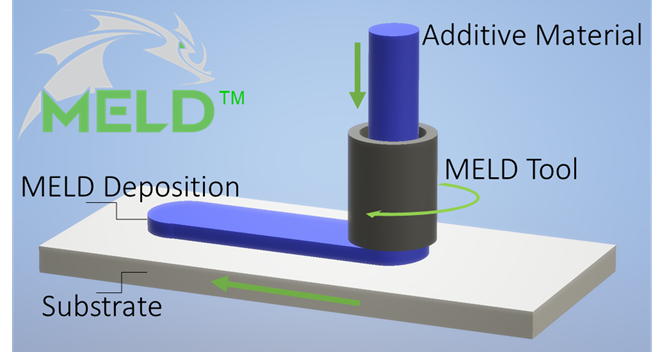

I’m looking at a new form of 3D printing made by MELD Manufacturing.

Their process, as you might guess, is called “MELD”, and it appears to be a friction-based technique for 3D printing of metals. Apparently previously known as “friction-stir” the process involves pressing a material against a target and rotating it rapidly. The friction softens the materials and cause them to fuse together.

Their video shows how it works:

There are several very important advantages to this approach over the more conventional powder-bed laser fusion process used by most 3D metal printer manufacturers.

First, the materials do not actually reach their melting points, thus the parts produced are not subject to the typical strength and lamination issues that are found in other 3D metal printing processes. The resulting parts are “solid”.

Second, because the material can be delivered to the tool head in solid form, there is no need for oxygen-free build chambers or special powder handling mechanisms. This alone makes this process far less expensive than anything involving metal powder, which can not only be toxic, but also explosive when airborne.

It’s also possible to use powder material – as long as it is properly handled – and thus you can mix different alloys together in the powder feedstock, as well as applying different materials by layer.

The MELD process can deposit material quite rapidly, but the cost of that speed is the resolution, which is actually quite poor, as you can see in the video and image at top. That said, it would be relatively straightforward to CNC mill the surfaces smooth after the print completes, assuming the geometry allows the CNC toolhead access.

Aside from 3D printing applications, this process can be used to apply new surfaces over old metal parts, as well as joining parts together effectively.

MELD Manufacturing says the process is good for 3D printing in a number of metals, including:

- Steel: HY 80, Stainless 316 L

- Aluminum: 1xxx, 2xxx, 5xxx, 6xxx, 7xxx series

- Magnesium: AZ31, WE43, E675, AMX602, E21

- Titanium: Ti64

- Nickel, Aluminum, Bronze

Like any 3D printing process, MELD has advantages and disadvantages. I suspect, however, that MELD is best suited for larger parts that require strength but not a great deal of surface detail.

And that is a lot of potential metal parts.