We’re checking out a proposed new 3D printing process that could significantly lower the barriers to metal 3D printing: Selective Inhibition Sintering.

The concept was developed and published in a September 2014 paper by Payman Torabi, Matthew Petros, and Behrokh Khoshnevis of University of Southern California.

But first some background. Most metal 3D printing these days is performed by “Selective Sintering” or “Selective Deposition”. In Selective Sintering words a heat source (usually a high-powered laser) fuses together metal particles composing an object’s shape. In Selective Deposition a metal filament is melted and deposited at each location corresponding to the object’s shape.

The new process, “Selective Inhibition Sintering” (SIS) offers a very different method. Instead of fusing the object itself from a bed of metal particles, they merely deposit an inhibitor solution on the perimeter of the object. Then the powder bed is fired in a conventional furnace, melting and fusing metal particles that have not been inhibited. Inhibited particles remain loose.

This has multiple advantages over current processes:

- The liquid inhibiting solution can be rapidly deployed using well-known inkjet technologies at very high resolution.

- Liquid deposition requires very little power compared to lasers or high-voltage arcs used in other processes.

- Printing can be much faster due to the speed of inkjet tech and the fact that a furnace fuses the entire object simultaneously.

- Objects made using SIS are stronger as the fused metal particles have no binders or additives, and the melting process temperatures can be precisely controlled.

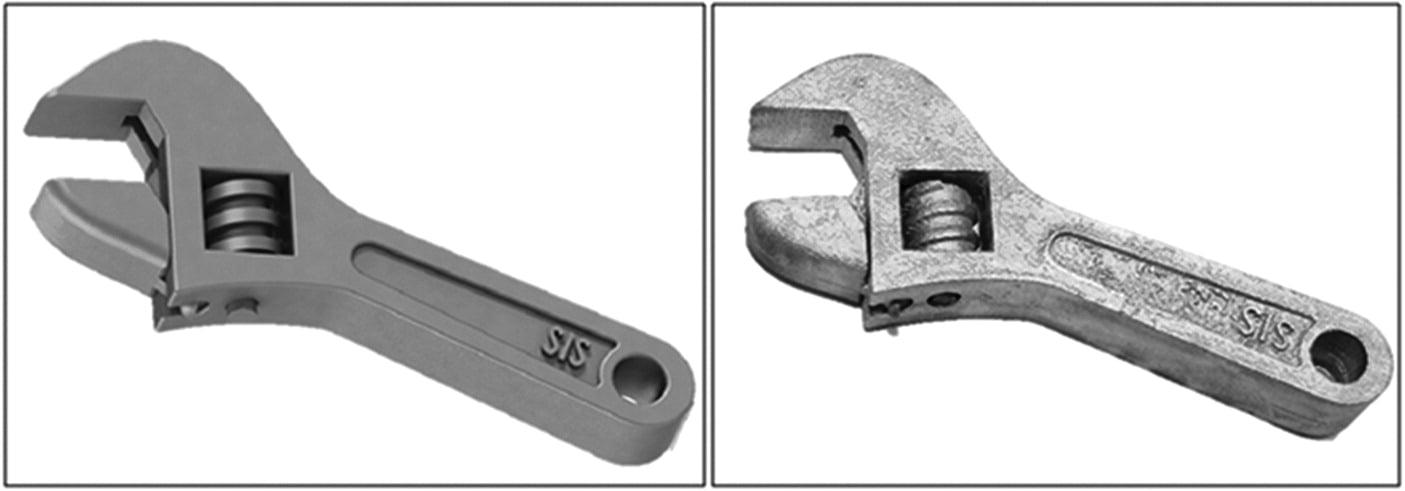

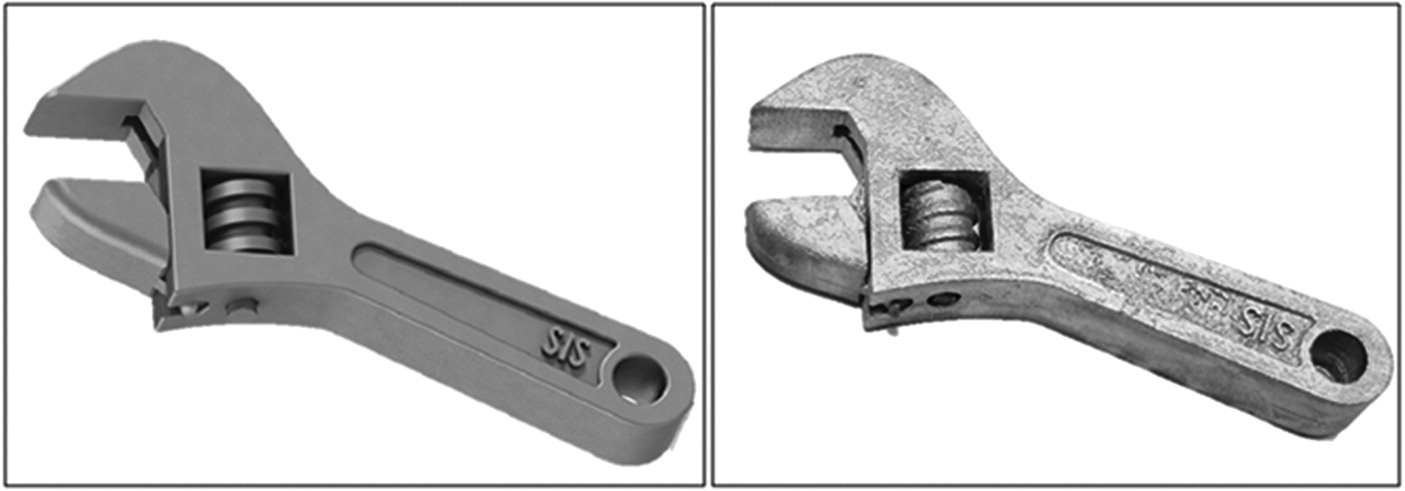

The team has built a prototype machine capable of employing SIS and have actually produced several usable metal objects, such as the wrench pictured above.

We have little doubt the new process will shake up the 3D printing metal industry, once it’s commercially deployed. It’s probably 3D metal printers will be developed that could be dramatically less expensive – and more effective.

Via Liebert