I’m looking at an extremely unusual 3D printer design: the Blackbelt.

The machine is designed by Blackbelt 3D BV of Venlo, Netherlands and is unlike anything I’ve seen previously. With one exception.

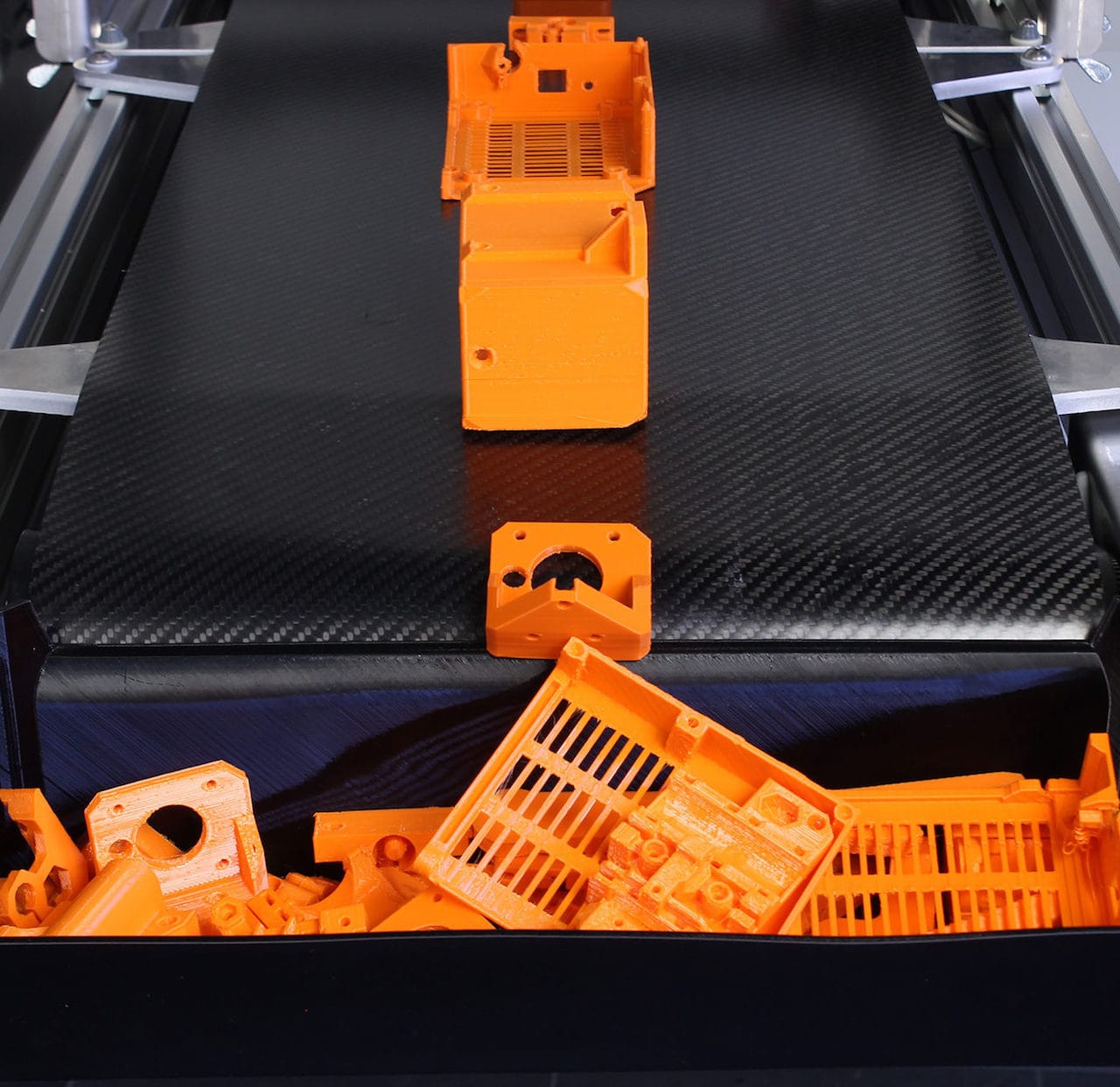

Years ago in 2010 MakerBot released something called the “Automated Build Platform”, a kind of conveyor belt system that fit overtop of your build plate. When the print finished, the belt would engage and slide off your print into a bin. I 3D printed tons of items automatically using this system.

Until it broke. The MakerBot ABP design was flawed in that the belt quickly work out, and prints no longer stuck correctly to the surface. In our lab, the ABP was deinstalled after a few uses. My understanding is that the ABP approach is patented by Stratasys and not available for others to experiment with.

