Should the new test-tube hamburger meat be 3D printed?

Short answer: yes.

Long answer: hold on, what are we talking about here?

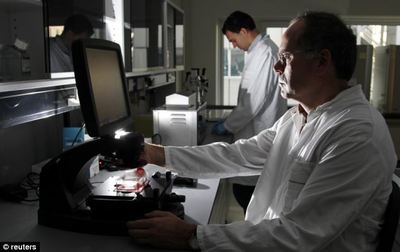

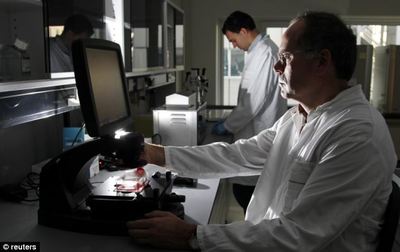

This week marks the debut of lab-cultured meat. It’s real beef, but the difference is that it did not come from cattle. It was produced by growing beef muscle tissue with real stem cells in a lab. The “burger” was made by painstakingly knitting the grown muscle fibres together into a coherent and appropriately textured beef burger structure. The cost of this delicacy? Only USD$380,000. For one.

Give them a break, it’s the world’s first. The next one will be somewhat less expensive.

Long answer for real: We suspect that lab-cultured food will gradually become economical to produce, particularly as population rises and arable farmland reduces. Brewing up lab-cultured meat should be free from common farm diseases and far less stray chemicals, as well as significantly reducing greenhouse gases involved in production.

The problem will be making structures suitable for the human palate. This first example involved arranging many thousands of millimeter-sized segments into a burger shape. Sounds much like 3D printing, doesn’t it?

We think future 3D printers could specialize in this function; extruded meat particles could be carefully arranged in unique and perhaps personalized forms.

Today’s BBQ chef asks the eaters whether they want theirs done “rare, medium or well”. Tomorrow they may ask for shape, size and texture, too.

Via DailyMail