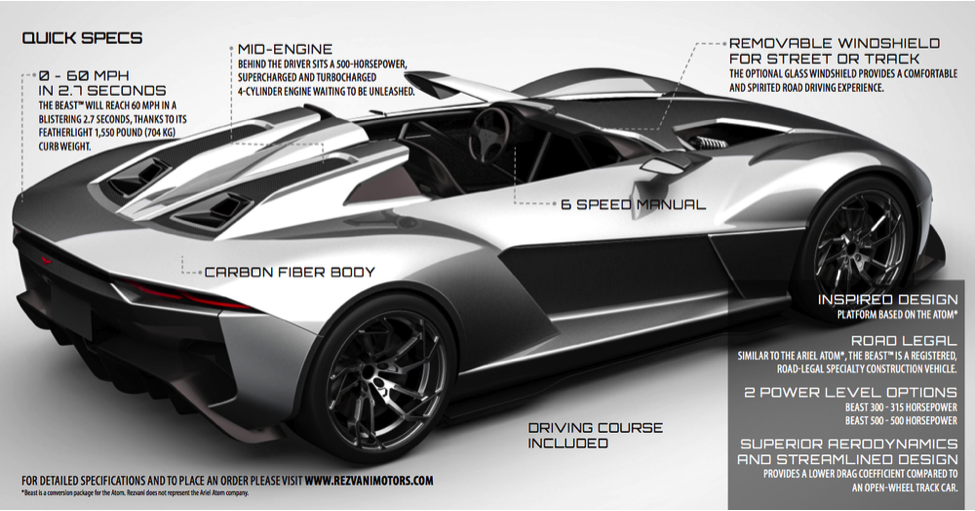

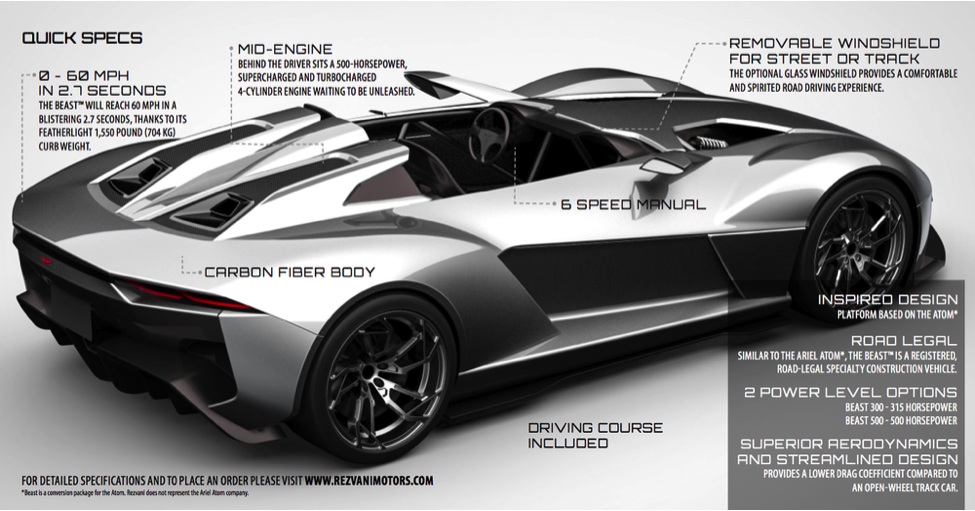

In the past year a good number of car companies began experimenting with 3D printing, wondering how it could help their performance, manufacturing and design. For automotive startup Rezvani Motors 3D printing was key to saving weight in its BEAST 500 supercar.

Built upon the chassis of an Ariel Atom, the BEAST is a 703kg (1,550lb), 500 HP sprite capable of accelerating from 0-100km/h (0-62mph) in 2.7 seconds. Featuring a six-speed manual transmission, Rezvani’s auto leverages a combination of lightweight construction, aerodynamic optimization and advanced construction techniques to create a prototype for the future of automotive manufacturing.

In building the supercar, architect Fardess Rezvani used 3D printing to build the car’s front diffuser, mirrors and lights. In addition to the use of digital manufacturing in the creation of its smaller components, the BEAST’s construction leveraged CNC milling to create its carbon fiber body. According to Rezvani, CNC was used to create an accurate 3D model of the BEAST; from this model engineers fashioned molds for all of the car’s carbon fiber panels, a key element in keeping the BEAST’s weight down.

Read more at ENGINEERING.com