RepRap 3D printers are for hobbyists, right? For tinkerers who like to build their own machines? Not always, if you were to ask the brothers Kühling & Kühling, who produce the RepRap Industrial 3D printer.

This machine is a pre-assembled RepRap machine specifically designed for industrial use. What makes it so? We noticed multiple features:

- It’s big. The machine has a huge exterior size compared to typical RepRap machines, with a reasonably-sized build platform

- The build platform, and in fact the entire machine is enclosed in a well-lit, sealed chamber, which is heated to +70C for warp-free 3D printing in nylon or ABS for objects over 20cm in size

- It might seem that the build chamber could be larger, but it isn’t to permit heated air flow to circulate through the chamber

- Very heavy-duty internal components are used throughout

- High-capacity filament spools (up to 2.3kg each) can be mounted on the rear panel of the machine

- A “filament out” detector pauses prints to permit you to replace a spool

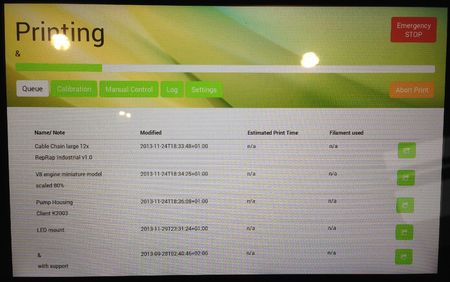

- An embedded computer spools incoming print jobs into a queue. While it doesn’t yet remove prints from the bed automatically, once you do the next job is ready to go

In addition to standard features such as 0.1mm resolution, dual extruders and network connectivity, the RepRap Industrial includes a very attractive touch screen connected to the embedded computer.

We’d class this device as a “professional” machine, suitable for heavy usage. Priced at €5,000 (USD$6,850), the machine is not inexpensive – but it will likely outlast several lesser machines.

If you want to buy one, be prepared for a bit of a wait. We understand there’s currently a sixteen-week backlog of orders, but that might drop as manufacturing capacity is increased.

I think they should have made a more distinct name than riding on the open source brand – and I think it might hurt more than it would help, actually.

I think they should have made a more distinct name than riding on the open source brand – and I think it might hurt more than it would help, actually.