With the expiration of key patents around photo-curable 3D printer techniques, we’ve seen several new resin-based personal 3D printer projects. Now another has emerged, the mUVe 1 from mUVe 3D, created as a part-time project by maker Michigan-based Dean Piper. The mUVe 1 is the first product from mUVe 3D, now seeking initial funding via an Indiegogo campaign.

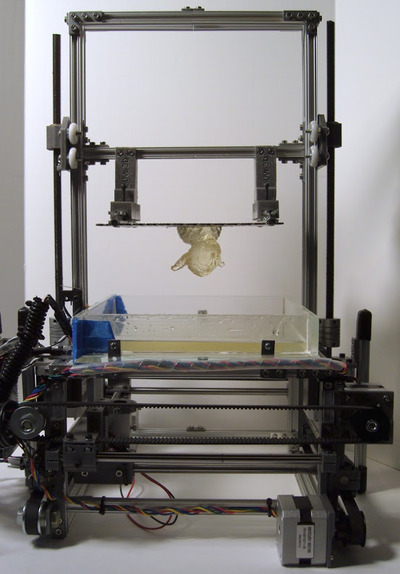

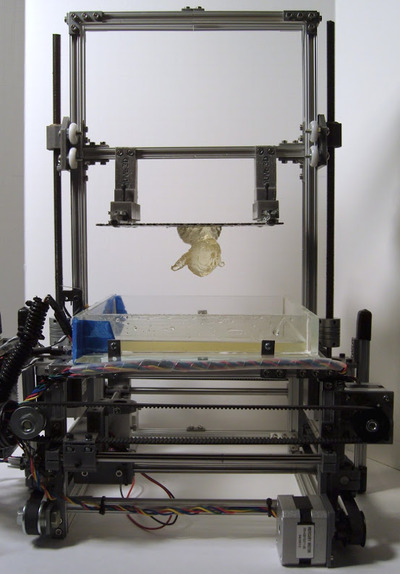

The mUVe 1 has been built in prototype form, seen without an exterior case above. The RepRap-powered device provides a reasonable build volume of 145 x 145 x 185mm, suitable for the majority of personal 3D prints.

There are several ways of photo-curing resin, but the mUVe 1 uses a 405nm laser. One intriguing feature is a “Laser Iris Diaphragm”, which “allows hugely scalable resolution, .1mm is tested and working.” That’s the promise of resin-based 3D printing: ultra-high resolution. It seems that the mUVe 1 delivers that.

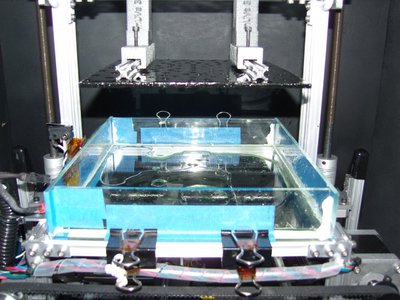

Our look at mUVe 3D’s progress so far is promising, but they’ve yet to solve a few issues, the most prominent being the design of the resin reservoir.

In the long term, mUVe 3D intends on selling parts to assist your own mUVe 1 construction projects to support their operations. Meanwhile today you can get involved by participating in their Indiegogo campaign, which actually looks like a pretty good deal: for USD$999 you can obtain a complete kit to build your own mUVe 1, a price lower than most other resin-based options.

The reservoir issues have all been solved, there is a FEP non-stick coating as well as a heat pad. You will notice the large difference in the reservoir in the top image compared to the bottom image. The top image reflects the reservoir in its current state. The final reservoir sent to customers will use an adhesive heat pad and won't have that ugly blue tape along the left-hand side.

The reservoir issues have all been solved, there is a FEP non-stick coating as well as a heat pad. You will notice the large difference in the reservoir in the top image compared to the bottom image. The top image reflects the reservoir in its current state. The final reservoir sent to customers will use an adhesive heat pad and won't have that ugly blue tape along the left-hand side.