Holcim’s US$30B Spinout Leverages 3D Printing for Infrastructure Growth

Charles R. Goulding and Preeti Sulibhavi examine Holcim's strategic spinoff of its U.S. operations and pioneering efforts in 3D printing.

Growing IP Challenges in 3D Model Repositories Prompt Need for New Solutions

I’m seeing a growing issue with 3D model repositories that likely isn’t going to go away anytime soon.

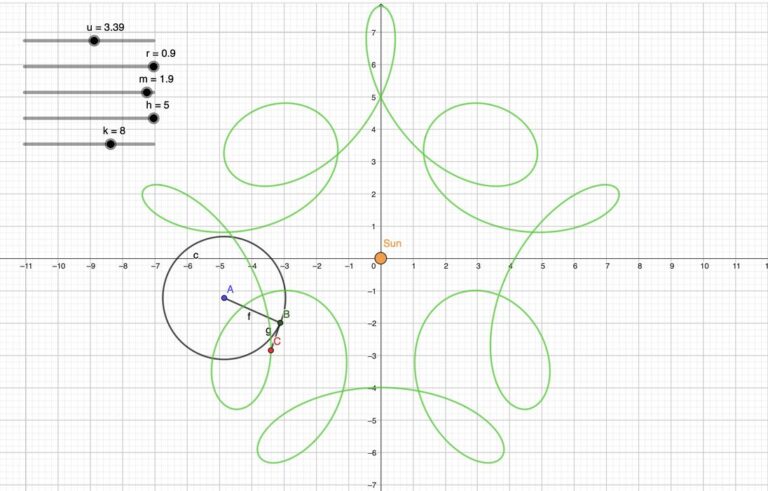

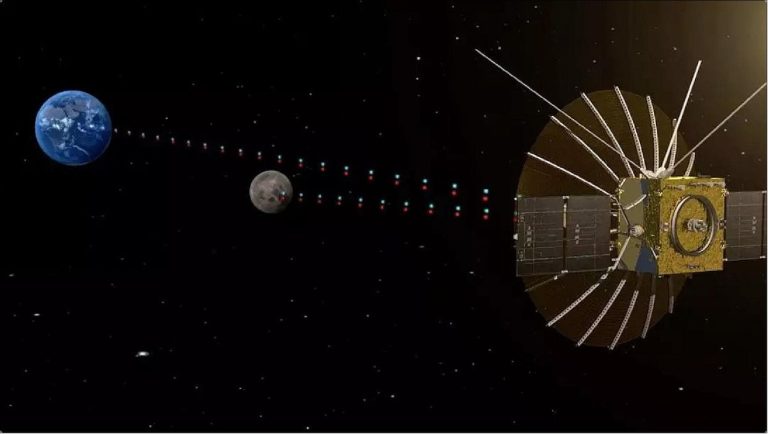

From Orbit to Object: Transforming Space Probe Paths into 3D Prints

A new research paper proposes a method to use interplanetary space probe trajectories as a method to generate unique 3D printable designs.

Renishaw to Boost 3D Printing Capabilities Through New Partnership with Materialise

Materialise announced a partnership with Renishaw that should benefit Renishaw 3D printer operators.

Hellen Obiri Won the Boston Marathon Wearing 3D Printed On Shoes

The Cloudboom Strike LS is a prototype running shoe that could soon become commercially available.

Skyward Revolution: 3D Printing Propels eVTOL Innovation

Charles R. Goulding and Preeti Sulibhavi discuss how companies such as Wisk Aero and Airbus are leveraging 3D printing technology to revolutionize urban air mobility.

