You probably don’t know what a HOG Scrubber is. We didn’t either. It turns out it stands for “Hang On Glass” aquarium filter.

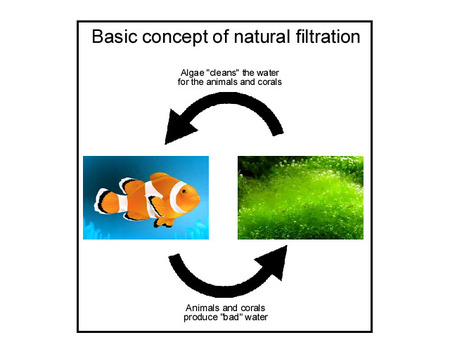

Ok, wait a minute, don’t aquariums already have filters? They do, but they are mechanical in nature and simply clog up, requiring cleaning or replacement. They also don’t get rid of dissolved chemicals. The HOG Scrubber is a special device that purposely grows algae in your tank that acts as a biological filter. The algae removes harmful chemicals and even provides food for tiny fishes.

Ok, wait a minute, don’t aquariums already have filters? They do, but they are mechanical in nature and simply clog up, requiring cleaning or replacement. They also don’t get rid of dissolved chemicals. The HOG Scrubber is a special device that purposely grows algae in your tank that acts as a biological filter. The algae removes harmful chemicals and even provides food for tiny fishes. This seems like a good idea, if you have an aquarium. But where does 3D printing fit in? It turns out that the designers originally intended on using conventional injection molding approaches to develop the two plastic pieces making up the HOG. They encountered severe design problems when working with the injection molders, who not only cost a great deal of money, but also required major redesigns of the unit.

Enter 3D printing: the team found they could easily 3D print the precise shapes required to make up the HOG. They realized the correct process was extruded filament, because:

- Optically fused resin continues to fuse in daylight (required for the algae) and becomes too brittle to use. They could not use Objet, Formlabs or 3D Systems SLA printers

- Powder-based 3D printers produced brittle and porous objects that were not appropriate

- PLA prints actually dissolve when left underwater for extended periods, so that was out, too

That left extruded ABS plastic as the only option, but it worked. They’re currently experimenting with different machine and service options to achieve this. It clearly demonstrates the idea that no 3D printer can make anything; you must select the 3D printing process to match the intended usage.

If you have an aquarium, you might consider backing this project. For as low as USD$145 you can have your own HOG.

Via Kickstarter