Startup Orange Maker of California issued a release claiming they’ve invented an entirely new 3D printing process, Heliolithography, which is different from every existing 3D process.

There are few details of the process, but the company says Heliolithography will provide significant benefits:

Orange Maker’s proprietary Heliolithography (HL) printing process displays significant improvements versus conventional Stereolithography (SL), the standard of professional-grade 3D Printers on the market today– by offering greater theoretical limits on printing speed, options for a superior variety of compatible printing materials, smoother surface finishes, and a level of detail not achievable in current desktop printers.

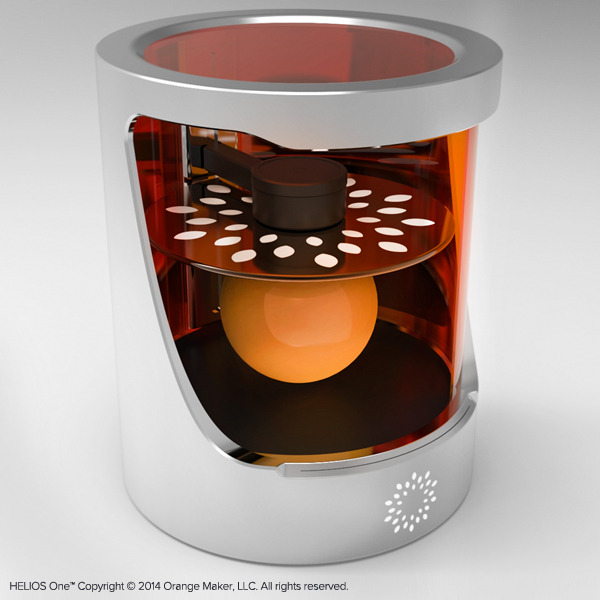

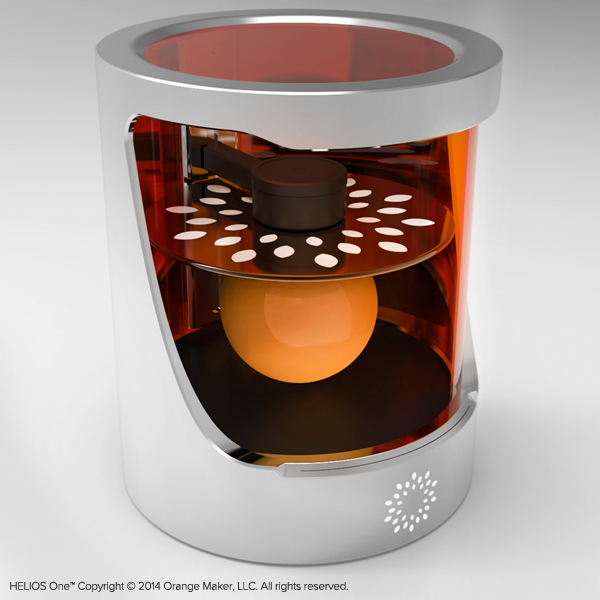

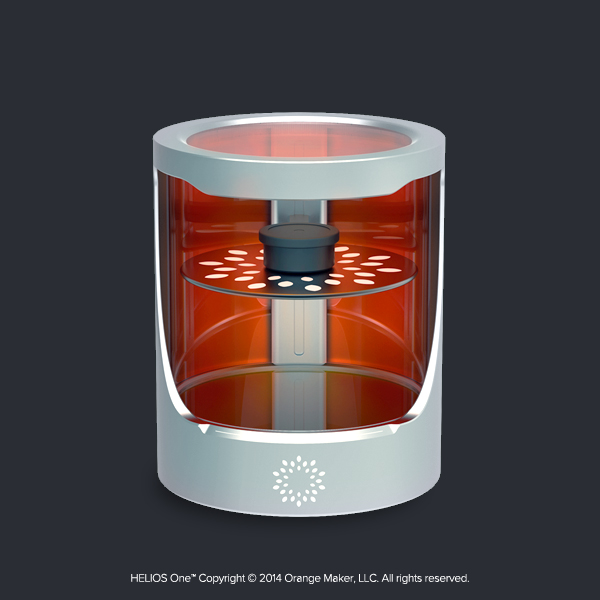

Heliolithography will first make its initial appearance in Orange Maker’s upcoming Helios One 3D printer, pictured above. It’s expected to arrive in 2015, so not soon. There are no publicly available specifications for the machine yet, as we suspect they’re still tuning it to provide the best possible results.

While the Heliolithography process is applicable in both industrial and personal settings, Orange Maker’s first 3D printer is focused on the prosumer market. No pricing for the machine has been released either, but we’re expecting pricing in the USD$3,000 to USD$5,000 range, based on the stated capabilities.

But what exactly is “Heliolithography”? We know that it uses UV-cured liquid resin, but that’s about it. Company representatives we spoke with did not explain any technical details, aside from these:

Helios One directs UV light with ultra-high precision to solidify liquid resin through a ground-breaking curing process.

And:

The HL innovation provides a solution for photopolymer-based 3D printing that solves the adhesion issues that are common in SLA systems.

And:

HL technology represents a major breakthrough in process scalability, allowing the printing process to be carried out from the micro-scale through theoretical size limits greater than current large-scale industrial printers.

So it appears that HL has something to do with how light is deployed to the resin surface. We don’t know if it uses lasers, DLP tech or something else, but based on the Helios One images above, it seems to be a kind of radial light distribution approach. Why does that disc spin in the video above? We don’t know. We’re interested in learning more, but for now Orange Maker is keeping things quiet.

That may be due to their interest in patenting various aspects of the new process, which they’ve apparently spent two years preparing. Their team includes individuals with significant prior experience writing 3D printing in the 1980s, so we suspect they know what they’re doing.

They’ll also know that the original 3D printing patents created in the 1980s by Stratasys and 3D Systems enabled those companies to grow into the giants they are today. Perhaps Orange Maker wishes to do the same with their new process, which they may be able to do, particularly if the technology is applicable to industrial uses as they say.

We’ll be watching carefully.

Via Orange Maker