I’m reading material from Germany-based Multiphoton Optics and am staggered by the variety of applications.

Multiphoton Optics specializes in microscopic 3D printing. They employ an extremely precise optical system to solidify resin in shapes often too small to see with the human eye, printed with the LithoProf3D system.

You might wonder what kind of applications would need very tiny 3D prints, but it turns out there are many, far more than I would have imagined. And I suspect there are even more applications that have not yet been realized or discovered.

In the company’s latest release they’ve listed some of their recent accomplishments with clients and partners. Let’s take a look at some of them.

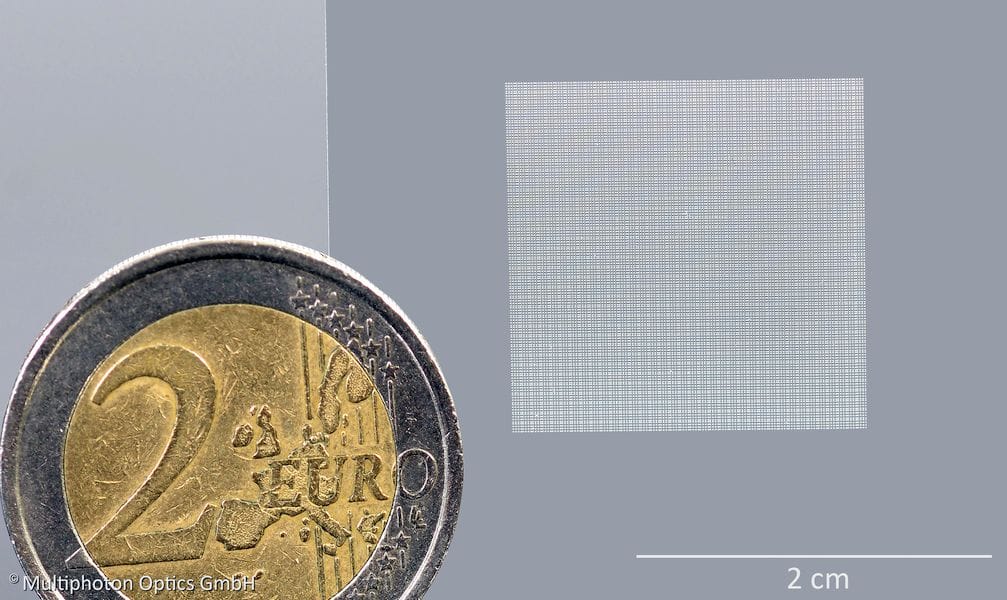

In the image at top, they’ve been able to print microscopic lens arrays. This 1cm square panel contains no less than 6,400 lenses so small you cannot see them. They’ve also been able to produce a 4cm square lens array containing 20,000 x 0.1mm lenses.

