I’m reading an article on Forbes describing a new process for 3D printing glass that could be quite useful.

Now, don’t get me wrong; glass 3D printing has been around a while. Typically it’s done using an extrusion approach, in which melty glass is extruded in a thick line to create simple 3D objects made from glass.

There are challenges with this approach, however. Since the thick molten glass can’t be extruded through fine nozzles, the resulting parts are rather coarse. The temperatures required for glass 3D printing are pretty horrific as well, with temperatures in excess of +1,000C required! That’s more than twice the maximum temperature of typical heat-based 3D printers today, and thus requires significant insulation and machine design.

One company is developing a professional molten glass 3D printer, Micron3DP, but they have yet to release the device. I am a bit skeptical about this approach, because the resolution is somewhat limited.

The other problem with molten glass 3D printing is that the results are not optically transparent. You get the shape, but you can’t see through it. Transparency is critical for many glass printing applications, particularly for lenses.

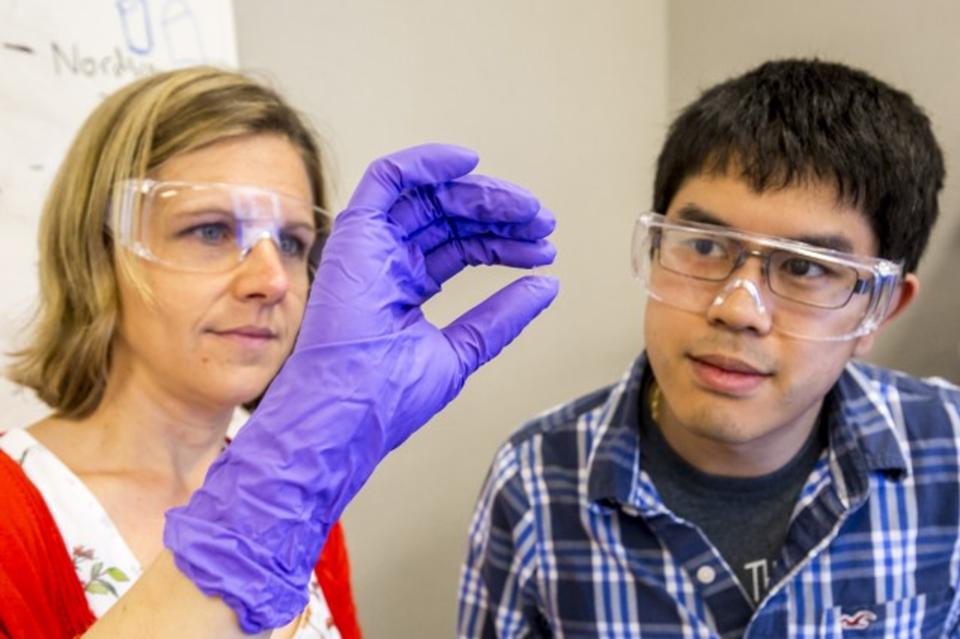

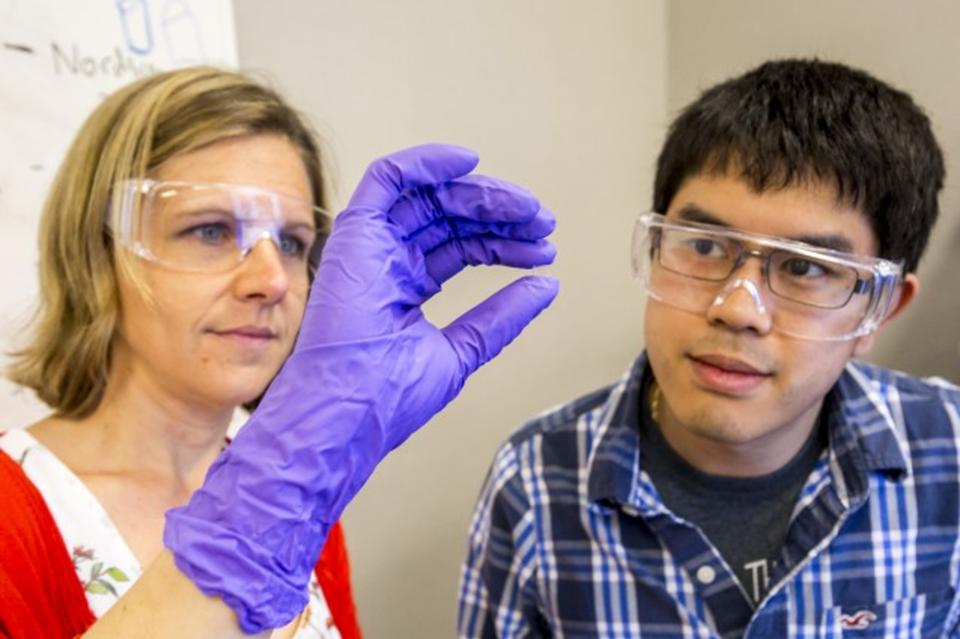

But just now there’s a new development from Lawrence Livermore National Labs, the folks who do work in these areas:

- Biosecurity

- Counterterrorism

- Defense

- Energy

- Intelligence

- Nonproliferation

- Science

- Weapons

Yes, they do nuclear stuff.

But many of these disciplines require fancy optical lenses, and apparently they’ve developed a new 3D printing process that can make them.

The LLNL approach involves the printing of a green part in a cold process. This is done with a liquid ink containing glass particles. Once the opaque “green” part is complete, it is then placed in a furnace to burn out the binder and fuse the glass particles together in the same shape as printed, more or less – and it become transparent. Evidently they are able to achieve “transparent, free form, and 3D with sub-millimeter features”.

Using this technique the LLNL researchers say they can produce optics equivalent to those created using conventional approaches.

That’s a huge development on its own, but there’s a lot more.

As the lens is 3D printed, the contents of the ink can be varied, just like materials can be changed on, say, an inkjet printer that changes colors. This means they can deposit different types of glass particles on layers and areas of the print.

And these different glass particles can have different indexes of refraction.

This means you could theoretically print a completely flat lens that operates properly because the index of refraction can change inside the lens! Apparently they can form all manner of unusual lenses using this approach. And the flat lens is vastly easier to polish than curved lenses.

I’m wondering if this invention will transform the glass 3D printing market in the same way that similar “cold” processes are changing the 3D metal printing market?

Via Forbes