If you’re using a filament-based personal 3D printer, there’s two major things you must get right to succeed.

Certainly there are lots of things to get right, but we believe Leveling and Z-Gap configuration are the most critical.

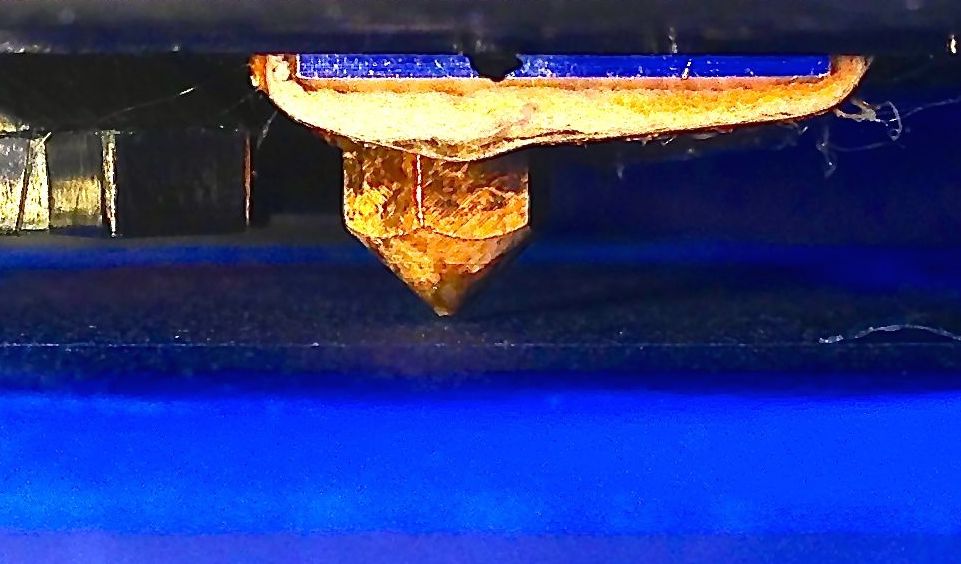

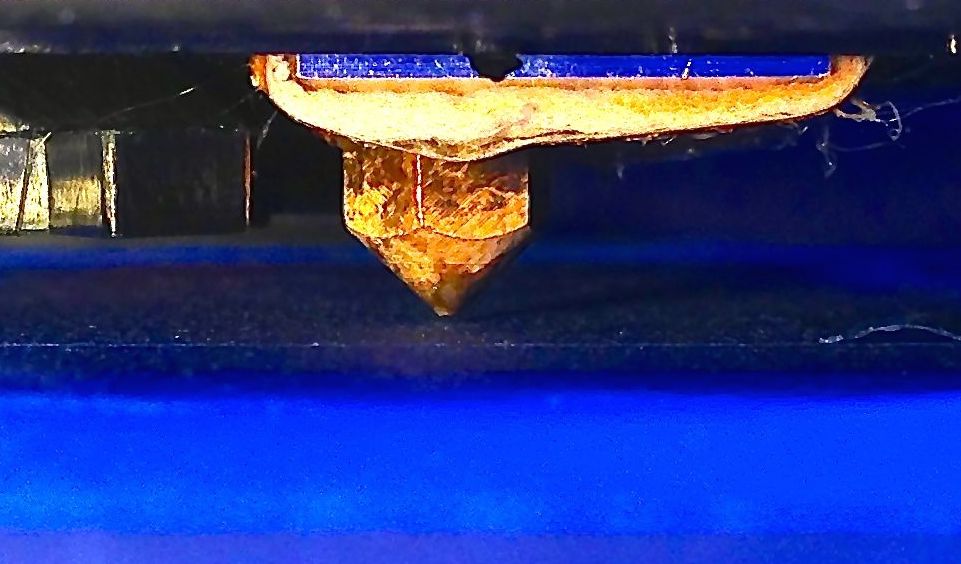

The Z-Gap is the set distance your extruder will be from the print surface when it begins extruding. If the Z-Gap is too big, then the extruded filament will not contact the surface properly and you risk an unstuck print – and failure. If the gap is far too large the extrusion will begin to spin as it falls – you can see this effect if a straight extrusion strand has regular wiggles. On the other hand, a Z-Gap that’s too small also causes problems. The extruded plastic is essentially mushed down to a much wider band than intended. In extreme cases there isn’t sufficient room for the extruded plastic to emerge and backpressure may cause the extruder to slip.

If you don’t have a near-perfectly level print surface, you’re asking for trouble. It means that the Z-Gap will vary depending on which part of the surface is in play. The effects above will occur all over your print bed. That’s definitely not good.

The solutions, fortunately, are straightforward. First level your bed using the manufacturer’s procedure. This could be very easy as some models now include self-leveling or leveling-aids, or even constant-leveled beds. Once leveled, you can set your Z-Gap to the manufacturer’s recommended value.