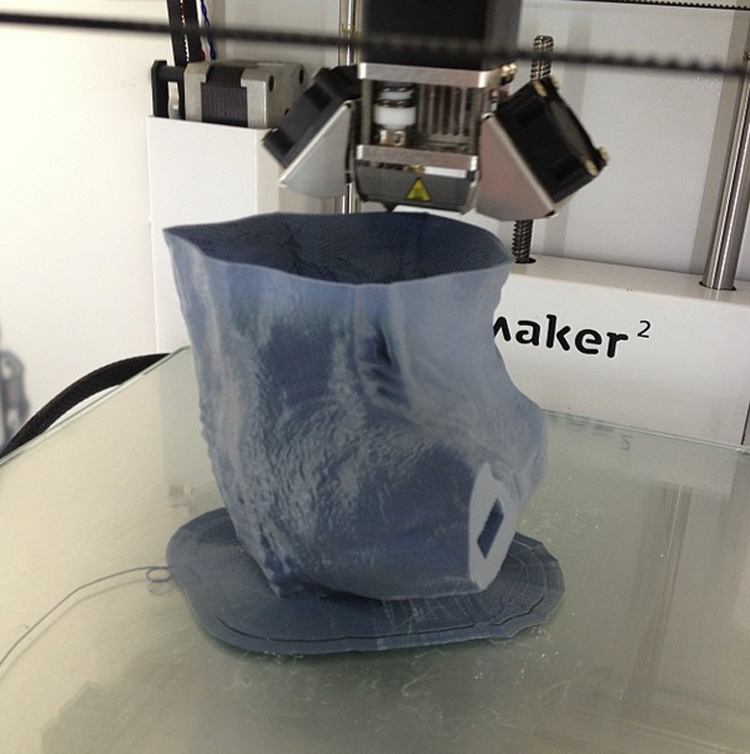

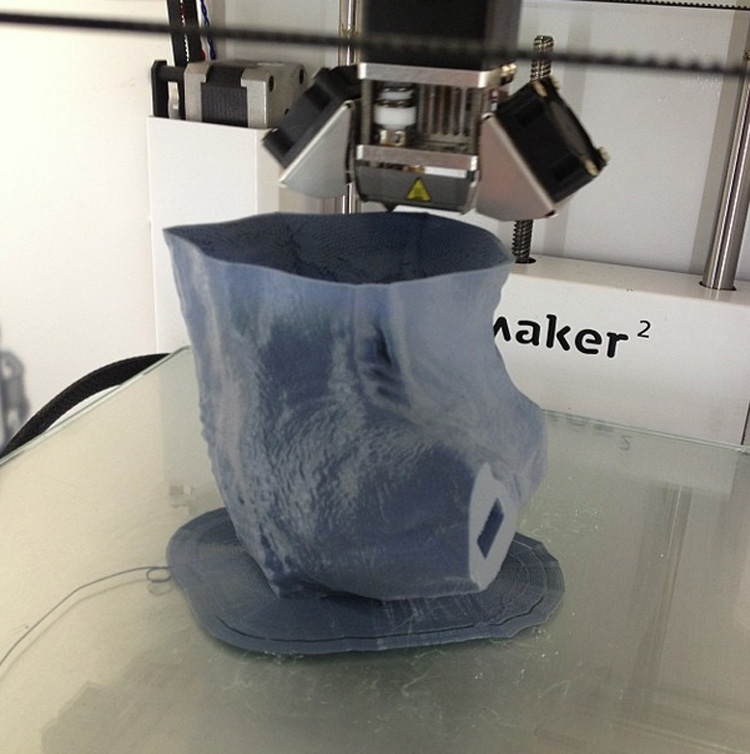

The most spectacular 3D prints are often those that take a significant length of time to print. But how do you ensure the print completes?

Sydney-based VFX artist Paul Braddock has had some experience in producing large, multiple-piece prints on his Ultimaker 2 3D printer. Autodesk’s CG Student Awards recently posted an interview with Braddock, who explained that he 3D prints his ZBrush sculpts with a fine resolution of 0.060mm for as long as 24 hours.

That’s a long time for a personal 3D printer. In our experience, printing can be quite unreliable, and the odds of failure increase the longer you print. While expensive commercial printers can easily print for literally days, that’s not always the case on a personal unit.

Braddock made the observation that many of his failures during long prints were due to under extrusion, where the extruder was pushing out less filament than required. His diagnosis:

To get around my particular issue with under extrusion, I concluded most of the issues came from tension on the material before it enters the feeder. I opted to do away with the stock rear mounted spool holder and printed my own design, it’s a simple A frame type setup that uses a roller with ball bearings for zero friction material feeding. Since doing this, I’ve been able to print consistently for days at a time non stop.

We believe this could be an issue on most personal 3D printers using the filament process, as very few have sophisticated spool holders. Zero-friction spool holders could be a desired accessory for anyone using filament.