Markforged’s previous 3D printing equipment focused on high-strength materials like nylon, kevlar and carbon fiber, but now they’re into metal, too.

The new Metal X device uses a filament process: metal powder is mixed with a mystery material in rods, which is 3D printed in a manner similar to conventional 3D printing with filament. I presume rods are used because of the metal content: it’s almost as strong as the prints and wouldn’t easily be spooled as filament.

This produces a “green part” that must be sintered after printing. During sintering, the part shrinks some 20%.

This general type of process has been done elsewhere, but Markforged has an interesting twist in that the mystery material disappears during 3D printing, in their process called “Atomic Diffusion Additive Manufacturing”, or “ADAM”. The company says the completed parts will have 99% metal density, and post-print sintering is done to finish the required metal crystallization.

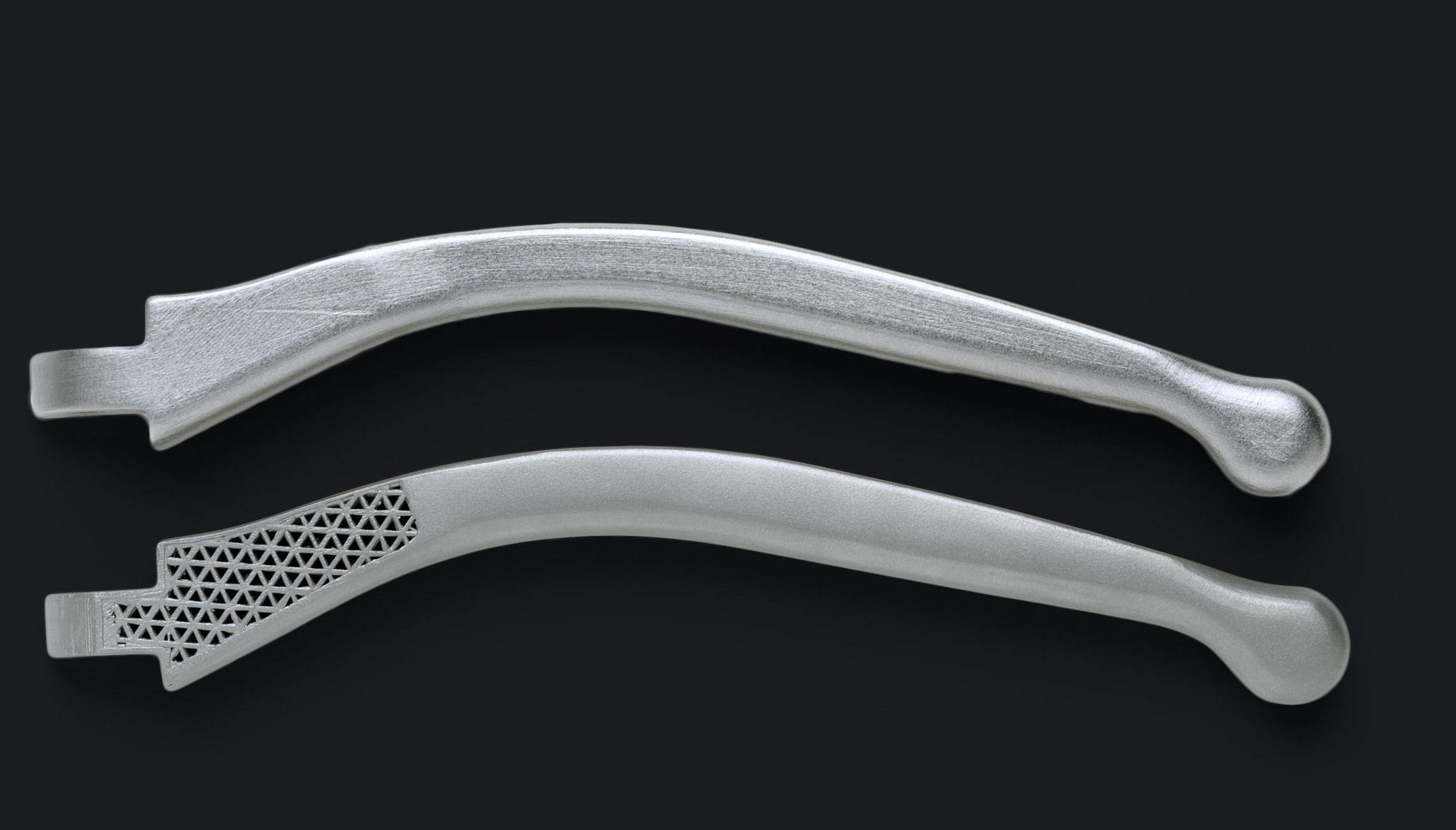

This enables them to do something the standard powder-based 3D metal printers cannot do: have truly hollow portions inside a 3D model. Those other machines would “trap” powder within enclosed shapes, adding to the weight of the part.

The ability to reduce weight is very important for some applications, such as aerospace and automotive, suggesting Markforged’s process will be welcomed by those industries. They can, with this machine, produce very lightweight parts with smooth exterior surfaces.

Currently the system can 3D print stainless steel and they are working on other materials such as aluminum and titanium. It’s likely this process could work with a wide variety of metals.

Build size is reasonable for smaller metal parts at 250 x 220 x 200mm, and layer thickness can be as small as 0.05mm, making fine prints possible.

The Metal X is now on sale at a cost of USD$99,500, but interest has been extremely high and they say there’s now a backlog up to 2017Q3.

Of note is the pricing of this machine: it’s drastically less than existing 3D metal printer options. Even more important is that the Metal X does not use powder, and thus all the complex, expensive and labor intensive powder handling equipment and processes are not required with this option.

The Metal X could be a very inexpensive and practical way to get started in 3D metal printing.

Via Markforged