It’s that time of year again, when the International Consumer Electronics Show (CES) engulfs Sin City like a human storm and attendees “ooh” and “ah” at the latest consumer technology.

For 3D printing, this used to mean a growing number of desktop 3D printers. Since the consumer 3D-printing hype bubble burst around 2014, things have changed.

Now that industrial 3D printing has demonstrated that, sometimes, you can actually believe the hype, CES may increasingly become an event where 3D printer manufacturers show off what you can actually do with the technology.

This was true last year when Markforged showed off the Metal X 3D printer, a comparatively low-cost metal 3D printer that could be used for fabricating molding to produce consumer goods. This year, Carbon is demonstrating what its ultra-fast Digital Light Synthesis (DLS) technology can do for consumer goods by announcing a partnership with Incase.

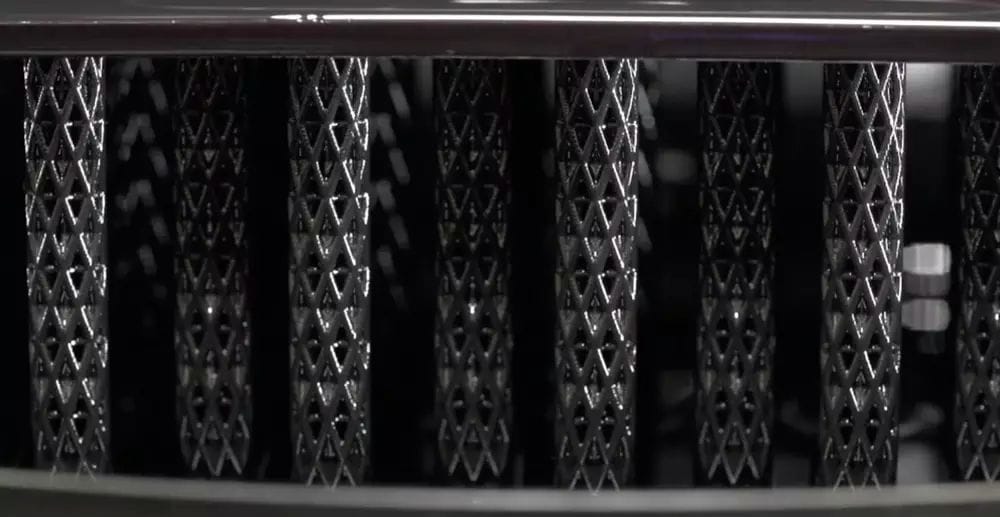

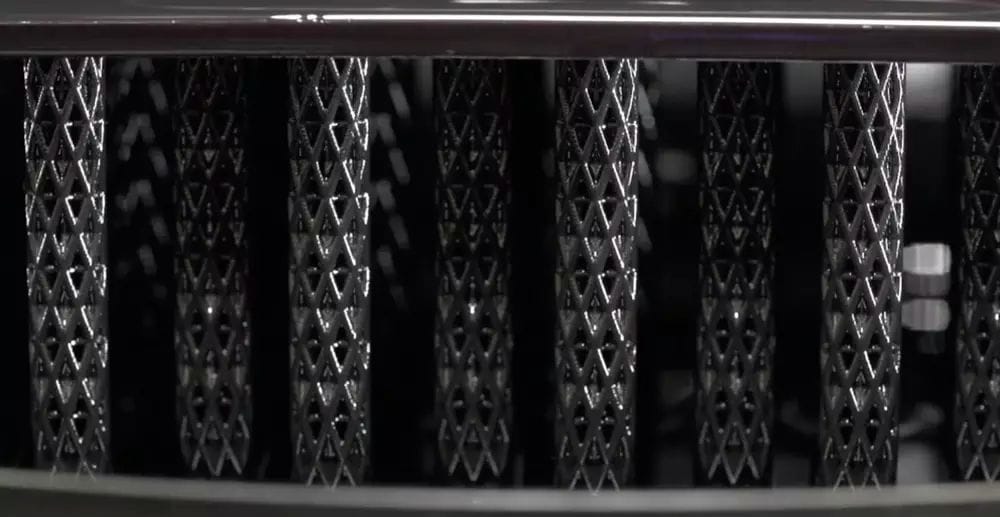

Look down at your phone or laptop and you may just see an Incase product protecting your device in squishy neoprene or rigid plastic. In case has joined Carbon for a multi-year partnership to use DLS—which creates layer less, engineering-grade parts, often in less than 10 minutes—to 3D print protective “mobile solutions” (read “smartphone cases”).

To do so, In case will have access to 20 M2 printers from Carbon. Incase also will leverage Carbon’s design and simulation software to drive the design process, as well as Carbon’s elastomers to create the products.

Read more at ENGINEERING.com