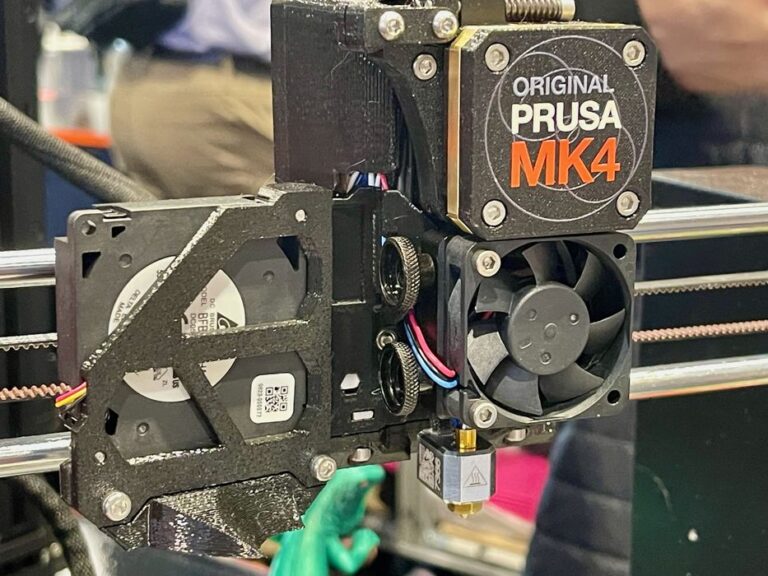

New Firmware 6.0.0 Introduces Advanced Features for Prusa’s Latest 3D Printers

Prusa Research has released a major update to its 3D printer firmware, version 6.0.0.

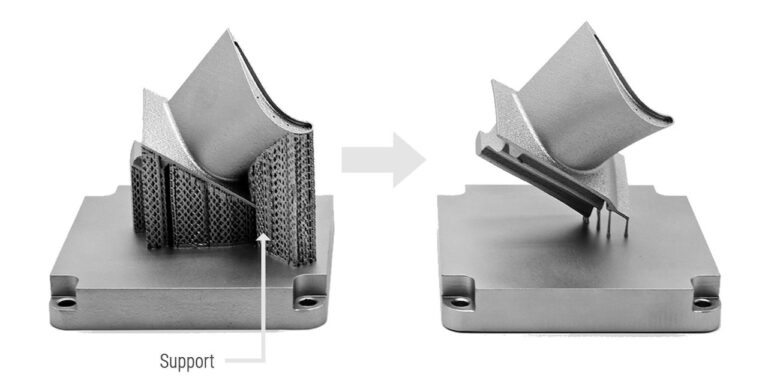

Farsoon’s New SRS Tech Reduces Metal 3D Printing Support Needs

Farsoon introduced an almost unreal method of printing support structures for metal 3D prints.

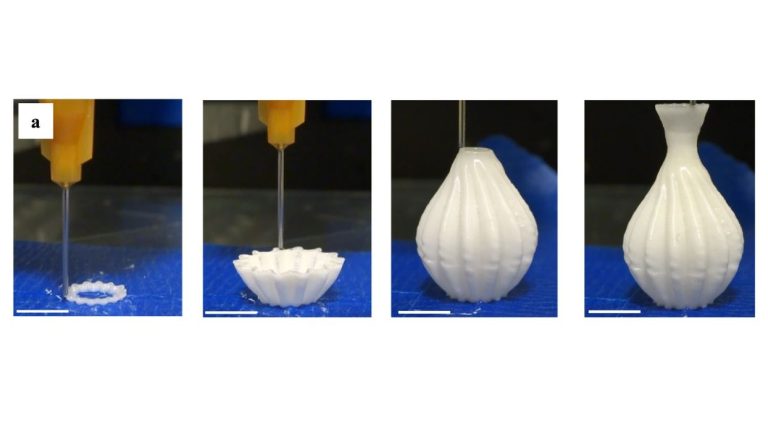

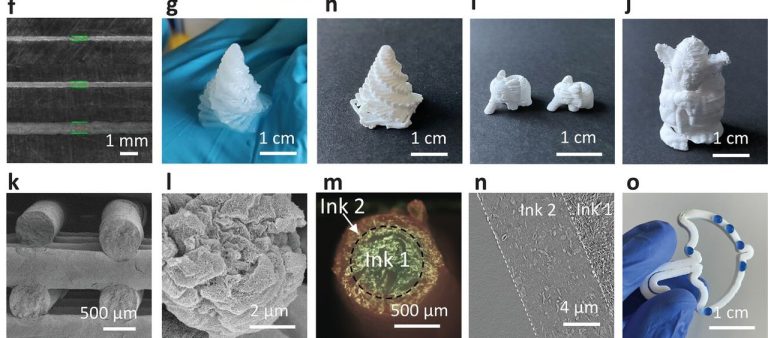

Innovative Direct Ink Writing Method Allows Variable Softness in 3D Printed Objects

Researchers have developed a unique approach to direct ink writing that has the ability to vary softness throughout the print.

