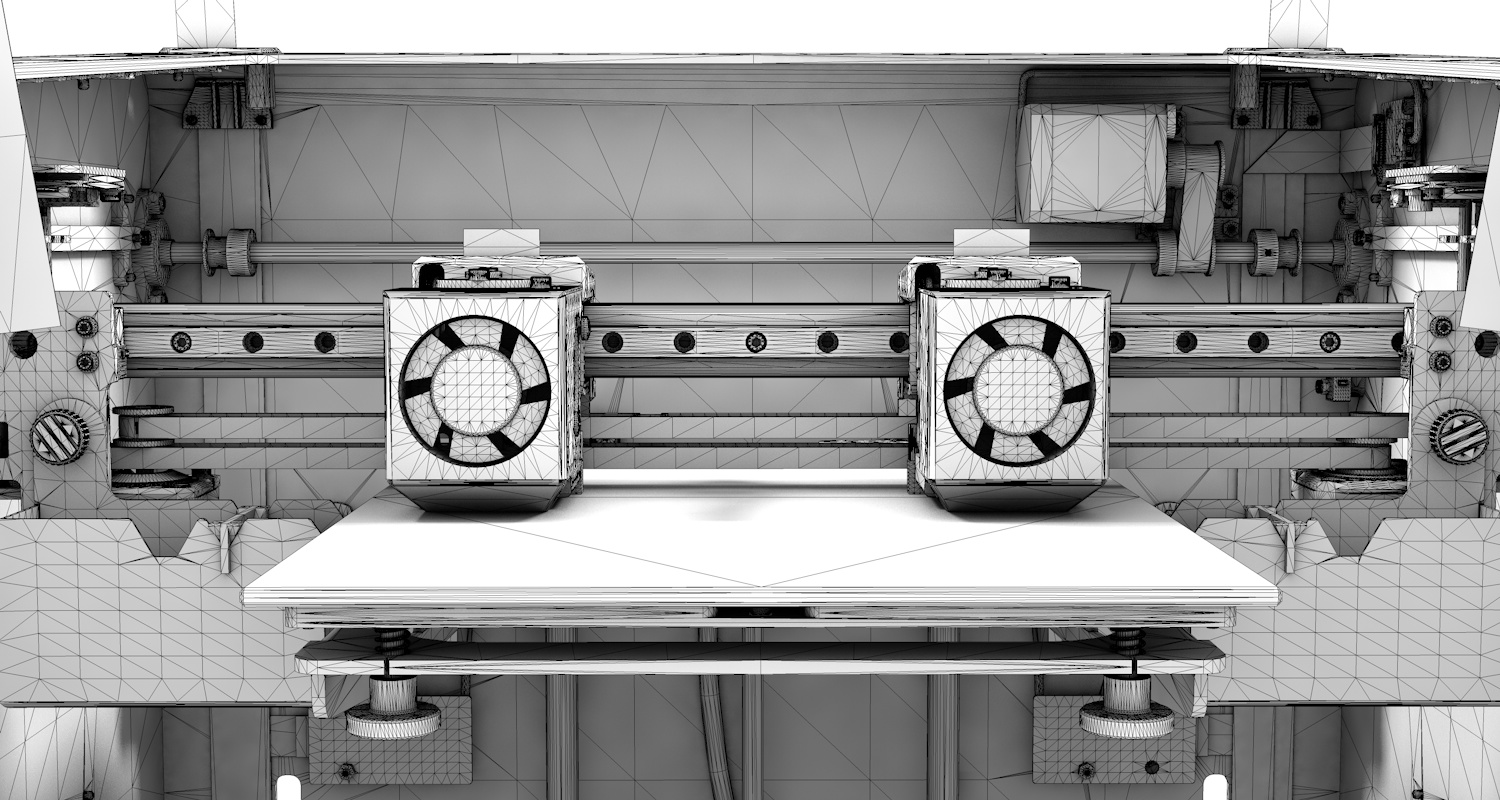

The Sigma is an interesting beast, having the unusual capability of independent dual extruders. Most dual extrusion machines have synchronized dual extruders, which are simply bolted beside each other. The Sigma’s dual extruders can move independently on one axis, creating the possibility for some very interesting printing optimizations.

