NASA announced they’re working on something called the “Refabricator”, and I’m wondering where this is going.

It appears to be the next logical step in their space-based manufacturing strategy, building on the already-operating orbital 3D printer by Made In Space, which concluded its initial tests in 2016.

The theory is that by having a 3D printer in orbit, you don’t need to ship up spare parts, as you could print them onboard, so long as you had sufficient raw material and the 3D design beamed up by radio.

This step has already been verified: Made In Space’s filament extrusion 3D printer was shipped up to the space station some time ago and was able to successfully 3D print a variety of objects. Since then, additional 3D printing gear has been installed and is working well.

But again, raw material is required. For these initial steps filament material was shipped up on cargo spacecraft, and each kg of shipment counts strongly. If you think the shipping costs for your spool of glow-in-the-dark 1.75mm filament were high, consider that the cost to ship that same spool to the space station would be around USD$2,700!

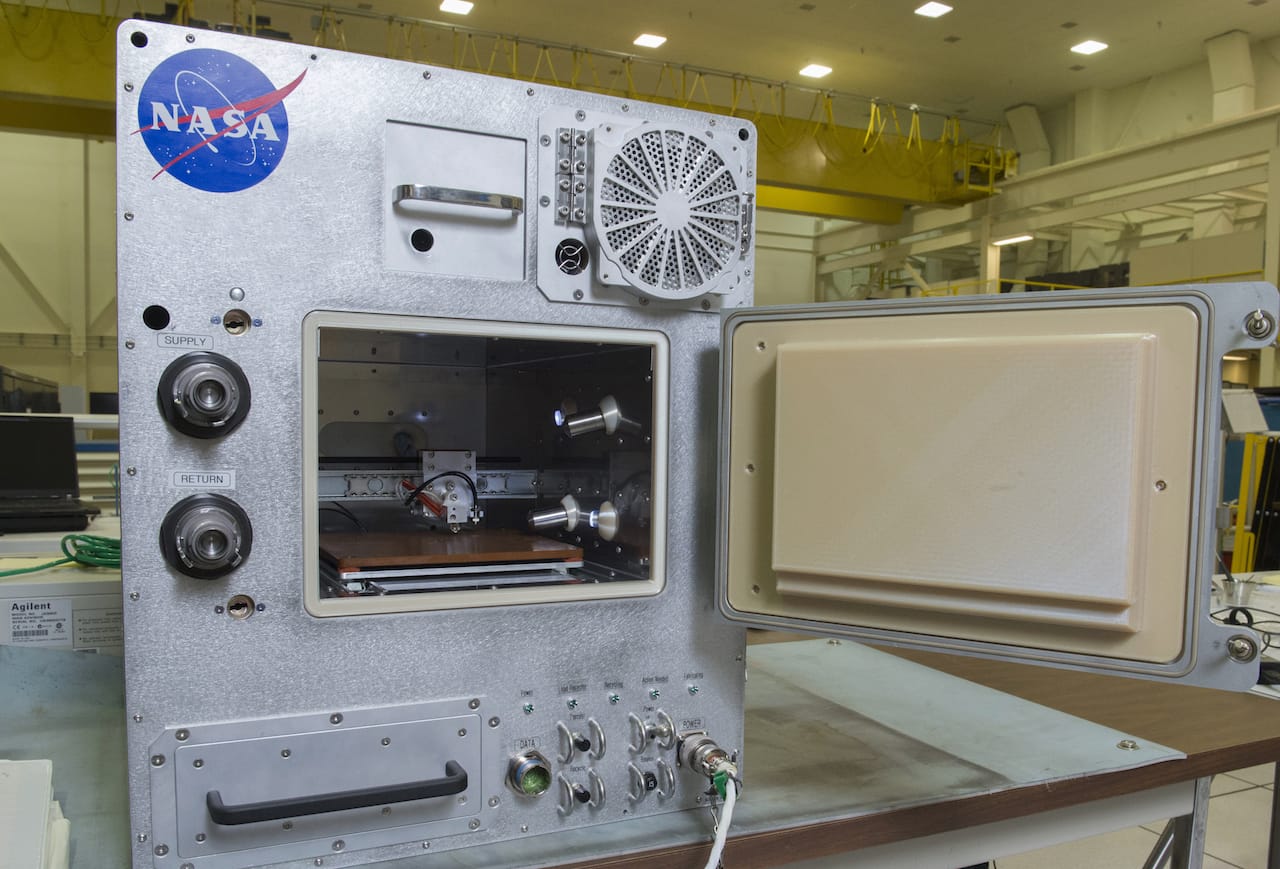

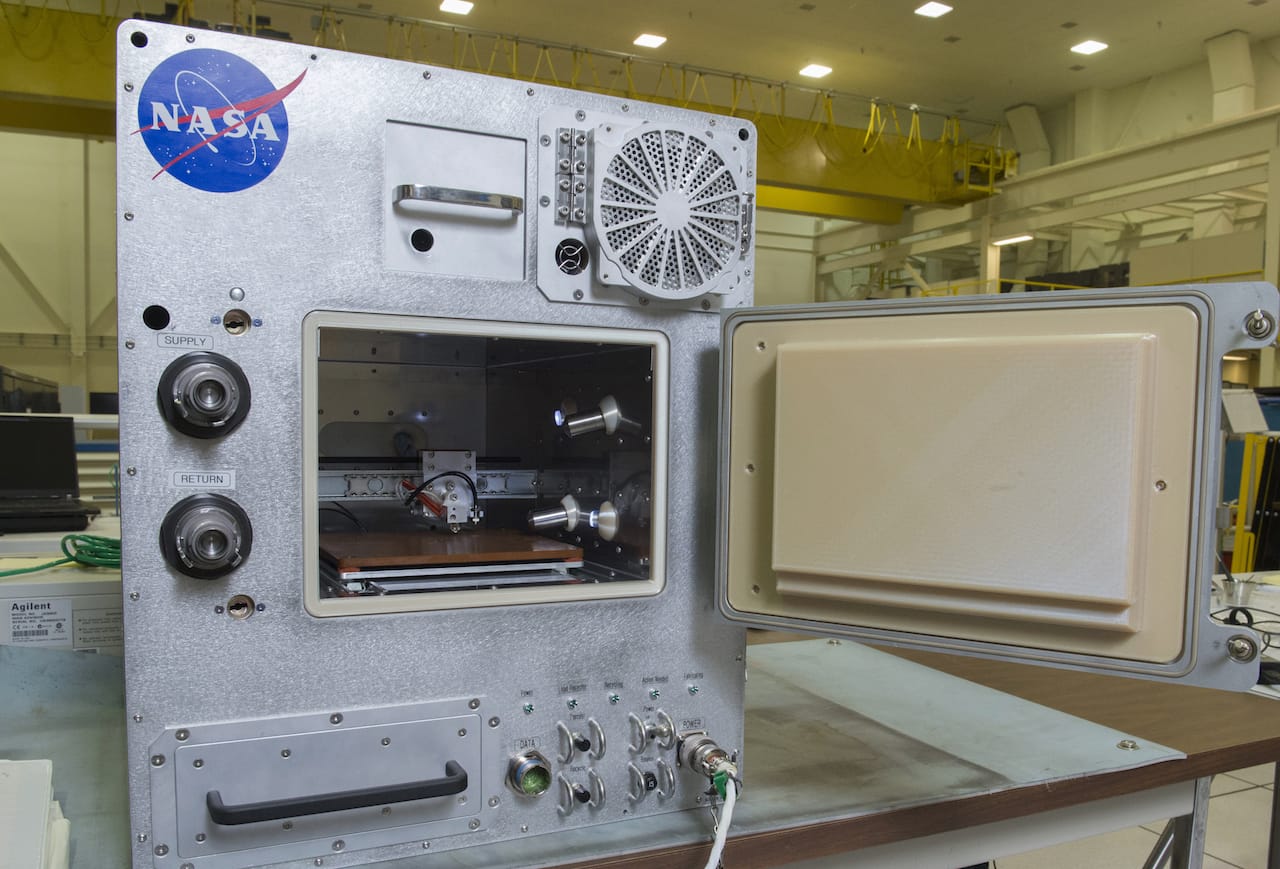

So it’s obviously a good idea to consider the possibility of recycling material, and that’s what the Refabricator project is all about. The prototype machine, to be built by Tethers Unlimited, is to be able to accept previously 3D printed items and restore the material to printable form.

If that sounds a lot like a small-scale filament recycler, you’d be correct.

While it sounds easy in concept, this is quite a difficult project. Even on the ground small scale filament recycling systems are notoriously difficult to get working properly. I cannot count the number of desktop “filament maker” projects I’ve seen come and go, and there seems to be only a couple that might be viable.

The challenge is to produce filament of appropriate quality to ensure flawless 3D prints. If the filament is of inconsistent diameter, for example, the resulting printed part could have slops or gaps, which may affect its functional performance. That could be a critical factor on the space station. Bad filament is worse that no filament, as it could even damage the 3D printer itself.

Even more challenging is that the Refabricator must be able to do all this in a weightless environment, in a completely air-sealed process, and operated remotely.

If Tethers Unlimited pulls this off, it will be a great thing.

For the space station, certainly, but more importantly it could be the foundation technology for ground based filament recycling systems as well. This could be a breakthrough for this technology that could change the market for 3D printer materials in some ways.

What if a prototyping workshop, that prints dozens of iterations each day, could recycle them all and effectively produce their own filament? What would happen to their previous supplier of filament, who expected to sell spools and spools each week to them?

What’s the next step? NASA explains:

The Refabricator will be the first integrated recycler-manufacturer in orbit and may eventually be able to recycle and print, using metal as well as plastic, with very little monitoring from the station crew members. By 2020, NASA wants to create a Fabrication Laboratory, or FabLab, to test an integrated, multi-material, on-demand system.

Recycling metal? That’s an even bigger step, but we’ll no doubt have to wait some years for this to occur.

Via NASA