While there have been several experiments attempting to achieve the almost unbelievable feat of printing actual human organs, there has been a breakthrough development by researchers at Cornell. The title of their paper tells it all: “Direct Freeform Fabrication of Seeded Hydrogels in Arbitrary Geometries”. Ok, maybe that’s not entirely clear. Here’s how we’d interpret this: they’ve invented a method of printing living cells in almost any shape.

While there have been several experiments attempting to achieve the almost unbelievable feat of printing actual human organs, there has been a breakthrough development by researchers at Cornell. The title of their paper tells it all: “Direct Freeform Fabrication of Seeded Hydrogels in Arbitrary Geometries”. Ok, maybe that’s not entirely clear. Here’s how we’d interpret this: they’ve invented a method of printing living cells in almost any shape. Previous experiments were able to produce complex shapes, but the approaches they used were not ideal: pre-printing a dissolvable scaffold on which to deposit the cell-seeded hydrogel, or perhaps injection molding. These approaches require additional steps and thus are less convenient. They also cannot provide variation in cell type or density during deposition or easily be used for in situ fabrication.

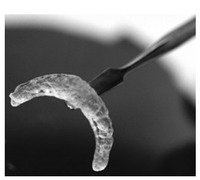

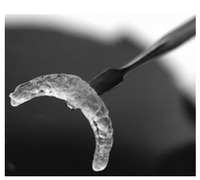

The new approach uses 3D printing techniques to deposit pre-seeded, cross-linked alginate hydrogel in layers, thus capable of complex arbitrary shapes. The new material meant that no subsequent steps were required and less fuss is required during the printing process.

The team’s experiments using what is essentially a specialized 3D printer with a syringe print head proved the viability of the deposited cells. In other words, the printed cells not only survived, but successfully bonded together.

We think this is a significant advance, and it may lead to a future where cells can be cultured, collected and then printed not only in the desired shape, but also directly on the spot where they need to be.