Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated an additive manufacturing method to control the structure and properties of metal components with precision unmatched by conventional manufacturing processes.

Ryan Dehoff, staff scientist and metal additive manufacturing lead at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, presented the research this week in an invited presentation at the Materials Science & Technology 2014 conference in Pittsburgh.

“We can now control local material properties, which will change the future of how we engineer metallic components,” Dehoff said. “This new manufacturing method takes us from reactive design to proactive design. It will help us make parts that are stronger, lighter and function better for more energy-efficient transportation and energy production applications such as cars and wind turbines.”

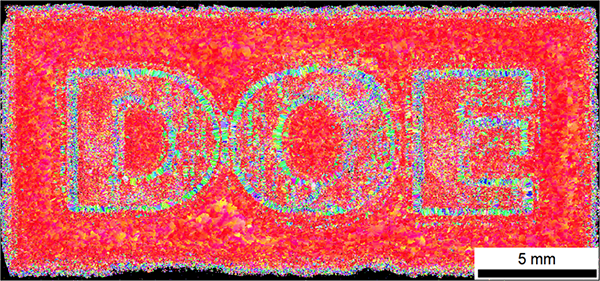

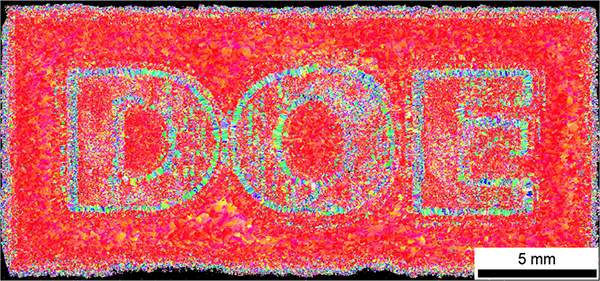

The researchers demonstrated the method using an ARCAM electron beam melting system (EBM), in which successive layers of a metal powder are fused together by an electron beam into a three-dimensional product. By manipulating the process to precisely manage the solidification on a microscopic scale, the researchers demonstrated 3-dimensional control of the microstructure, or crystallographic texture, of a nickel-based part during formation.

Read more at ENGINEERING.com