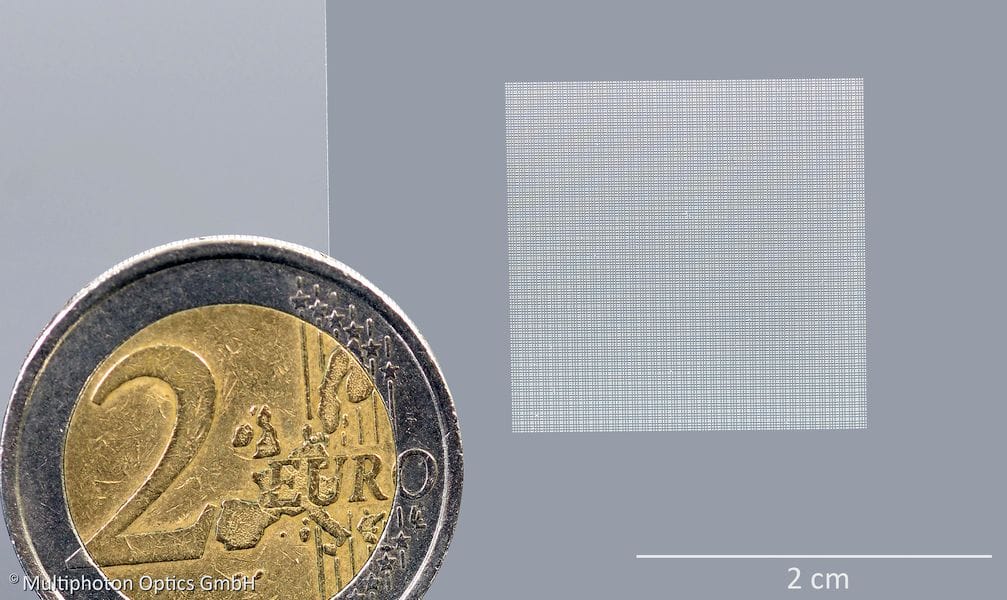

Another accomplishment was the ability to 3D print a precision lens directly on top of an LED. This development could be used in countless ways and could significantly simplify the design of many machines. Imagine ordering not just LEDs, but LEDs with a particular lens attached. That is now possible.

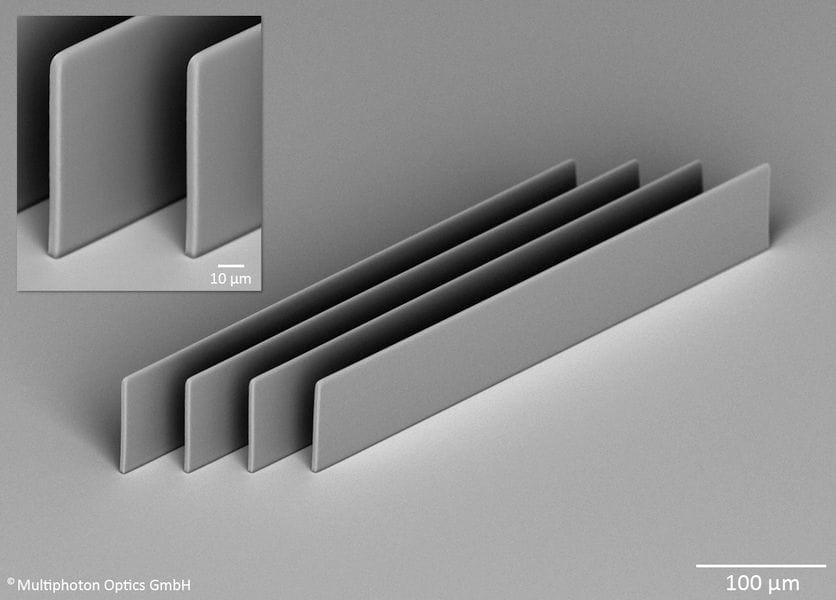

Here we see a series of microscopic structures. If you can’t tell their size, they are 0.5mm long, 0.08mm tall and only 0.005mm thick. For such a small object, it seems MultiPhoton Optics can produce relatively large item with such details.

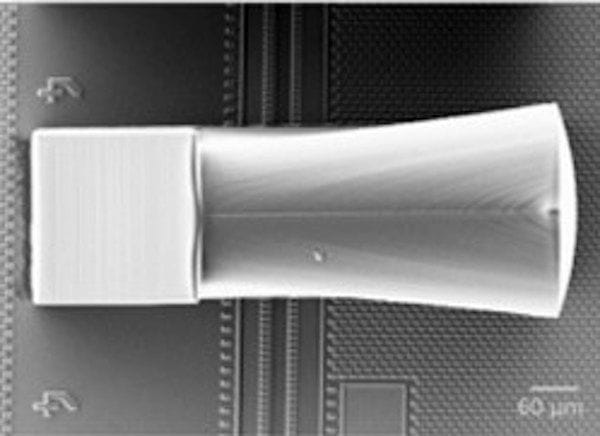

This is a microscopic grating coupler, 3D printed directly on a chip that permits coupling of optical interconnects. Multiphoton Optics says production o this part is almost 100x faster than traditional methods, as well as provided a vastly smaller solution – something always welcomed in electronic designs.

Companies such as Multiphoton Optics have been exploring this “tiny” market space for a few years and I suspect there will be a great deal more interest for several reasons:

- Efficiency of production of micro components

- The ever-increasing need for minuteqrization

- The ever-increasing need for lowering component weight

Please take a look at their page to see many more similar applications of micro-3D printing. I think we will see many more microscopic applications of 3D printing in the future.