The Institute for Advanced Architecture of Catalonia (IAAC) of Barcelona has developed a set of experimental robots capable of building clay structures.

Termed “Minibuilders”, the concept involves three different kinds of building robots:

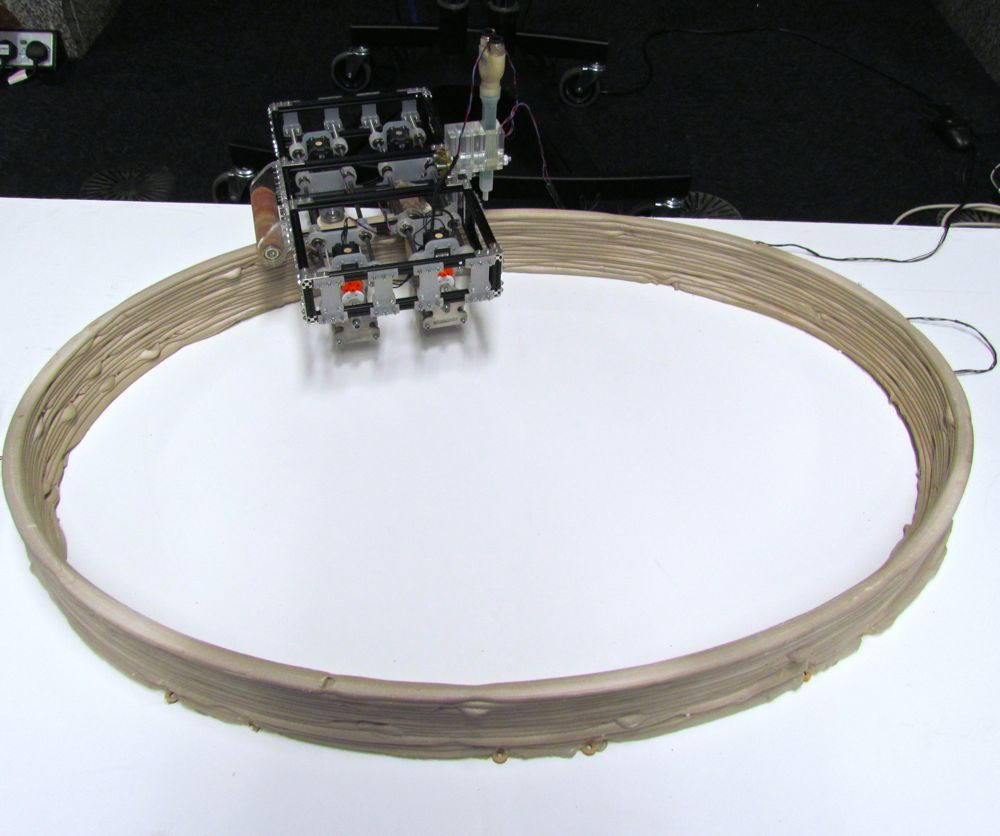

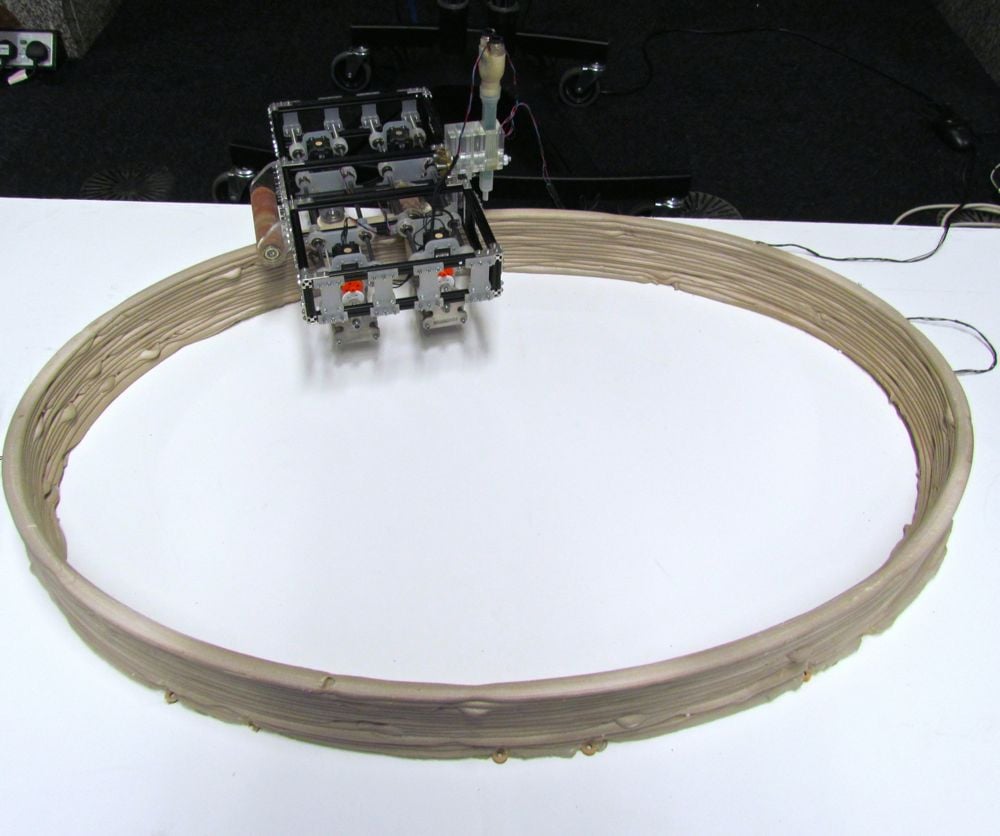

A “Foundation Robot” establishes the foundation of the construction through a smooth, spiraling extrusion:

The first ten layers create a foundation footprint. Sensors mounted inside the robot control direction, following a predefined path. Traveling in a circular path allows for a vertical actuator to incrementally adjust the nozzle height for a smooth, continuous, spiraling layer. The advantage of laying material in a continuous spiral is that for constant material flow, with having to move the nozzle up at intervals of one layer.

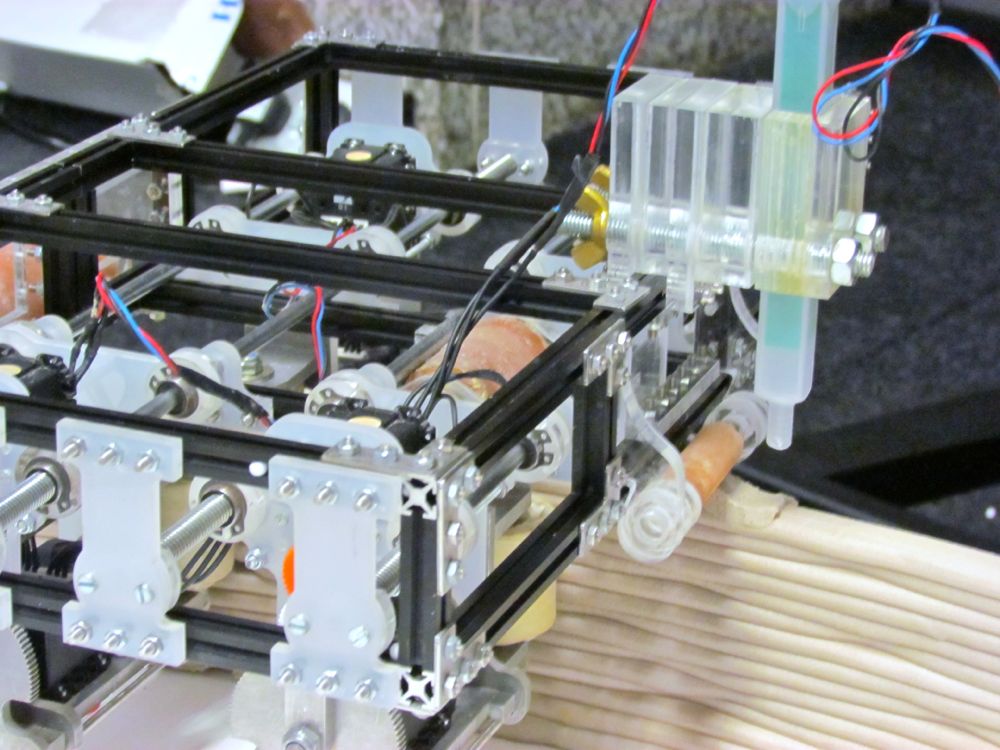

A “Grip Robot” creates the upper structure of the construction:

To create the main shell of the final structure the second robot attaches to the foundation footprint. Its four rollers clamp on to the upper edge of the structure allowing it to move along the previously printed material, depositing more layers. The nozzle moves dynamically allowing for greater accuracy of the material output, to create a curved surface the material output will be incrementally offset. Heaters integrated increase the curing process.

A “Vacuum Robot” uses a mathematical analysis of the structure to increase the strength of the final constructed object:

Using a vacuum, this robot attaches to the surface of the previously printed structure. Moving freely over the first shell on its tracks, depositing material on the surface of the shell, enhancing its structural properties. This task can be performed by one robot, or a swarm of robots working in coordination.

It’s a very dramatic concept that took seven months of research to complete. However, we have not seen any moves towards a commercial implementation of the concept, perhaps due to its complexity and undiscovered constraints. The Foundation Robot, for example, can build only as large as 260 x 350 x 370mm. If the concept worked on a small scale, would it work on a large scale, where there might be funding available from customers or investors? We think this project has much potential.

Via IAAC