If you’re using an extrusion-based 3D printer, you’re likely familiar with the problem of seams. It’s an annoying strip right up the side of your object that disrupts the otherwise smooth surface of your 3D print.

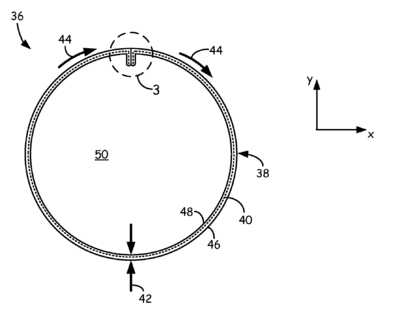

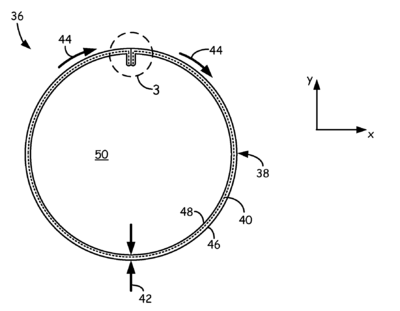

If you’re using an extrusion-based 3D printer, you’re likely familiar with the problem of seams. It’s an annoying strip right up the side of your object that disrupts the otherwise smooth surface of your 3D print. The seam is actually composed of the vertical accumulation of start / end points from each layer’s perimeter. The diagram above shows what happens on each layer. Typically they’re in the same place on each layer and visually this leads to a seam.

While we’ve all suffered from this phenomenon, Stratasys has solved the problem, at least partially. In a process they’ve patented published on April 18 of this year, they describe a way to avoid or at least reduce unbecoming seams.

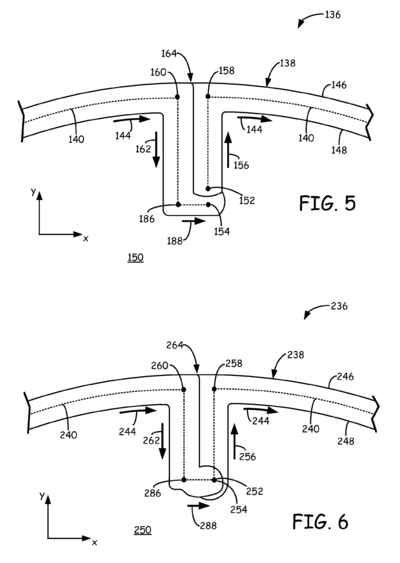

Their solution is to place the start and stop points for each layer’s perimeter on the interior of the print, not on the perimeter itself. You can see how it works in the image above. Stratasys has included several variations of this approach in their patent. They have or will incorporate this solution into their slicing software, which works only on their own 3D printers: the Mojo, uPrint and FORTUS lines.

Although this looks like a great solution – you can’t use it! It’s only available for Stratasys equipment and software. As they’ve just patented this process, this precise feature cannot be included in any open source (or any) slicing software without risk of committing patent infringement.

Via Google Patents

Wow! That's really awesome, I've already tried some hacks overwriting the generated g-code but if it's fixed in the software which generates it, it sounds way much better! Looking forward and hope that all the maker companies are going to follow the leader and adapt this invention into their firmware as well.

Wow! That's really awesome, I've already tried some hacks overwriting the generated g-code but if it's fixed in the software which generates it, it sounds way much better! Looking forward and hope that all the maker companies are going to follow the leader and adapt this invention into their firmware as well.