Book of the Week: The 3D Printing Adventure

This week’s selection is “The 3D Printing Adventure” by Hargurdeep Singh.

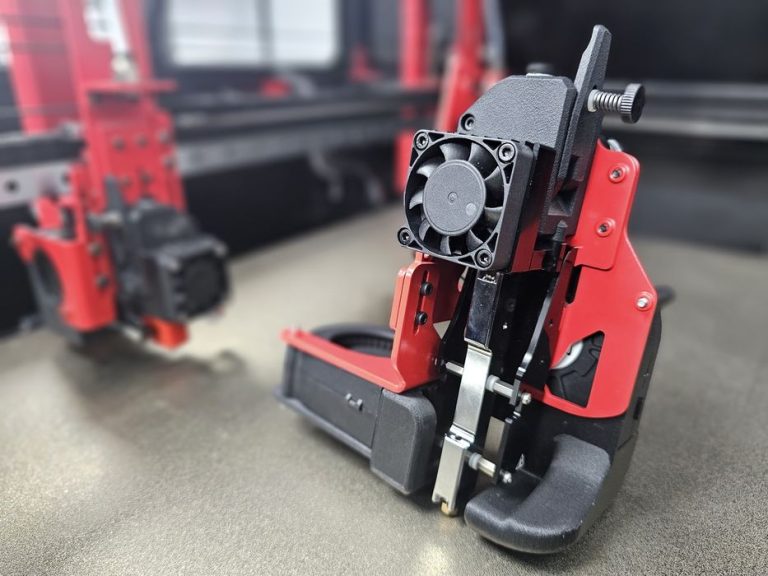

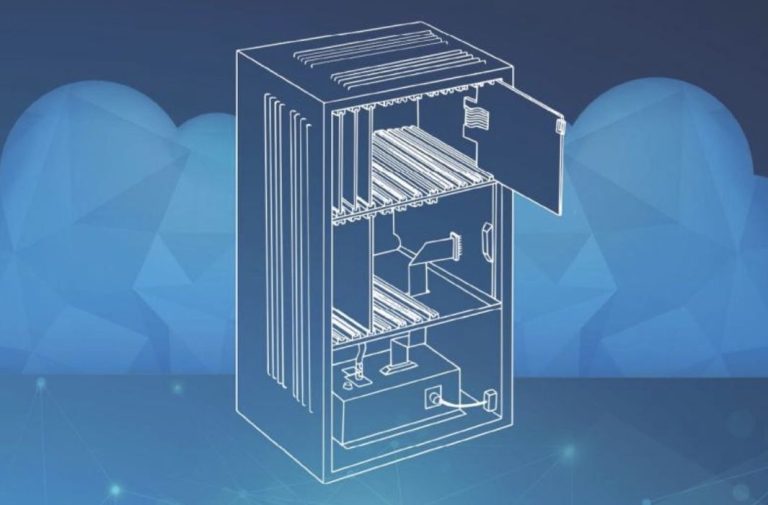

UltiMaker Launches Factor 4: Reliable and Repeatable 3D Printing for Industry

UltiMaker today announced a new flagship 3D printer, the Factor 4.

Modix Releases High Capacity Griffin Ultra Extruder for More 3D Printers

Modix continues its quest to optimize large-format FFF 3D printing with their new toolhead, the Griffin Ultra.

Stratasys Launches Direct-to-Garment Fabric 3D Printing System

Stratasys announced a new “direct to garment” solution for their fabric 3D printer, the J850.

Design of the Week: V-Spooler

This week’s selection is the V-Spooler by MakerWorld contributor Fyrby Additive.

Who’s The Biggest In 3D Printing, April 21, 2024

Once again we take a look at the valuations of the major 3D printing companies over the past week.

Sovol Launches New SV08 3D Printer: Large Build Volume, High Speed, and Seven-Axis Motion

Sovol launched what might become a very popular desktop 3D printer model: the SV08.

