This month’s community support selection is the Handsmith project by Lyman Connor.

Each month Fabbaloo selects a worthy non-profit project or activity contributing to 3D printing and provides not only a published story on the project, but also free advertising on our well-read pages. If your project would like to take part in the program, please fill out our application form here.

Connor works at GE engineering solutions for gas turbines, but in his spare moments there he’s been developing the Handsmith project. It’s a nonprofit initiative to equip folks with new, truly functional 3D printed hands.

Yes, you’ve probably seen something like this previously elsewhere. There are a number of other initiatives working on the same problem, which is the ridiculous expense incurred to purchase prosthetic hands made in traditional ways, sometimes exceeding USD$50,000 when you add up all the required purchases.

Several parties have developed rudimentary prosthetic hands and have obtained signficant press coverage. You can even download 3D models for hands from Thingiverse at no charge. But Connor’s Handsmith project is a bit different.

It actually works.

Connor used his significant engineering skills – and development process expertise obtained during his term at GE – to gradually develop a working model, starting with a single finger.

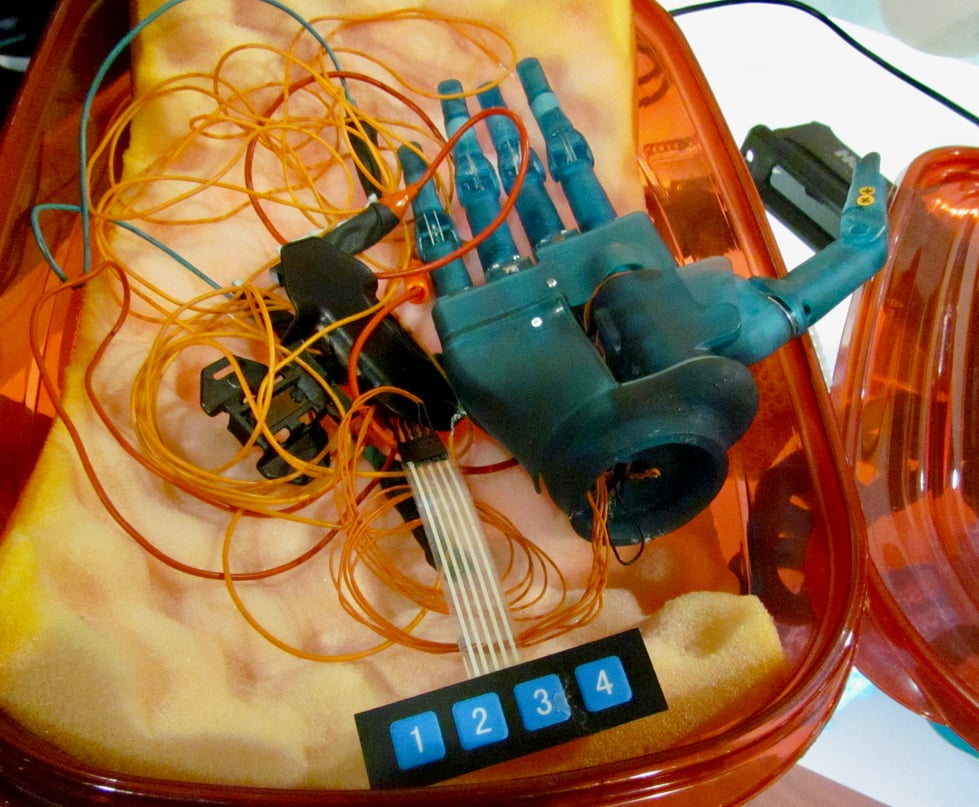

He began prototyping with basic plastic extrusion 3D printers, but found they could not produce suitable engineering prototypes. He was able to obtain such samples from expensive 3D print services that used industrial-level equipment, but that was simply too costly for the project. He instead turned to using Formlabs’ new Form 2 desktop 3D printer and was able to produce the parts in the required quality and also at the right price per unit.

In the development process, Connor obtained extensive feedback from actual users, something many other similar projects don’t do. Instead of simply assuming what the wearer requires, Connor asked them directly and found answers to be somewhat different than what you might expect. Users desired a very simple approach, operated by control buttons, for example. He added in some useful features, like embedded RFID keys, and opened the initiative in mid December as a spin off of his company, T3M.

Connor expects to begin shipping products for a March 2017 launch and anticipates producing around 30 hands per year at a cost of about USD$8,000 each. Pricey for some, but still far less than the cost of traditional products.

Of all the 3D printed hands available, the Handsmith could be the best available.

And if you know of another nonprofit / open source project that should can take advantage of our community support program, please fill out our form!

Via Handsmith