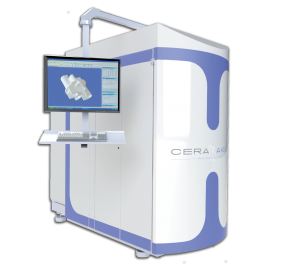

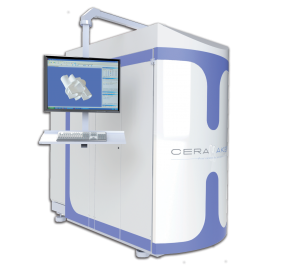

The CERAMAKER 3D printers from 3DCeram are able to print ceramic components.

A fourteen-year old company, 3DCeram has developed a stereolithographic process for 3D printing ceramic materials. The process involves a UV laser beam that fuses a photocurable resin that’s mixed with ceramic powder. The process continues layer by layer to create fully 3D ceramic objects. To finish the print, a sintering cycle eliminates the solidified resin, leaving only ceramic. The ceramic is “densified” to 100%, completing the ceramic print.

This process was originally researched by the French government in the 1990s, but taken on by 3DCeram later. They released their first 3D printer in 2006. Today, the CERAMAKER uses a similar process to create ceramic 3D objects.

The CERAMAKER’s build volume is 300 x 300 x 110mm, but is a large unit weighing 1,450kg (3200 lbs), requiring 2kW of 220V power. It’s able to print ceramic layers as small as 0.01mm, ensuring a very smooth finish on all prints. The CERAMAKER is priced at around €300,000 (USD$365,000).

This past summer 3DCeram signed a partnership deal with Prodways, who apparently will “disseminate ceramic 3D printing technology” in a way to increase sales of 3DCeram’s technology.

Via CERAMAKER