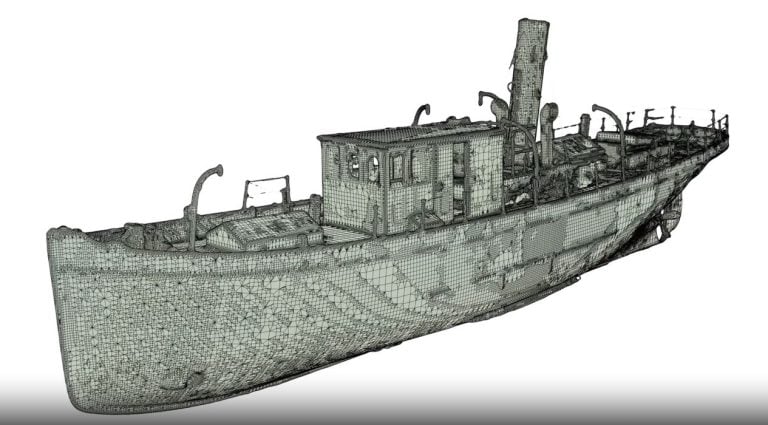

Rhino3D 8 Revolutionizes 3D Scanning with Innovative Shrinkwrap Function

Robert McNeel & Associates has released a new version of Rhino3D, version 8.

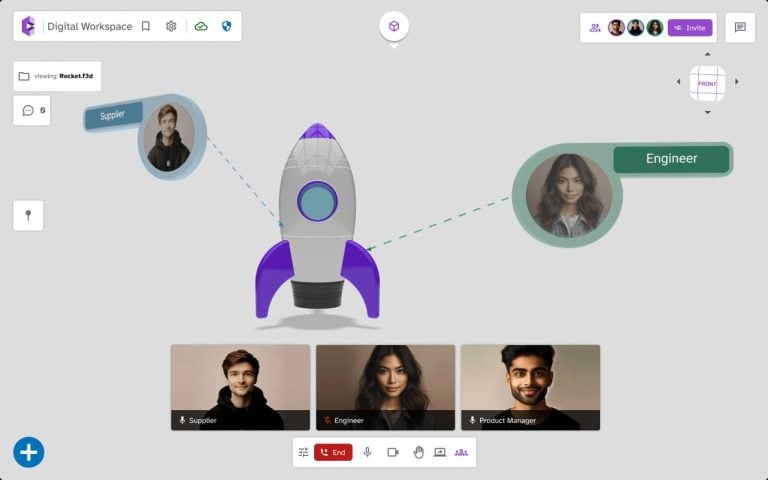

Enhancing Design Reviews: CADChat Combines Communication and 3D Viewing

A new tool for product designers has been launched: CADChat.

How to Optimize Shot Peening Parameters to Enhance Fatigue Performance

New research systematically compares effects of different shot peening parameters, including surface roughness, residual stress and strain profiles.

