We’re checking out a new product from UK-based OmniDynamics: the Strooder, which converts plastic pellets into 3D printable filament.

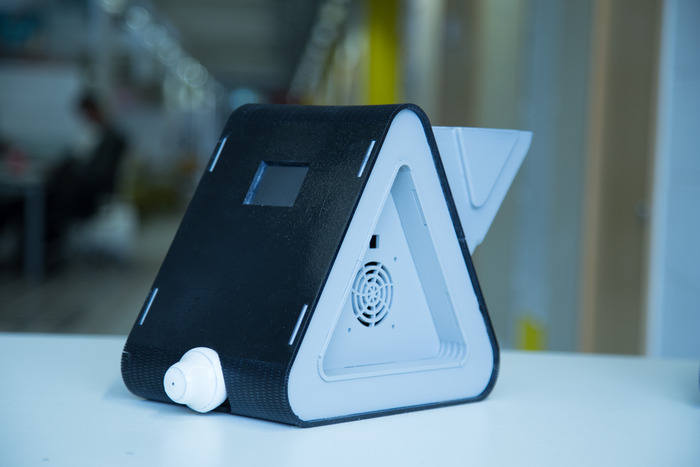

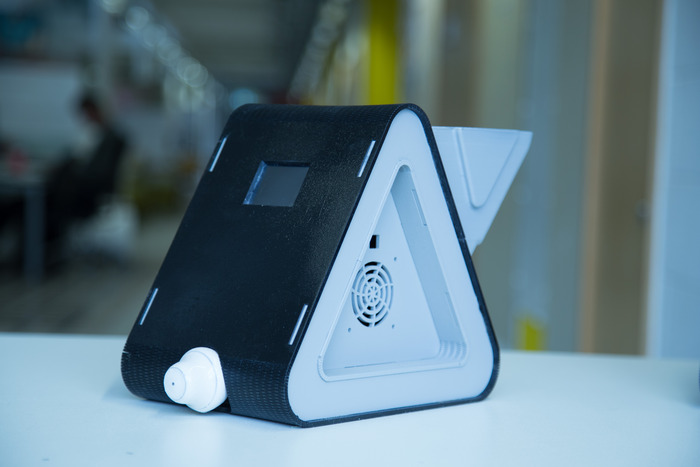

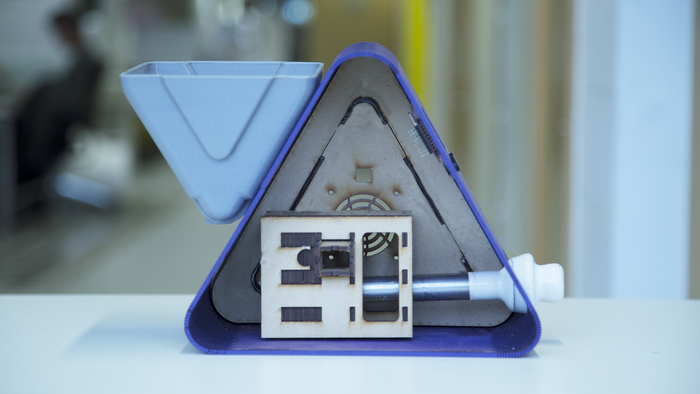

The Strooder’s name is not the only cool aspect; it’s design is very clean, simple and friendly, with a triangular design theme. A small 1L hopper (also triangular) accepts pellets of ABS or PLA, which are then precisely melted and extruded into filament. It’s our understanding they can adapt the machine in the future to accept a wide variety of other material pellets.

Strooder is not the first attempt at a personal filament maker, but there have been very few attempts because filament makers are challenging for several reasons. They must produce very consistent quality filament to be used in 3D printers that, by and large, are quite sensitive to the filament diameter, shape and chemistry. We know of large-scale manufacturers that have had lots of trouble producing good quality filament, even with massive and expensive industrial gear. So to do this in a desktop device is challenging.

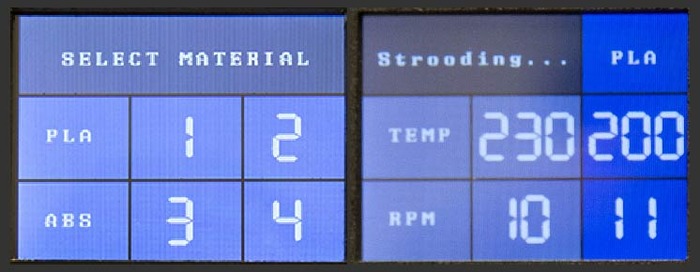

In spite of the challenges, Strooder seems to have done a nice job with the human interface. A handy color control panel clearly shows the system configuration and status. The idea is to pre-set the machine for particular types of plastic to avoid user frustration.

Strooder provides several nozzles that enable the production of 1.75, 2.85 and 3.00mm filaments, all the standard sizes you’ll likely need.

What doesn’t seem to be included is a method of collecting extruded filament. We think this is very important as neatly coiled filament is possible only when it’s right out of the oven.

Via Kickstarter