Editor: This is a guest post courtesy of well-known 3D Printing blogger Joris Peels. Most recently Joris was the Community Manager for Shapeways, but these days he’s blogging at VoxelFab. This is part two of a two-part post. You may read part one here.

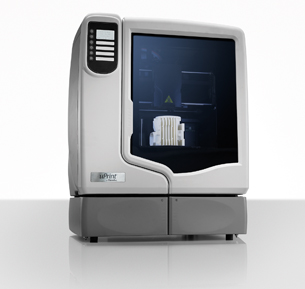

The Dimension uPrint Plus (a.k.a. HP Designjet)

The Dimension uPrint Plus (a.k.a. HP Designjet)Don’t get the entry level uPrint, it only has one material color. The Dimension 3D printers work on FDM (Fused Depostion Modeling) technology that takes a thin strand of ABS plastic and builds up your models layer by layer. The support material is dissolved in a soda bath. FDM usually does not make for very pretty 3D printed parts. However the technology does have the highest dimensional accuracy & strength. The Dimension systems are the easiest to operate in an office environment & support material removal is also comparatively easy.

The Plus costs $16,000 & the HP Designjet, which is the same printer, is around that price.

The Good

- Ease of use

- Strong parts in ABS

- Highest dimensional accuracy

- Easy support material removal

- No post processing needed

The Bad

- Parts are not pretty

- Separate soda bath station required

Recommendation

This would be less suited for elaborate client pitches. It would be eminently suited for internal testing of functional parts and more engineering focused firms.

Also look at:

The Dimension Elite. Although larger and more expensive at $22,000 this is the tried and trusted Dimension printer with a larger build volume & more detail.

Dream Customer: Foster + Partners

The Objet Alaris 30 is relatively expensive at around $40,000. Objet systems use a photopolymer that is hardened by UV light. Support material has the consistency of hard hair gel and can be removed by water jet. The technology is very accurate with very fine layers and the parts made with is look very arty. The parts are however not very strong and begin to melt at 58 Celsius.

The Good

- Highest detail

- Pretty looking parts

The Bad

- Parts not strong

- Material is proprietary technology so least understood

- I’m meltinggggg

- Support removal can be very tricky with some interior spaces

- Separate water jet station required.

Recommendation

This would be the system I would re commend to a creative “space & form” focused architectural firm. Art and design objects look good coming from Objet machines and the level of detail makes a lot of people go “wow.” The parts are however not very strong so less suitable for shipping around the world.

Dream Customer: OMA

I hope I’ve begun to illustrate that there really isn’t a “best” 3D printing technology out there. It all depends what kind of parts you need and what you want to do with them. When buying a system make sure you understand and have the capability to master every production step. For this investment to make sense you need people in house that know how to design for 3D printing, know how to repair and nest designs & now how to remove support material from parts. Understand the total time it will take you to get a model. Things such as “build speed” are quite irrelevant if one model must cool off for 24 hours and the other must not for example. Also look into service bureaus and compare the total costs of ordering from them & time to get your part versus owning your own printer. Many people forget to factor in labor, an important cost factor. From the outset look at the total price of the system and all the parts you need. Some systems need curing & post processing units that increase the cost by half or more. Most important of all get your hands on as many parts as you can from the different technologies you are evaluating. Touch them, play with them, test them, break them, leave them on your desk and ask everyone for feedback & print out the actual parts you would need for your business. If you do these things the best 3D printer for you should become clear.

You can follow Joris Peels on Twitter here or read his 3D printing blog VoxelFab here.

I wish I could comment with an in depth perspective on this one but I am really just barely scratching the surface of 3d printing.I have the HP design jet and as of now I am still getting to know more about its strength and weaknesses. Thank you very much for your help.

I wish I could comment with an in depth perspective on this one but I am really just barely scratching the surface of 3d printing.I have the HP design jet and as of now I am still getting to know more about its strength and weaknesses. Thank you very much for your help.