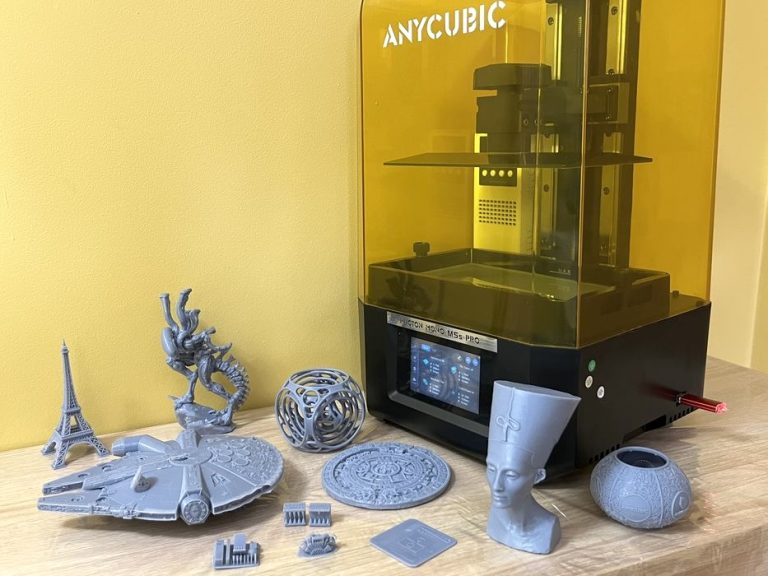

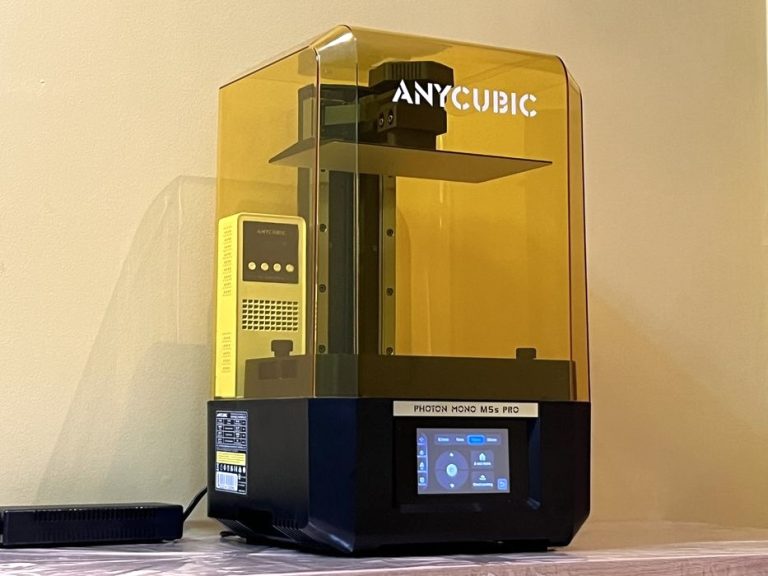

Hands On With The Anycubic Photon Mono M5S Pro, Part 3

Our review of the new Photon Mono M5S resin 3D printer from Anycubic concludes with a look at software, print results and final thoughts.

Hands On With The Anycubic Photon Mono M5S Pro, Part 2

Our hands on review of the new Photon Mono M5S resin 3D printer from Anycubic continues with a look at setup, calibration and operations.

Hands On With The Anycubic Photon Mono M5S Pro, Part 1

We performed an extensive test on the new Photon Mono M5S resin 3D printer from Anycubic.

Running Towards Innovation: Zellerfeld’s 3D Printing Fashion Statement

Charles R. Goulding and Preeti Sulibhavi discuss Zellerfeld's intricate 3D printed designs.

Formlabs Debuts Form 4 Series: 3D Printing with Enhanced Speed and Reduced Costs

Formlabs announced their fourth-generation line of 3D printers today, the Form 4 and Form 4B.

CNSA’s Experimental 3D Printed Storage Tank Proves Successful in Lunar Mission

There was an interesting 3D print development from the China National Space Administration (CNSA).

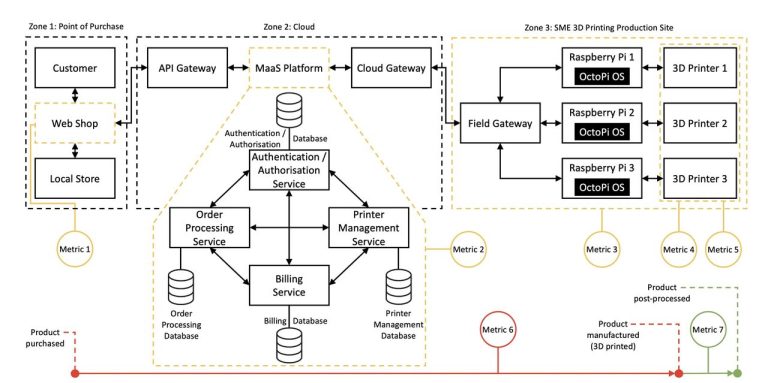

Researchers Explore the Cost and Benefits of Manufacturing as a Service

A new paper explores the idea of Manufacturing as a Service (MaaS).

3D Systems Achieves 510(k) Clearance for PEEK Cranial Implants

The FDA has approved the 3D printed, patient-specific VSP PEEK Cranial Implant solution.

