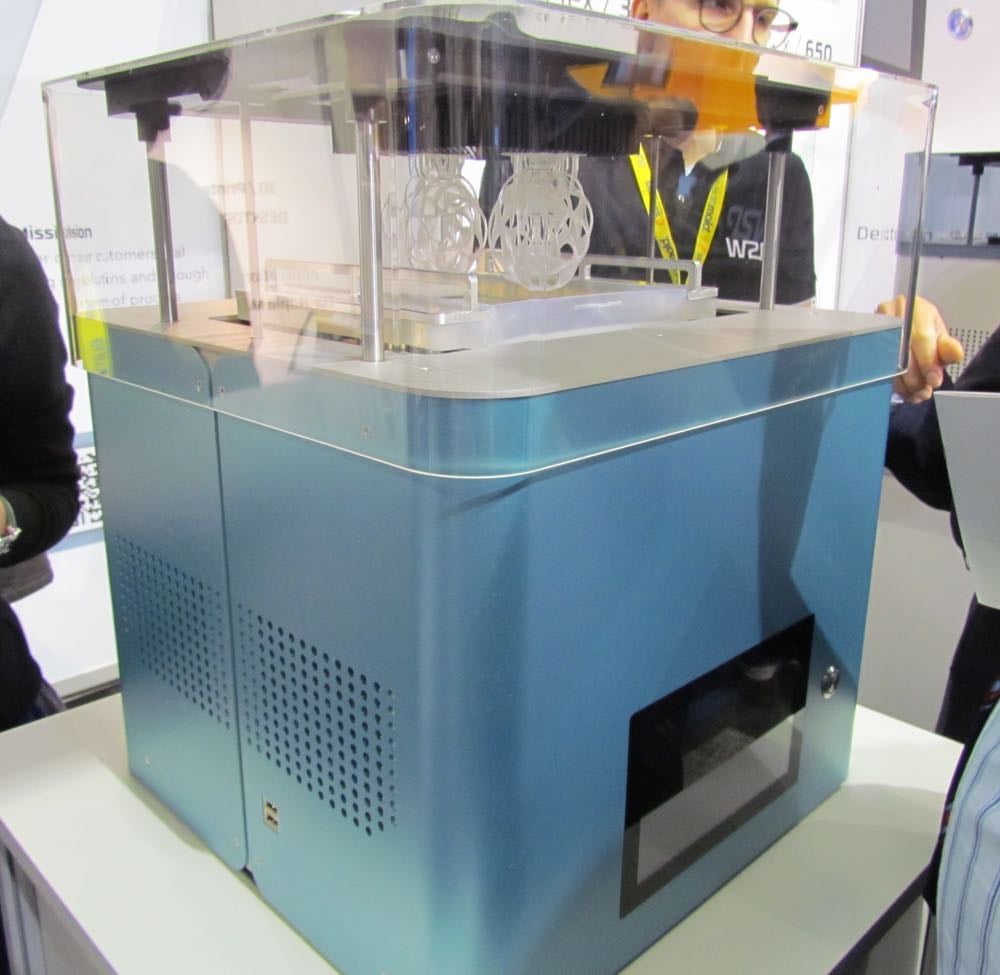

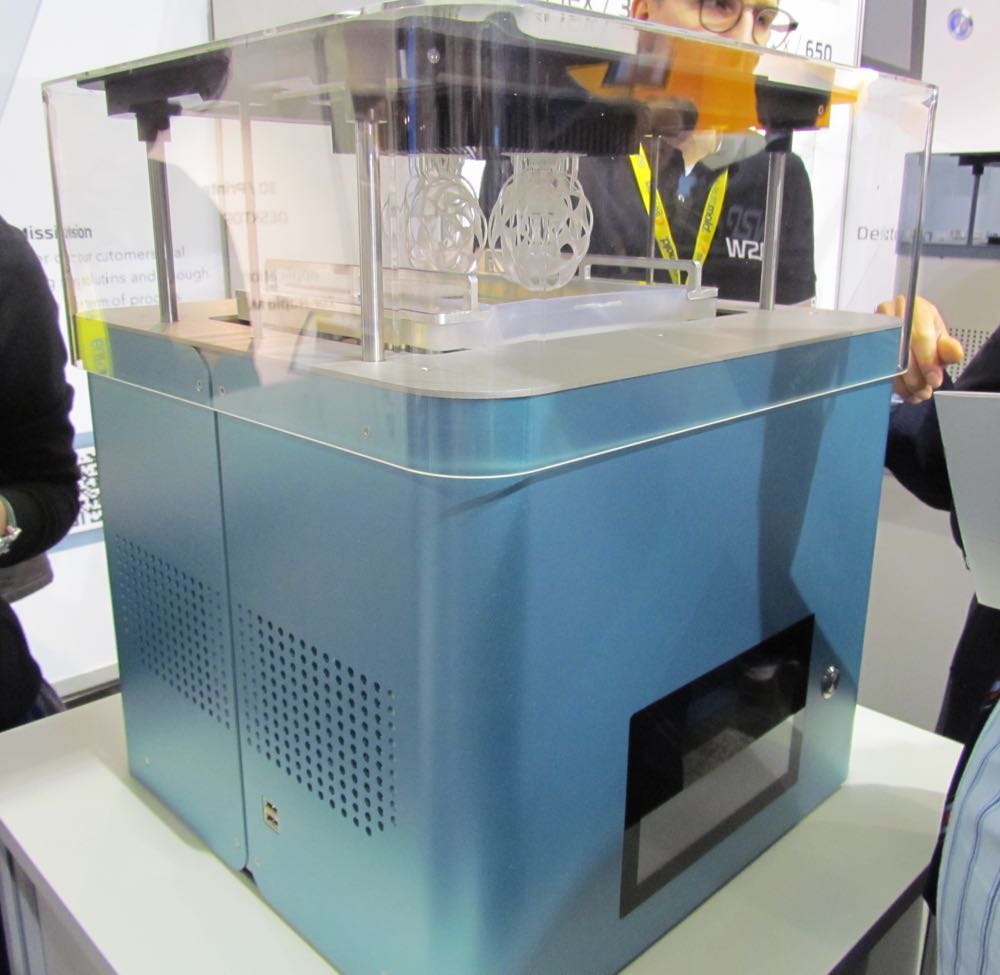

We’re checking out a pair of brand-new resin-based 3D printers from Way2Production: the SolFlex series.

We examined the two DLP-powered resin 3D printers from Austrian Way2Production, which were being shown to the public for the first time. Their technology attempts to breakthrough one of the critical barriers to production 3D printing: producing ultra-high resolution objects with large size. Typically DLP-based solutions have reduced resolution when the object size is increased: the same number of pixels is simply spread over a larger print layer.

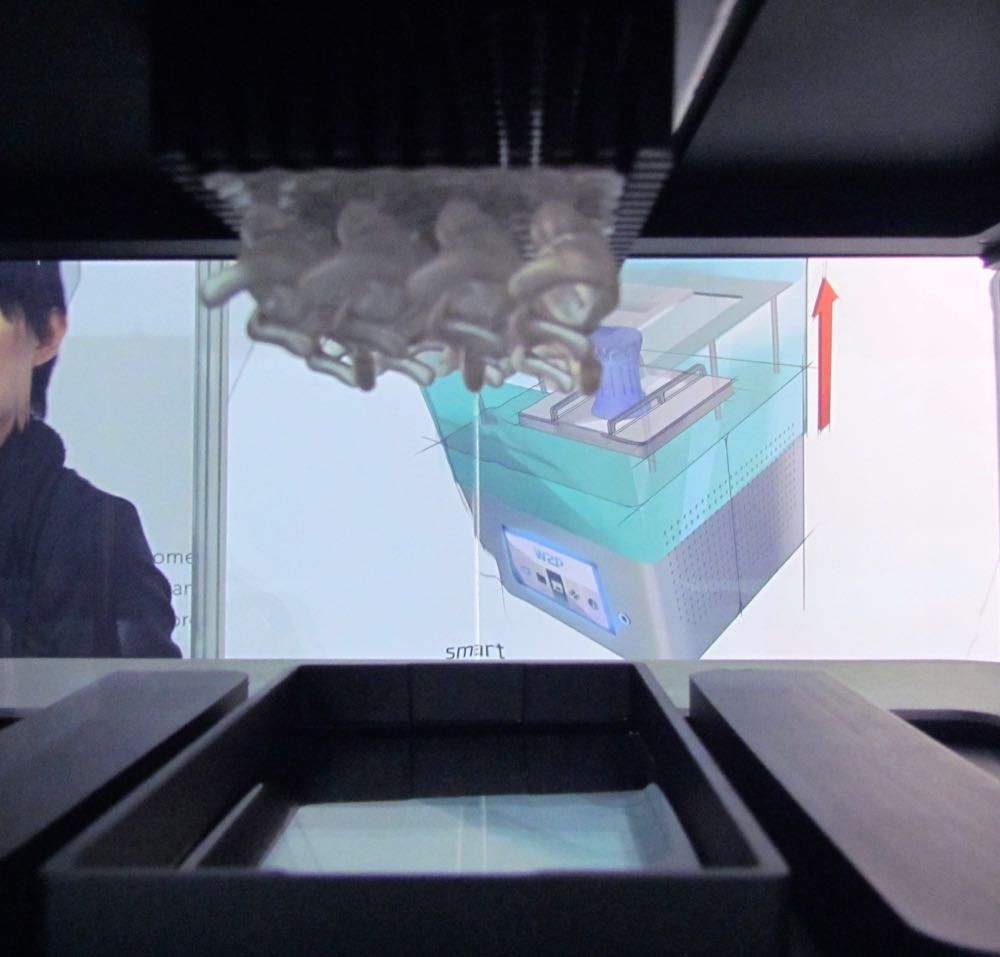

Way2Production overcomes this restriction by performing “pixel stitching”. In other words, once part of the print area is illuminated by the DLP projector, the projector shifts and a second portion is illuminated. Thus, we have more pixels illuminated per layer than are projected by the DLP projector. More pixels means a larger object with the same resolution – which is 50 micron (0.050mm) sized pixels.

Two configurations are offered: the SolFlex 350 and SolFlex 650. The key difference between the two is in the maximum build volume. The 350 provides a 64 × 120 × 110mm volume, while the 650 offers 128 × 120 × 110mm.

Each machine offers a unique flexible surface for low-force object release after printing completes.

One feature we quite like is that the machines can accept any third party resin, although Way2Production has designed their own suite of resins for various applications, including biocompatible (dental, hearing aid and clear), investment casting (jewelry and larger parts), and general purposes (clear and modeling).

Oh yes, there’s one more difference: the anticipated price level of the 350 is €25,000 (USD$31,000) whereas the 650 is expected to hold a price of €35,000 (USD$44,000). Both are expected to be launched in 2015 by the Vienna-based Way2Production.

Via Way2Production