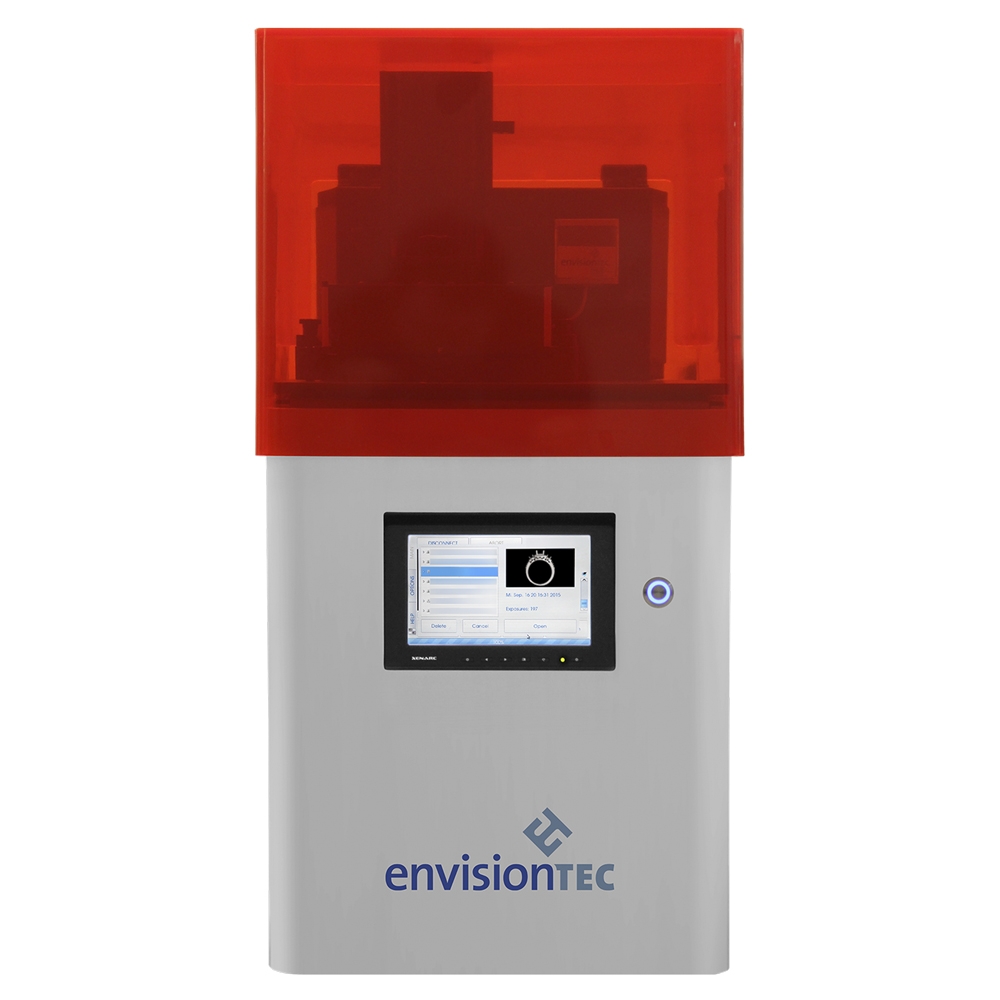

Industrial 3D printer manufacturer EnvisionTEC announced two new 3D printers for their product shelf, the Micro Plus Hi-Res and Micro Plus Advantage.

EnvisionTEC specializes in small-format, but extremely high resolution 3D printers, unlike many other industrial 3D printer manufacturers who focus on large 3D printed parts. EnvisionTEC’s small-volume equipment is typically used for jewelry and medical applications, where the highest resolutions are often required, but not necessarily the largest part volumes. Of course, it’s also possible to print parts for many other domains, too.

While EnvisionTEC has marketed a line of such 3D printers for many years, the new pair of printers provides some interesting workflow advantages.

Both machines feature a new exterior styling, which features a prominent color touch screen for much easier operation. But the important new features are hidden inside the machines.

The onboard computer now includes WiFi capability, an increasingly popular feature on 3D printers. This enables the Micro Plus to be located at any convenient location in a workshop without need for cabling, and provides a way for staff to remotely operate the machine. Of course, you’ll still need to physically visit the machine to load up materials and remove completed prints.

The two machines are slightly different in performance. The Micro Plus Hi-Res has a build volume of 45 x 28 x 100 mm and can provide a resolution of 0.030mm (30 microns) in the X-Y axis.

A word about resolution: while most 3D printers tout Z-axis layer thickness as a specification for resolution, resin-based 3D printers such as EnvisionTEC’s often use X-Y resolution specifications, which are typically unstated for plastic extrusion machines. In other words, the prints are often finer from resin machines because of their ability to increase X-Y resolution as well as Z-axis resolution.

The Micro Plus Advantage has a larger build volume of 60 x 45 x 100 mm, but has a somewhat less fine resolution of 0.060mm (60 microns). As you might have guessed, there is a relationship between build volume and resolution. What’s happening is that the resin projection unit has a fixed number of pixels, and one can obtain finer resolution by focusing the pixels onto a smaller layer area, hence the rule: resolution is proportional to build volume, or at least X-Y resolution.

Both the High-Res and Advantage feature layer sizes of between 0.025 – 0.075mm.

Via EnvisionTEC