Anycubic Launches New Color-Switching 3D Printer, High Speed Resin 3D Printer and Online Community

Anycubic released a cascade of announcements yesterday on advanced 3D printers, materials and even an online service.

Axtra3D Focuses on Practical Applications with Its HPS 3D Printing Process

I had a chat with Axtra3D and learned the company has taken a step forward.

Funding Tips for Emerging 3D Printing Entrepreneurs

3D printing has shaken up the world of fabrication and allows more people to get into design and engineering.

Book of the Week: Introduction to Electronic Packaging

This week’s selection is “Introduction to Electronic Packaging: Unconventional Guide to Product Design” by S.A. Srinivasa Moorthy.

GreenBoy3D Updates Pellet Extrusion Project for Desktop Printers

Kristian Friesen, a.k.a. “GreenBoy3D”, has provided an update on his pellet extruder project.

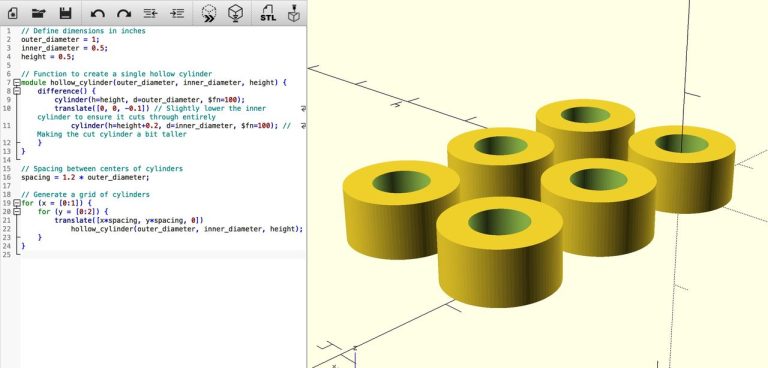

Exploring the Potential of Voice-to-3D Modeling

Could you use voice commands to generate 3D models? It turns out you can – for free!

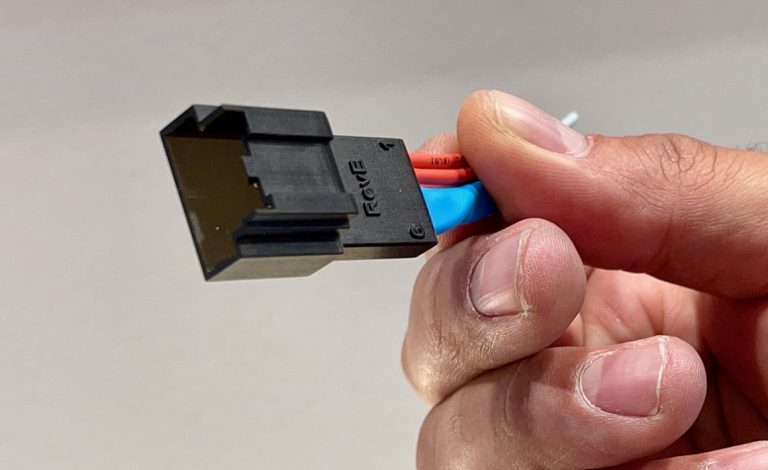

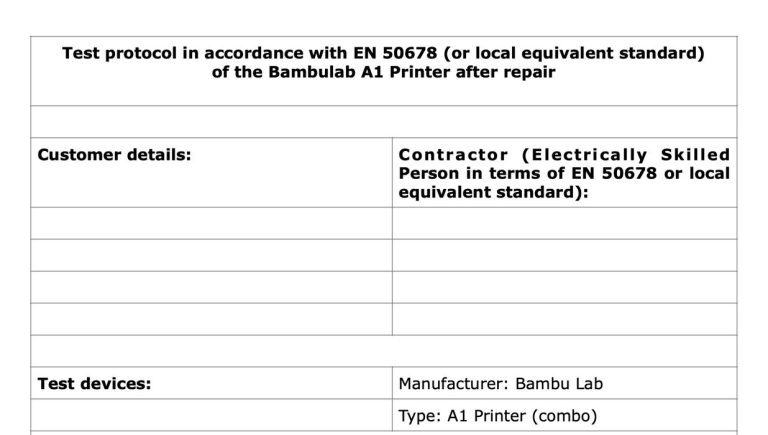

Bambu Lab’s A1 Recall in EU Stirs Confusion Over Electrical Certification Requirements

A minor controversy over the Bambu Lab A1 recall kit has erupted in Europe, but it seems to be an overreaction.

