The WARR group from Germany has been 3D printing experimental solid rocket fuel.

WARR is a public student group operating at the Technische Universität München (TUM), currently working on a number of far-reaching and certainly ambitious projects, including Rocketry Satellites, Space Elevator, Hyperloop and even Interstellar Spaceflight.

While their main rocketry program centers around liquid fuel applications, it seems they’re also experimenting with solid fuel applications.

Solid rocket fuel has been around a long time and offers several advantages (simple design) and disadvantages (can’t turn it off once lit). Typically, the solid fuel is simply applied in a cylindrical pattern inside a tube. The fuel burns along the inner surface, thrusting out the bottom. The burn gradually consumes the cylindrical fuel structure until the walls of the rocket are encountered.

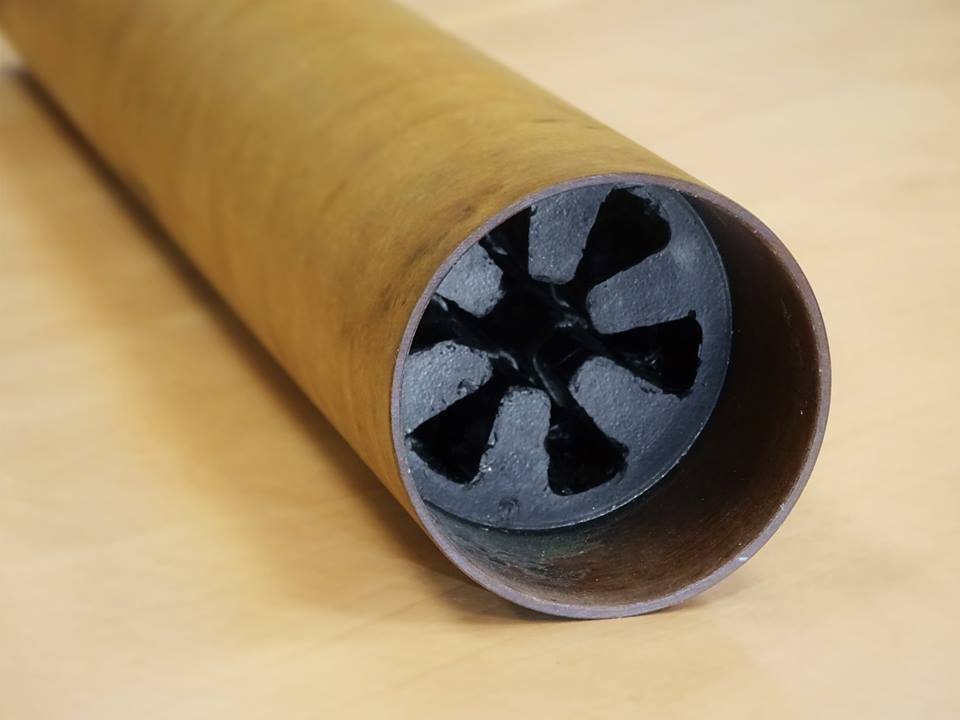

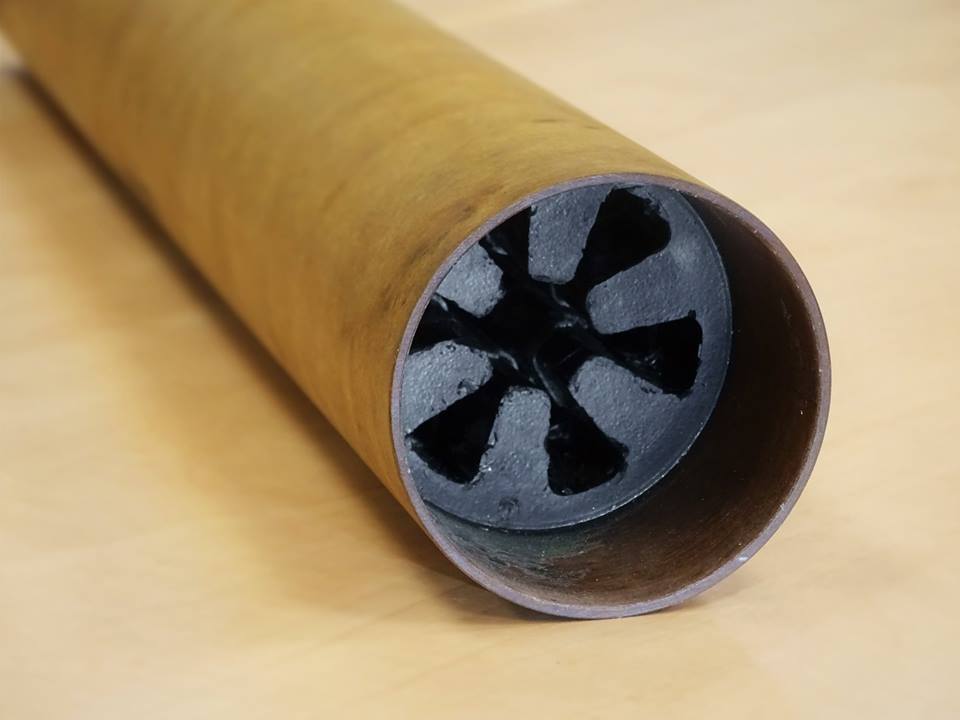

But here we see that the WARR team have been using 3D printing to develop alternative shapes for the solid fuel (image at top). This is quite interesting, as the shape of the fuel’s surface dictates the manner in which the burn executes.

By using alternative and varying shapes, the rocket can achieve different thrusts at different times during the burn. In this case I believe they are simply using a shape that offers more surface to burn than common cylindrical designs. This would mean a faster but shorter burn – providing more thrust. They say:

Using the first 3D-printed solid fuel grain, the engine’s thrust will be increased by over 200%.

But one can imagine a more complex design that perhaps provides higher thrust at the beginning and then slows down as the fuel is consumed. This could provide a more even thrust on the payload throughout the journey.

The WARR team explains how they used 3D printing in this experiment:

We 3D-printed a hollow plastic mold, sealed it, and cast the fuel around it. The cool thing is, the mold itself acts as fuel, too.

Yet another intriguing example of how 3D printing technology can make existing processes a lot better.

Via Facebook and WARR (German)