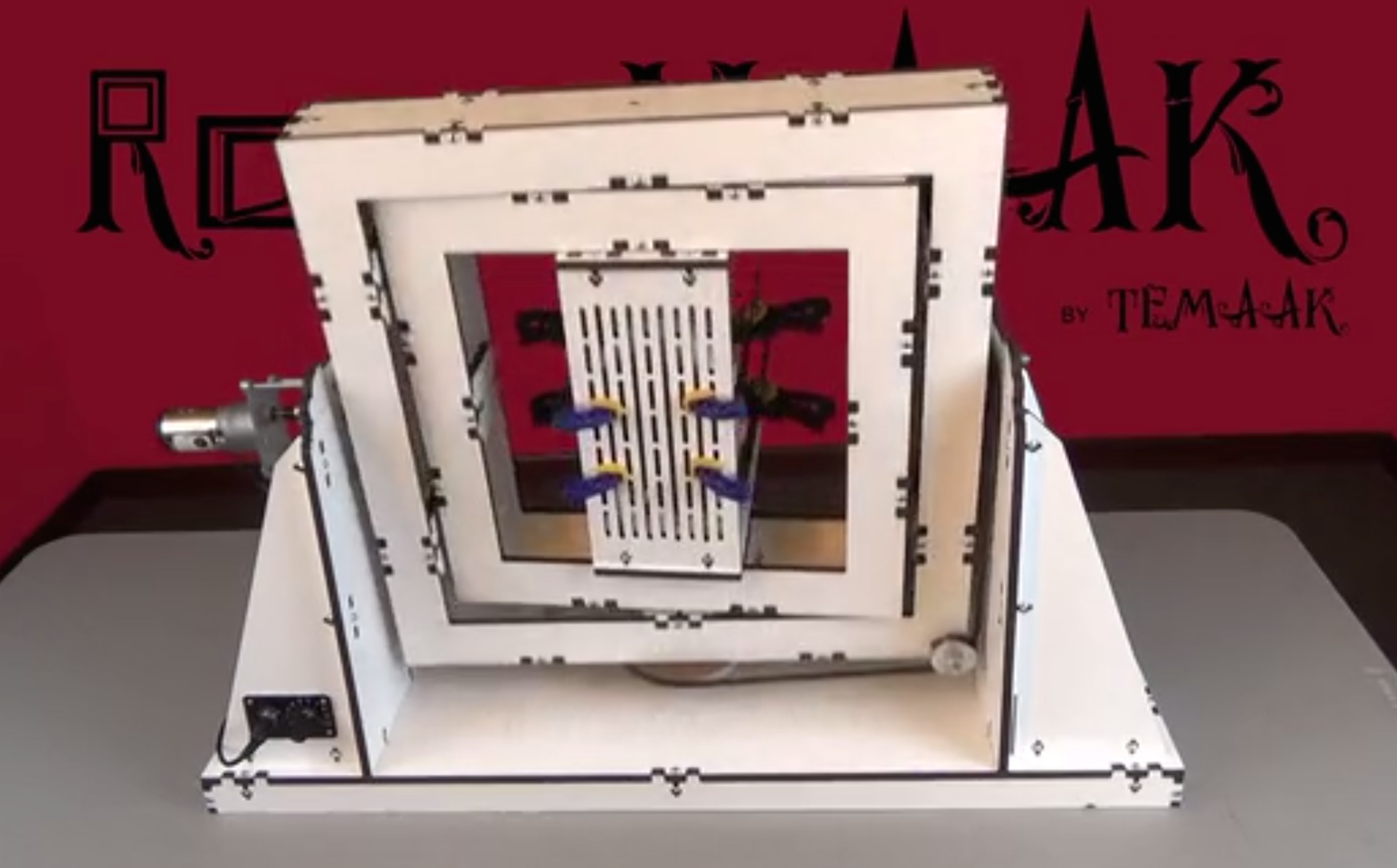

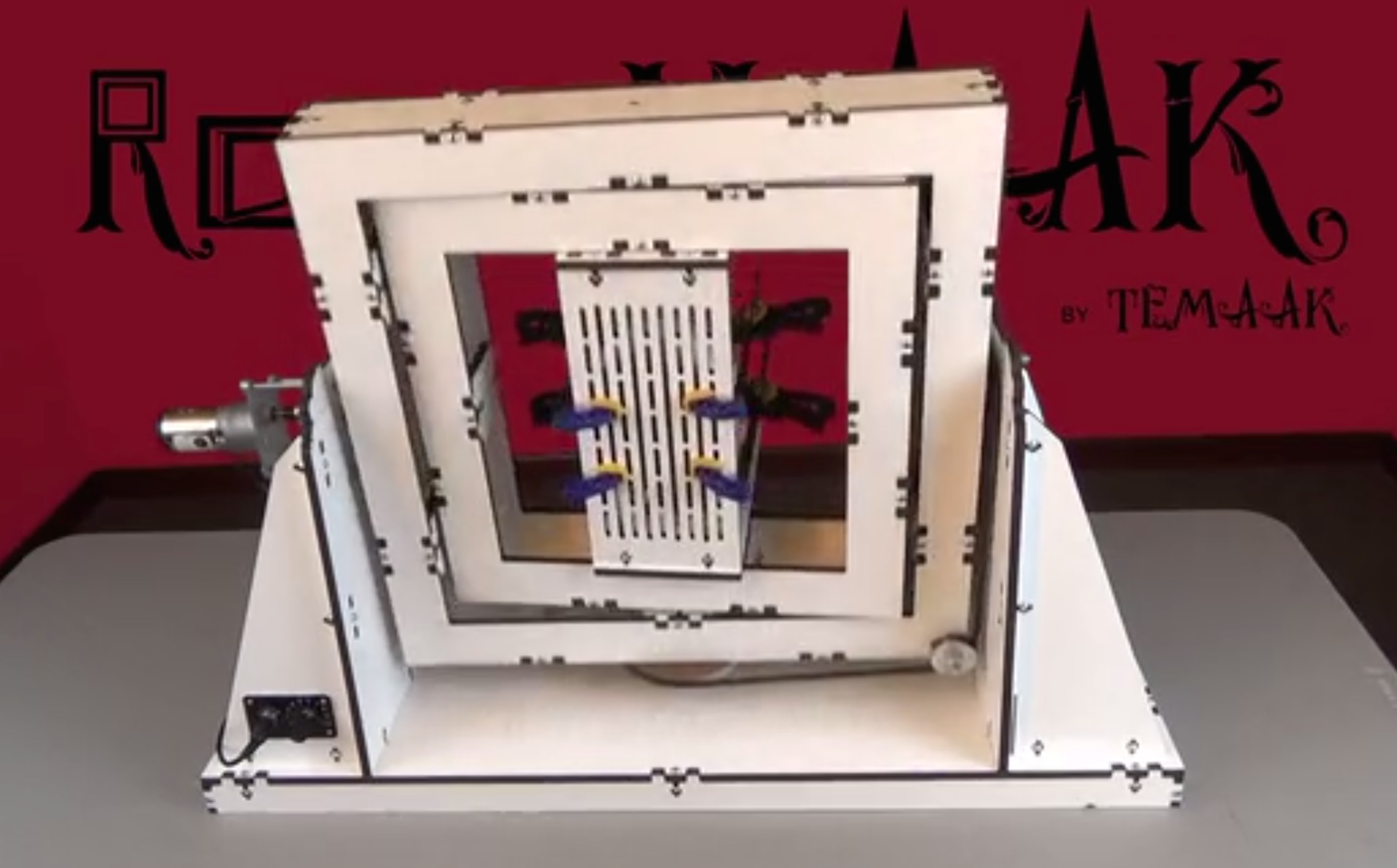

A new Kickstarter project has launched the RotoMAAK, a rotational casting machine. But what does this have to do with 3D printing?

Spin casting, or rotational casting is pretty straightforward: you have a hollow mold filled with a solidifying resin, then spin the mold around every which-way to coat the inner surface of the mold with the resin. When it hardens, remove the object from the mold. You’ve casted a hollow object – normal casting creates solid objects, which in many cases, can waste material.

Mark VanDiepenbos of Indiana invented a desktop spin caster, the RotoMAAK that to us seems to be a logical accessory for personal 3D printing. Here’s how it would work:

- Print an object on your usual 3D printer

- Make a silicone mould of that object – a negative volume

- Pour some liquid resin mixed with a hardener into the mould

- Put the mould in the RotoMAAK and start it up

- Remove the mould after 10 minutes of spinning

- Pull out the newly spin cast object from the mould

Here’s what this means:

You can make copies of your 3D prints in TEN MINUTES.

Of course, this will work only on certain geometries that are mould-friendly, but that still leaves a lot of potential. There are many times when you’d like to make multiple copies of a print but just can’t wait 68 hours for your printer to make them. The RotoMAAK could solve your problem.

It’s a simple device that spins the mould on two axes to ensure complete resin coverage of the inner mould surface. As of this writing, you’ll be able to get one for under USD$700 in kit form. This is very inexpensive for a device that can essentially turn your 3D printing operation into a mini-factory.

Via Kickstarter