Fabbaloo has obtained 3D print samples from printer vendor Solido, including the dramatic skeleton hand above. Solido uses a unique plastic sheet printing technique in which successive sheets are glued and cut, eventually building up to an object. This process certainly produces a lot of waste plastic – but don’t fear! You can send the unused plastic sheet clippings back to Solido, who recycle them for you.

Fabbaloo has obtained 3D print samples from printer vendor Solido, including the dramatic skeleton hand above. Solido uses a unique plastic sheet printing technique in which successive sheets are glued and cut, eventually building up to an object. This process certainly produces a lot of waste plastic – but don’t fear! You can send the unused plastic sheet clippings back to Solido, who recycle them for you.  We were amazed at the quality of the prints. Here we can see the fine details of the hand bones (click for more detailed view). While there is some very fine layering visible and touchable as you can see in the image above, the shimmery visual quality makes it a memorable object.

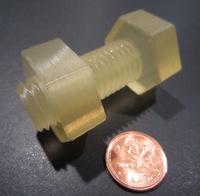

We were amazed at the quality of the prints. Here we can see the fine details of the hand bones (click for more detailed view). While there is some very fine layering visible and touchable as you can see in the image above, the shimmery visual quality makes it a memorable object.  Solido included a nut and bolt to illustrate the fine detail possible with their system. The nut fits and turns very well, although we’re not sure of the fragility of this sample and don’t want to find out via experimentation. Perhaps it’s the almost clear view through the bolt that makes one feel that the object is glass-like?

Solido included a nut and bolt to illustrate the fine detail possible with their system. The nut fits and turns very well, although we’re not sure of the fragility of this sample and don’t want to find out via experimentation. Perhaps it’s the almost clear view through the bolt that makes one feel that the object is glass-like?  The final object we’d like to show is this Round Clip, which functions rather smoothly. The material is sufficiently bendable and strong to lock together strongly when the teeth are engaged. Even better, the huge flexibility of the clip would easily permit insertion of something the width of the opening. Very well done!

The final object we’d like to show is this Round Clip, which functions rather smoothly. The material is sufficiently bendable and strong to lock together strongly when the teeth are engaged. Even better, the huge flexibility of the clip would easily permit insertion of something the width of the opening. Very well done!Our thanks to Solido USA for providing the samples!

Via Solido