NASA is experimenting with 3D printing techniques to develop not one, but at least three different solutions to space instrument manufacturing issues.

The first experiment involves electronics. Those of us on Earth are grateful that our planet’s magnetic field and atmosphere protect us from dangerous space radiation. Not so in orbit or beyond, where NASA craft voyage. The electronic chips inside spacecraft are particularly vulnerable to hits by cosmic rays that can damage or even disable them.

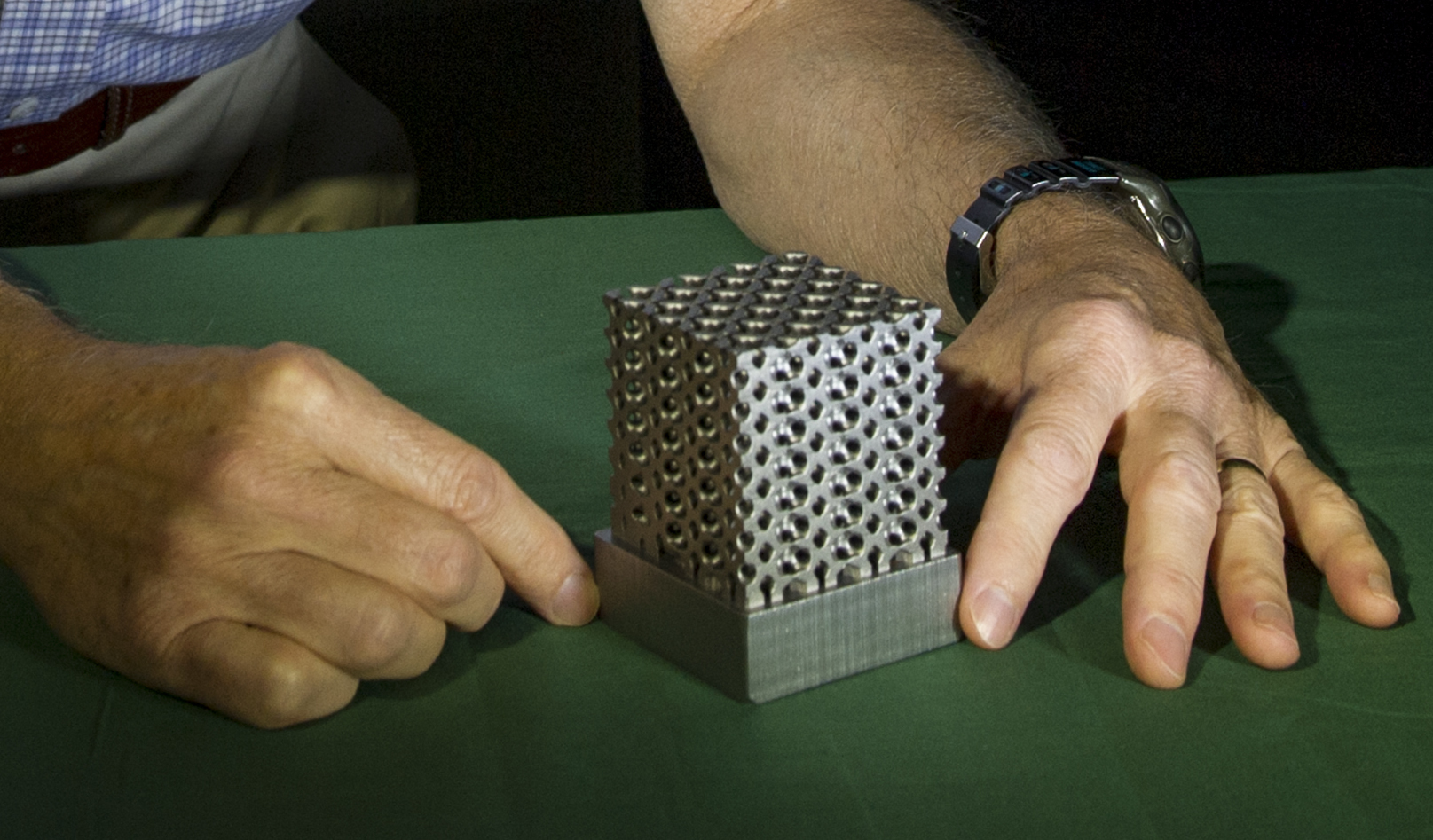

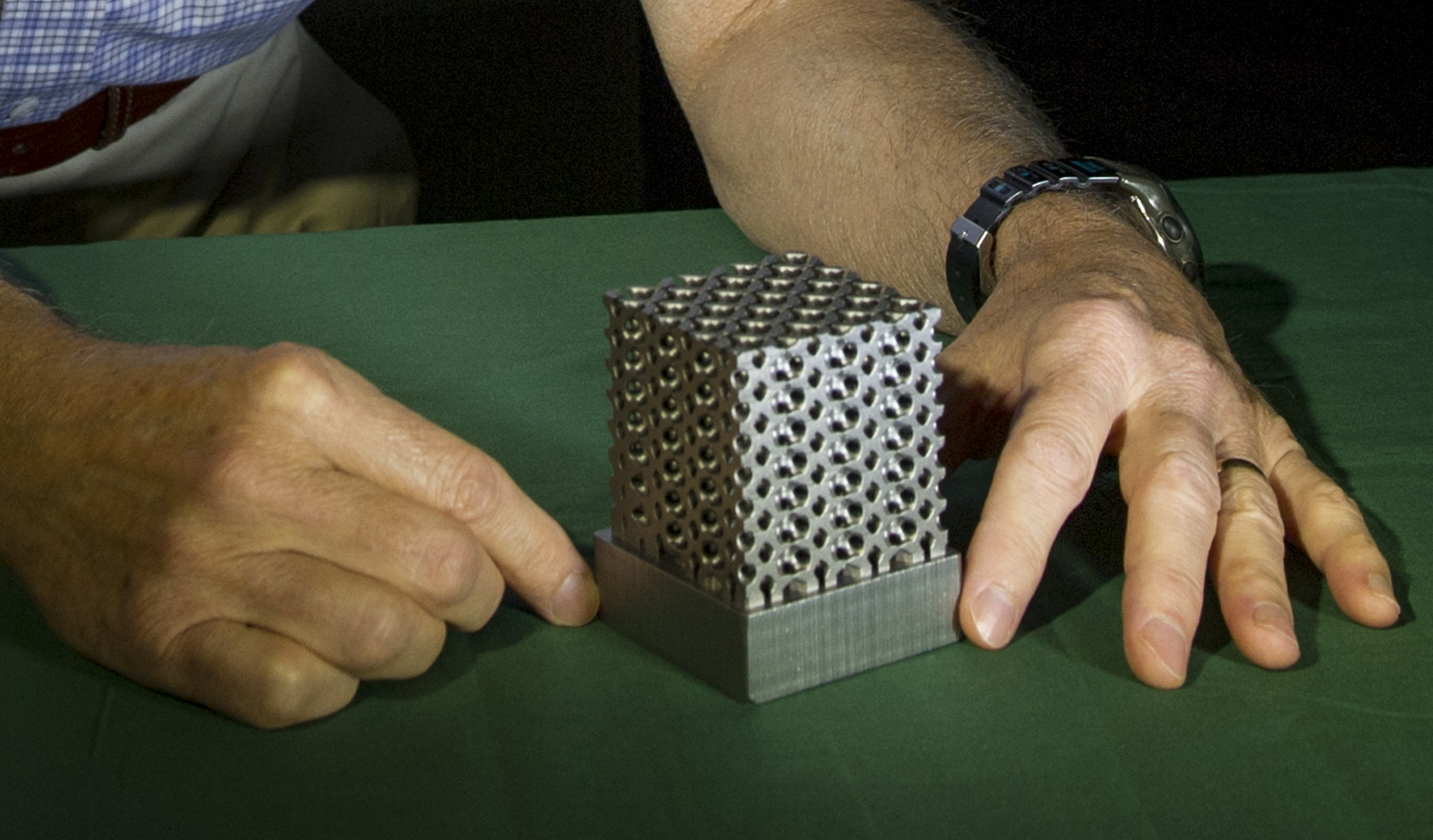

To protect them, NASA has been using metal shielding. However, these conventional solutions are heavy, which is of course bad for spacecraft. The new approach is to 3D print metal shields that custom-fit the chips, providing the same protectiveness with far less mass. They’re quite small, as you can see in this image of NASA Goddard Principal Investigator Jean-Marie Lauenstein holding such a “spot shield”

The second experiment is 3D printing solves a problem of expansion and contraction with varying temperature. Ultra-precise instruments must be rigidly mounted on material that doesn’t expand or contract during the extreme temperature changes in space, lest measurements be invalidated. The new approach is to 3D print “Invar” metal (a nickel-iron alloy that has a ridiculously low coefficient of thermal expansion) using a laser sintering 3D printing technique. Invar mounts will hold precision instruments rigidly in place.

The third experiment is to use direct metal laser sintering to “fabricate proof-of-concept, fully integrated 3-D printed telescopes”. Why? It’s simply faster, lighter and simpler. The complex structures can be printed without any need to break them down into pieces, pieces that require heavy bolts, nuts and lugs to hold it together.

Like many innovations made possible with 3D printing.

Via NASA