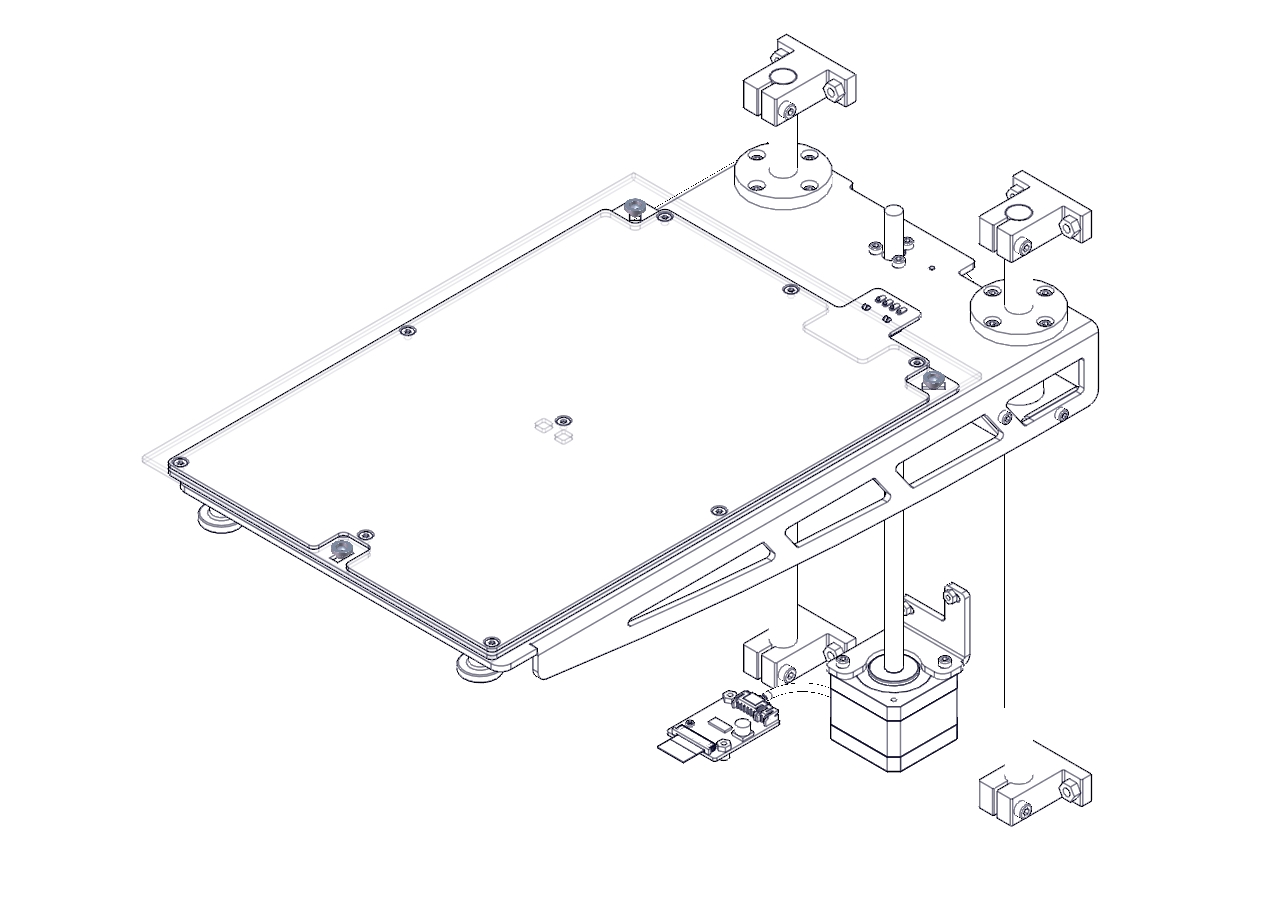

But back to the data release. Normally, one could claim to be open source if the design files are released, which typically means a pile of DXF drawings of the components and how they fit together. That could qualify you, as a company, as being able to claim the label, “opensource”. However, in practice, there’s a lot more to the story.

How, exactly, do you put those components together? What tools do you need? Are special jigs and fixtures required? What are their designs?

BCN3D’s latest announcement resolves all these matters by releasing, well, everything! Here’s what they say:

Regarding software, it will be published the BCN3D Sigma’s firmware –Marlin’s evolution- source code, as well as the BCN3D Cura. Also, the users will have access to all the mechanical design of the machine –so, its hardware-, including the 3D files and the assembling and 2D drawings.

On the other hand, regarding the process, the users will have access to all the assembling and QA files that are followed at the BCN3D production plant, based at Castelldefels, Barcelona. Same as the tools, equipment designs, and the testing bench used to adjust and calibrate the electro-mechanical components of the BCN3D Technologies 3D printers (tooling).

Finally, on the teaching level, all the contents of the courses given both in the BCN3D classrooms and its resellers all over the world will be included in the Open Source 360º.

Wow! That’s essentially everything you’d need to obtain components, assemble them efficiently, as well as train for and use the machine. Incredible!

Further, they add:

Taking this huge step, we want to show that a technological company can share its knowledge and keep leading its sector, generating contents for all the professionals, students or makers that want to know everything about the functioning and production process of their 3D printers.

I’m very impressed they would go to these lengths to open up their core data. With this release they surely join the few other opensource 3D printer companies, such as LulzBot and Ultimaker.

However, they also run a significant risk, one that MakerBot encountered some years ago.

In its initial incorporation, MakerBot attempted to be a similar opensource-style company, where the community would contribute to the designs and all things would improve. However, the company soon found offshore manufacturers were able to produce and deliver the “clone” equipment with the same design and sometimes similar components at far lower cost, undercutting MakerBot’s revenue.

MakerBot’s reaction was to close source on their printer projects, causing a significant rift in their community.

Could BCN3D fall to the same fate? Perhaps not, as the situation is somewhat different than it was in 2011, when there were far fewer open source designs on the loose. Today offshore manufacturers can find plenty of 3D printer designs available, often derived from those initial MakerBot plans.

I also don’t think that BCN3D has the same requirement for profit that MakerBot did in past years. MakerBot had taken on significant external investment from shareholders, presumably with the goal of making money. Thus, MakerBot was under pressure to deliver profit – and consequently shut down competition from clones. That’s not likely the case here with BCN3D.

As of now, however, BCN3D’s complete plans are definitely available for inspection by anyone, especially those interested in building a truly professional desktop 3D printer.

Via BCN3D