The cost of a 3D printer is not only the printer itself, but also the print material. In most cases, personal 3D printers use plastic filament, either ABS or PLA plastic. If you’re a prolific 3D print maker, you might actually spend more on plastic than you did on the 3D printer.

How can this expense be reduced? You can shop around for the least expensive filament offered for sale, but another alternative might be the Filastruder. It’s a new device just launched on Kickstarter that allows you to make your own filament – at a much lower price.

The Filastruder project, by Tim Elmore of Florida, hopes to capitalize on the current price gap between filament and raw plastic pellets, from which filament is produced. Elmore suggests the price of filament can be ~USD$40 per kilogram, while raw plastic pellets can be had for only a “few dollars per kilogram”.

This is quite true. We took a quick look at sources of ABS pellets on Alibaba.com and found you could pick up large quantities of ABS pellets for as low as USD$1 per kg, if you’re willing to buy a ton at a time.

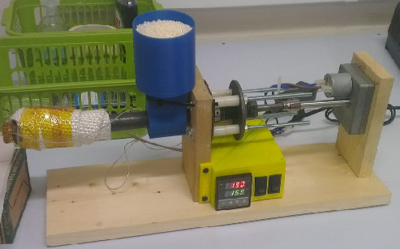

The Filastruder accepts such pellets, poured into a hopper, which then heats them to a precise temperature and then extrudes the melted plastic through an appropriately-sized nozzle to form filament. The filament collects on a spool which you can often drop directly into your 3D printer.

The Filastruder is certified for use with ABS pellets, while they are still tuning the settings to ensure consistently shaped PLA filament. The device can produce 2-5 pounds of perfectly shaped ABS filament per day and is capable of running for “hundreds of hours”.

The project was recently launched on Kickstarter with a fundraising goal of USD$5,000. Well, they are somewhat higher than that now, with well over USD$150,000 pledged.

Just think: for a mere USD$300 for the Filastruder and USD$1000 for a truckload of ABS pellets you’ll never need to buy any filament ever again. In fact, if you were to package up the filament and sell it, you might even make some money.

Via Kickstarter