Design of the Week: Easter Chocolate Egg

This week’s selection is the Easter Chocolate Egg by industrial designer Marta Ribera Bellmunt.

Who’s The Biggest In 3D Printing, April 14, 2024

Once again we take a look at the valuations of the major 3D printing companies over the past week.

Creating Sustainable Homes Using Plastic Waste: An Interview with Dr. AJ Perez

Charles R. Goulding and Preeti Sulibhavi chat with Dr. AJ Perez, a distinguished MIT-trained engineer, entrepreneur, and sustainability advocate.

Creality Marks a Decade in 3D Printing with Multiple New Product Launches

Creality celebrated their tenth anniversary this week, something few desktop 3D printer manufacturers have been able to achieve.

Stratasys’ Second ESG Report Highlights Sustainability Progress

Stratasys issued their second ESG and Sustainability report.

VIPS-3DP: A New 3D Printing Technique Using Vapor for Solidification

Researchers have developed a new and potentially very powerful new 3D printing process they call VIPS-3DP.

3D-Printed Valve Assemblies Now in Production for US Navy Submarines

Fairbanks Morse Defense will produce a 70-lb copper-nickel valve assembly made with additive manufacturing in a fraction of the time compared to sand casting.

Creality Launches K2 Plus with Multicolor Capabilities

Creality announced a new desktop 3D printer with a color-changing attachment.

Automatic Tuning Breakthrough: The 3D Printer That Adapts to Any Filament

Researchers have achieved a major breakthrough: a 3D printer that automatically tunes itself.

Are ISO-Certified Biocompatible 3D Printing Filaments Truly Safe?

With the announcement of a new set of biologically safe filament materials, it’s time to talk about what that means.

Feeding the Final Frontier: How 3D Printing is Redefining Space Food

Charles R. Goulding and Preeti Sulibhavi explore 3D printing for space food production.

Exploring Farsoon’s FS621-M: A Giant Metal 3D Printer

We had a look at one of Farsoon’s biggest metal 3D printers, the FS621-M.

Researchers Strengthen 3D Printed Cellulose Aerogels with Carbon Nanofibers

Researchers have identified a method of 3D printing cellulose aerogels with greater strength.

Slant 3D Launches API for Direct Access to Print Farms

News from Slant 3D: they’ve developed an API for developers to directly access their print farm.

Filamentive Launches UK’s First 3D Print Waste Recycling Scheme

Aiming to address the issue of plastic waste in the industry, starting with PLA.

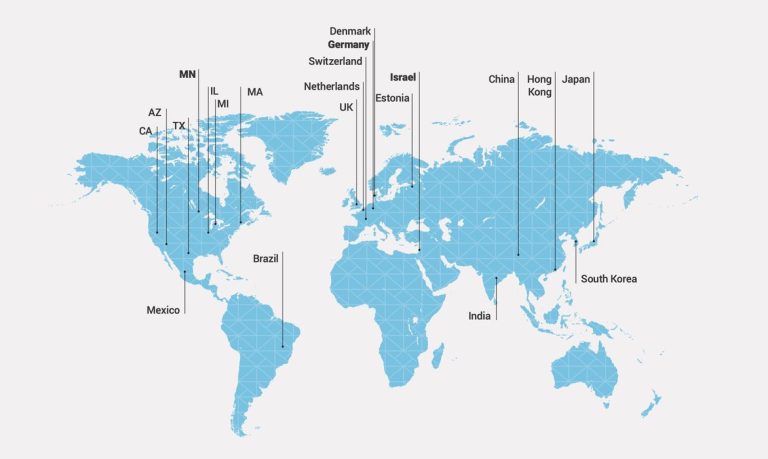

Navigating Supply Chain Disruptions: Leveraging 3D Printing for Global Resilience

Charles R. Goulding and Preeti Sulibhavi consider 3D printing as a potential solution amid ongoing global supply chain disruptions.