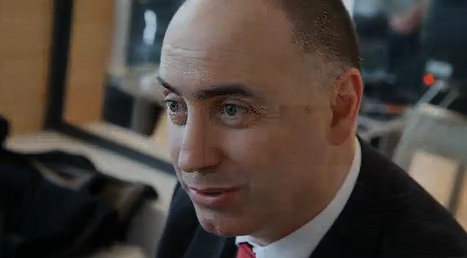

MCOR chief Conor MacCormack was interviewed by German IT news site Golem, in which he takes us on a detailed technical tour of their amazing paper-based 3D printer. Here’s the highlights:

MCOR chief Conor MacCormack was interviewed by German IT news site Golem, in which he takes us on a detailed technical tour of their amazing paper-based 3D printer. Here’s the highlights:- Up to 3 full reams of common A4 paper is accepted by the machine

- Sheets are fed, one-by-one, into the build chamber (or should we say cutting chamber?)

- The machine cuts with a microscopic tungsten-carbide blade that is adjustable on the micron scale to account for different paper thicknesses

- The cutter is so fine it is able to slice a page without disturbing the sheet beneath

- The chamber is 1500mm high, and that’s the maximum size of a build

- Adhesive (that sticks the layers together) is applied selectively to avoid waste

- Completed builds emerge as a full ream of paper; you must peel off the waste paper by hand to reveal the final object

- Proprietary software was shown, and it appears to offer similar features to other 3D printing control systems

You might think printing an object in this way produces a lot of waste. Well, it does – but remember, paper is recyclable, and it’s perhaps the least expensive print material we’ve seen.

Via Golem.de (in German, but English is spoken for most of the interview)