At this year’s SOLIDWORKS World, Dassault Systèmes has demonstrated that it’s ready for the world to start designing for additive manufacturing (AM)—and not just traditional 3D printing technologies, but some of the newer, potentially more functional processes on the market.

As noted in our coverage of the release of HP’s full-color 3D printers, future versions of SOLIDWORKS will make it possible for users to design specifically for HP’s Multi Jet Fusion (MJF) technology. This won’t be the same as creating full-color parts made with binder jet or inkjet systems. Instead, it will encompass “voxel-level” control, as HP likes to refer to it. That is, it will provide the ability to print different inks at the scale of a three-dimensional pixel.

More immediately, this means the color of every point within a 3D-printed object, but in the future, it will apply to functional agents that HP will be releasing, such as conductive inks, elastomers and quantum dots.

The software’s embrace of multi-material 3D printing doesn’t stop with MJF. It also includes printed circuit board (PCB) manufacturing with the DragonFly 2020 Pro system from Nano Dimension. Nano Dimension’s technology is capable of 3D printing conductive material within a 3D polymer part, opening up PCB designers to new shapes and dimensions that were previously not possible. Now, users will be able to 3D print these materials directly within the software, potentially reducing design errors and speeding up fabrication time.

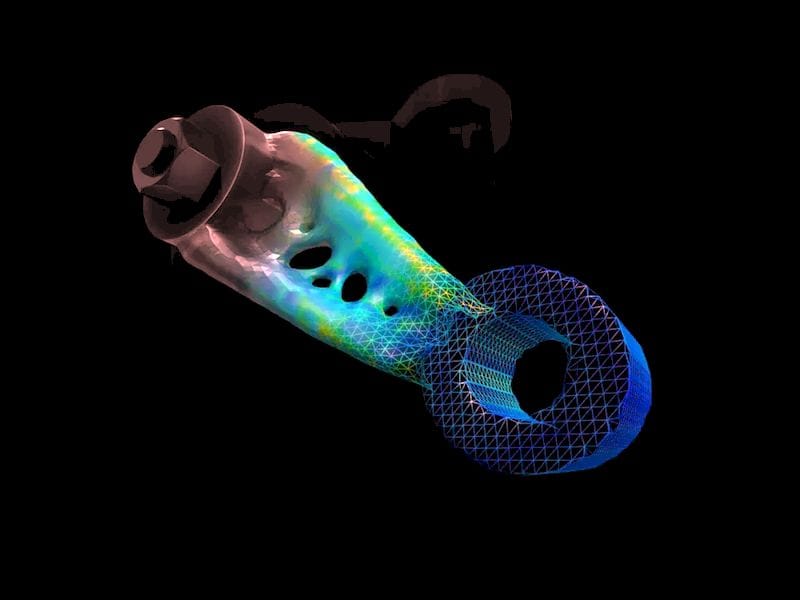

Beyond materials, the software will also embrace new design methodologies, specifically generative design. Whereas Siemens is integrating generative design into its software via tools developed by Frustum and the Autodesk acquired company netfabb for its own topology optimization software, Dassault Systèmes has partnered with Desktop Metal. SOLIDWORKS users can now preview Desktop Metal’s tool, Live Parts, which relies on a graphics processing unit (GPU)-accelerated multi-physics engine to automatically generate weight optimized parts in real-time.

Read more at ENGINEERING.com