But the idea of having a 3D printer automatically remove prints and continue printing is so compelling I have often written posts hoping for someone to duplicate this very attractive technology.

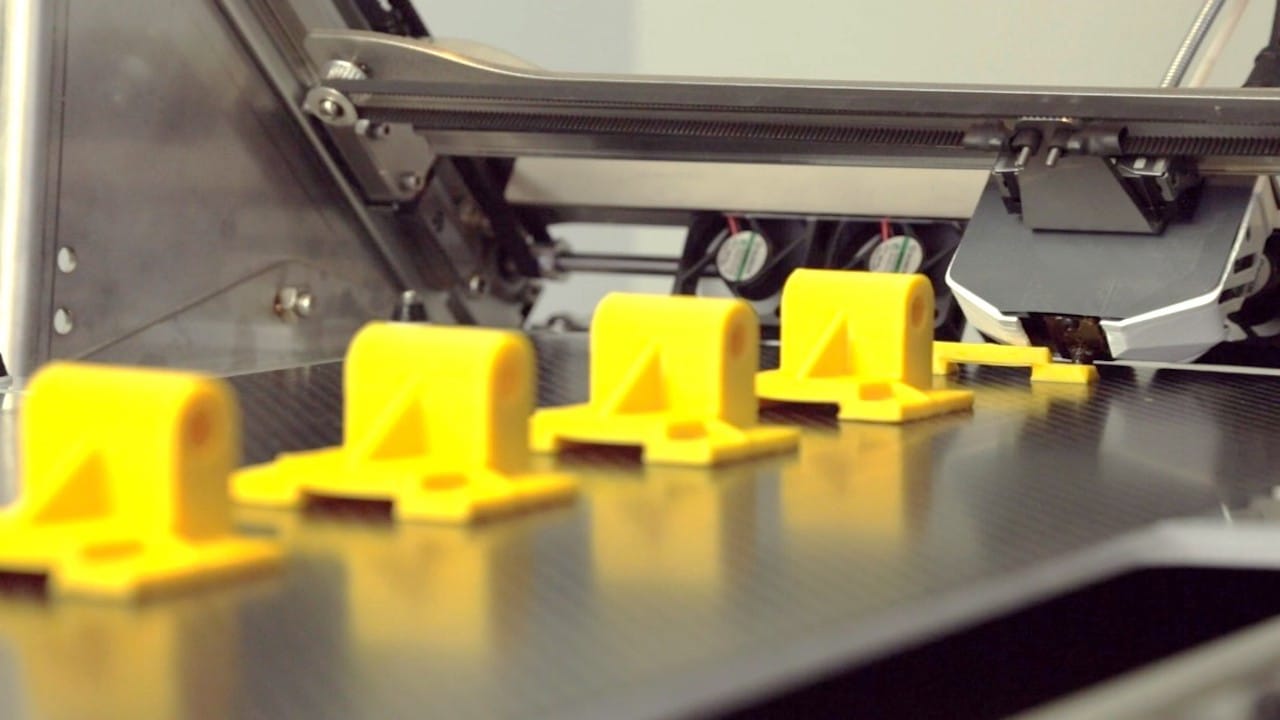

Now, that appears to be about to happen. Blackbelt uses a much more powerful conveyor belt system and a curiously angled extruder to enable continuous production, so long as you keep the plastic filament spool from emptying.

In the video you can see how this works. The build plate (or belt in this case) slowly moves while the extruder moves at an angle to deposit material.

As objects are printed, they move along the belt until it curls under, releasing the print and, once again, it falls into a bin. Theoretically such a machine could continuously print objects until the spool runs out, leaving you with a bin full of identical or different objects.

The angled extrusion approach provides a way to avoid using support structures on some geometries. However, there are still situations where you will require traditional support structures.

Blackbelt explains that the system can produce objects of 340 x 340mm, but the length can be quite longer. They say:

The Gantry allows building products of 340 x 340mm in x and y direction. For prints of 1300mm or longer, we recommend using the roller table to provide additional support while the printing process.

This automatically puts this device into the “large format 3D printer” category.

It seems to me that you could theoretically 3D print objects even longer by simply adding an additional roller table beyond the belt itself to receive an extra-long print. You’d be limited only by the size of your input filament spool.

I expect that this concept will become very popular, as the approach makes sense, is unique and appears to work. Evidently Blackbelt has patented their approach, so they will be able to market it at premium pricing to those requiring this functionality. And there are many possible applications, as shown on the company’s website. They 3D print furniture, profile extrusions, giant signs and many other things.

Can you buy this device? No, you cannot – it has not yet launched. The company says they will launch a Kickstarter campaign on June 1st, when we will see the full specifications for the device and of course, its pricing.

Via Blackbelt 3D