Founded in 2002 in Gladbeck, Germany – EnvisionTec has created some of the most accurate and reliable additive manufacturing systems on the market.

While EnvisionTec has a number of 3D printer lines, including a new bio-printing technology, the company’s most viable industry machine is its Xede 3SP.

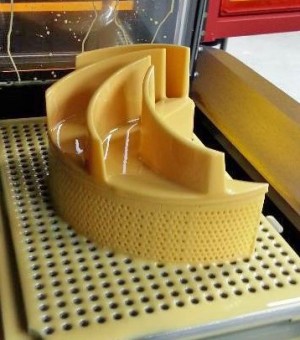

Showcasing the firm’s largest build volume, the Xede 3SP was designed to satisfy the needs of industries ranging from aerospace to jewelry. Accuracy is at the heart of the Xede design – and helps it stand apart from many of its industrial counterparts. Xede’s finished products display no visible stair-stepping and have been used in mold-making, hearing-aid production and even for Hollywood productions.

How the Xede 3SP Works:

Built into the name of the Xede 3SP is the key to its production technique. 3SP references its Scan, Spin and Selective Photocuring technique, whereby the Xede 3SP uses a multi-cavity laser diode and a rapidly spinning orthogonal mirror to build models.

Another important aspect of the Xede 3SP is its upgraded Imaging Light Source (ILS), which encompassed the system’s laser diode and optics. When in action the ILS passes across a vat of photopolymer at a rate of 1-2 inches per second, curing any region specified by a user.

Given this technology, EnvisionTec has been able to expand its build areas too, lending Xede the ability to create models that are 254 x 381 x 330 mm (10 x 15 x 13 in).

Read more at ENGINEERING.com