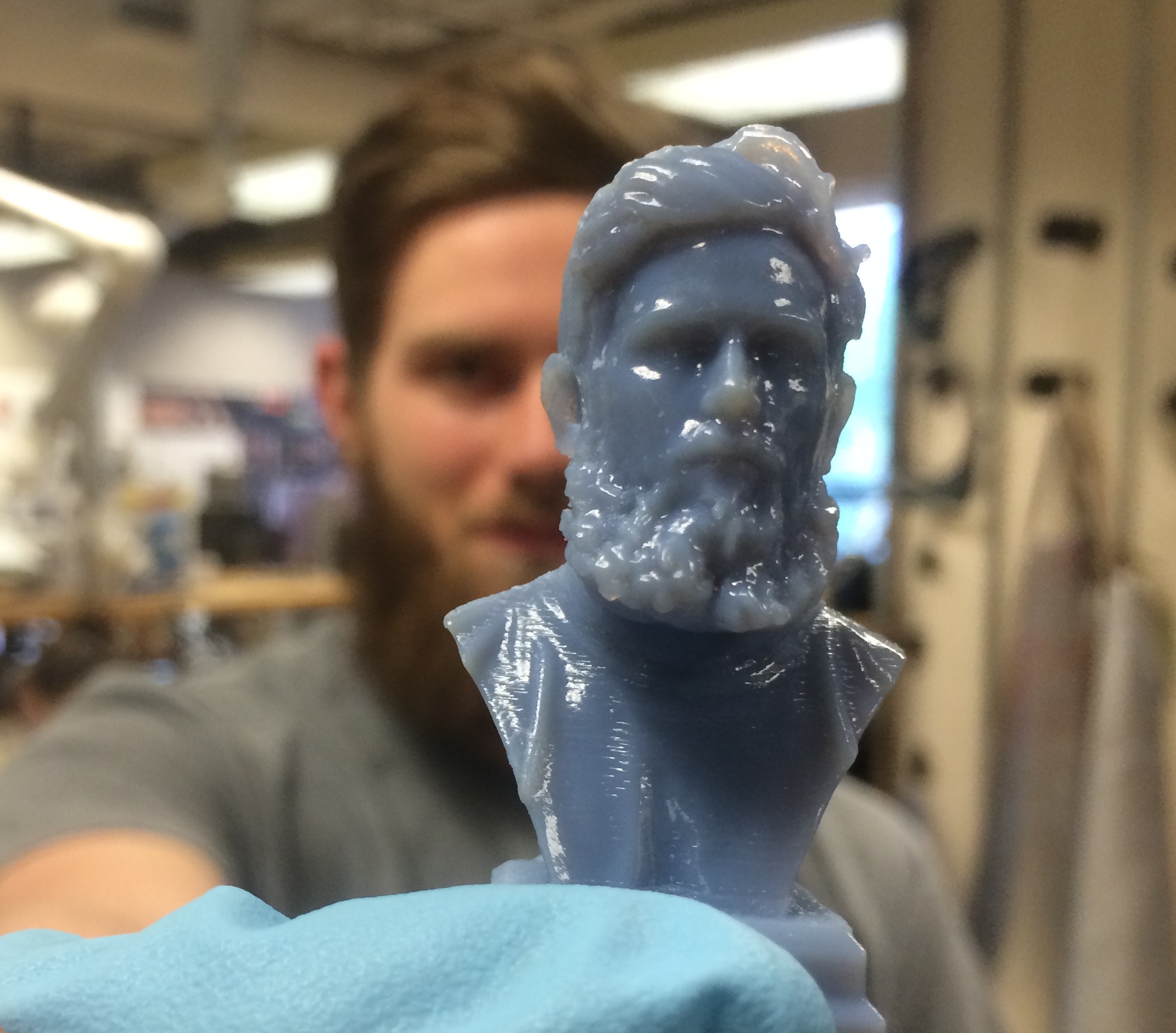

This week’s selection is the Karl Hoenshell bust by none other than Karl Hoenshell himself.

Hoenshell is a student at the Kendall College of Art and Design’s Dow Center for Art, Design, and Technology, taking their Modelmaking and Casting course. The course is intended to train students in the art of lost-wax jewelry-making, but Hoenshell took it a bit farther. His professor, Phil Renato, explains:

For his final ‘multiples’ project he used one of the 3D scanners that we have in our

digital fabrication lab, the Sense, to scan his head. He then refined it into a sculptural bust in Rhino, printed it on our Objet 30 scholar, pulled a rubber mold and injected it with wax, and then cast a series of (50mm) small busts in bronze.

The process of producing the bust may seem straightforward, but not so according to Hoenshell:

One of the main struggles I faced was figuring out weight distribution by just looking at a computer model. After I trimmed the scan to resemble a more traditional “bust” shape I had to put it on something so it would stand on its own. I had to find the right size base so it wouldn’t be too small and not support it, and not too large so it looked goofy when physical. After the base was made it still looked too heavy on one side so I added a support strut in the middle to kind of balance it out and hopefully stand when printed. The support also came in handy later on in the casting process as it made a nice channel to disperse the metal into the cavity.

Another struggle came during the investment process. I happened to place my object too far up in the flask, and placed too much investment in a couple of the waxes I invested. This, later on, caused the mold to blowout when introduced to the vacuum, meaning the mold was useless and could not pour metal into. Luckily I had created a mold of the print so I could inject as many wax replicas as needed.

Lastly the cleanup process of the bronze is proving to be a struggle. The bust is too small to file, as I would lose all of my hair and face, so I’m forced to take it straight to the buffer and buff all the grime and oxidation of the cast away. Under my beard and under the bust are proving to be quite tricky areas to get at with the buff wheel.

We understand additional PLA versions of the bust will be electroplated. Well done!