You may have heard of Materialise, a Belgian company providing 3D print services. But did you know they operate a number of specialized subsidiaries?

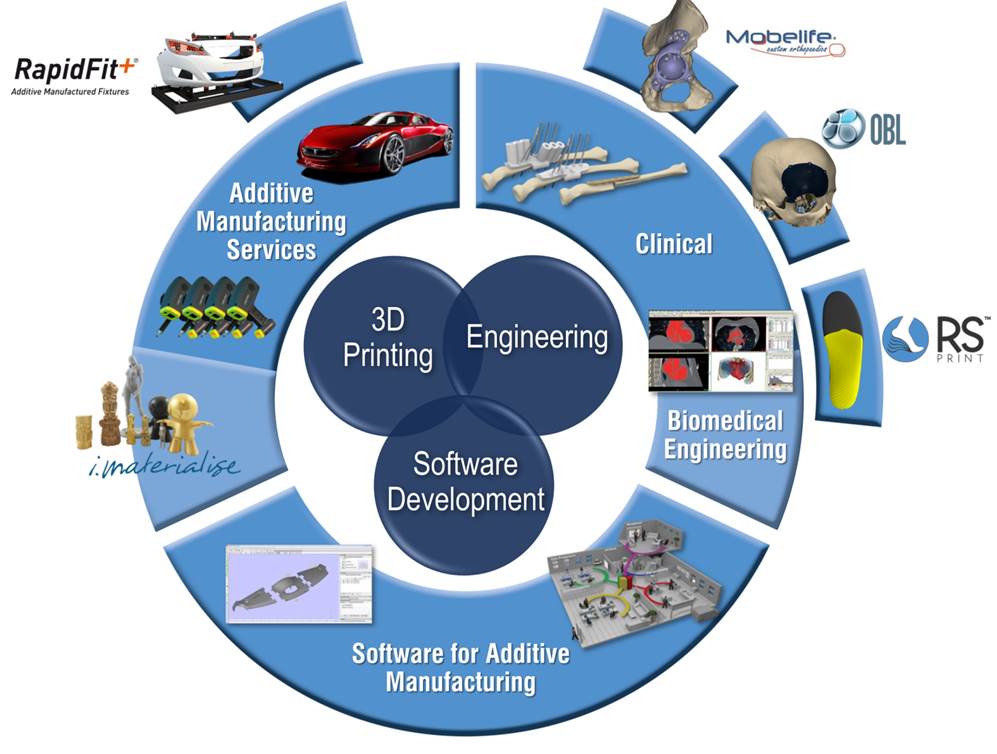

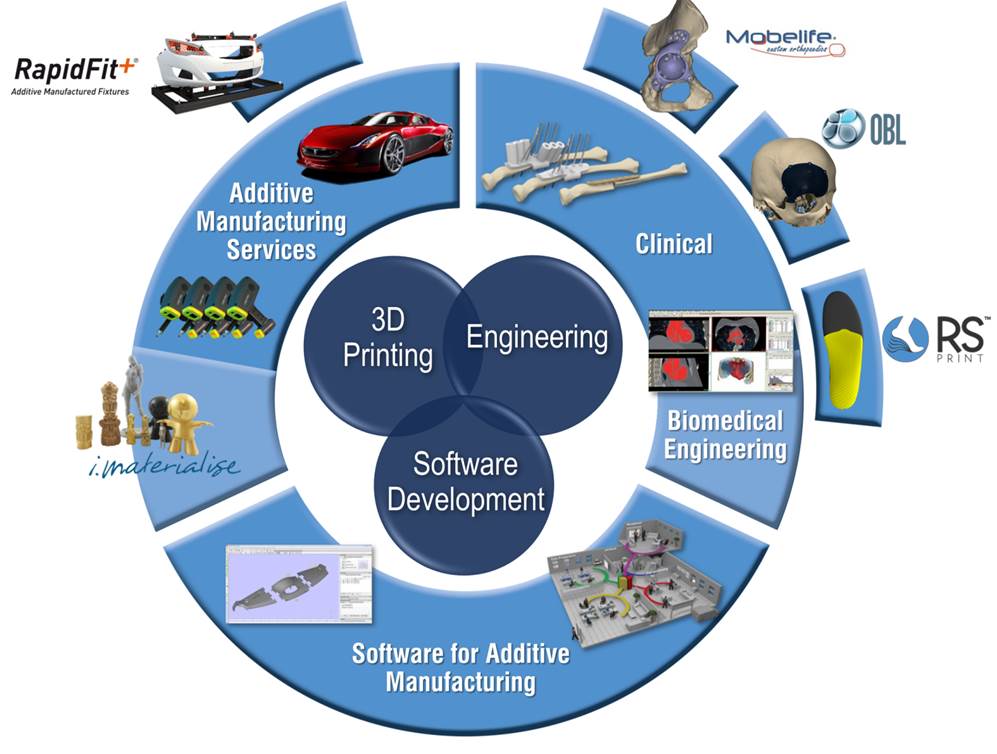

At the core of any company, there’s a key expertise. In the case of Materialise, it’s 3D printing, as you may have guessed. They have provided 3D print services for over 25 years, mainly to industry, but over those decades have gradually expanded into several different focus areas. They’ve organized these subsidiaries as the “Materialise Group”.

The one Materialise subsidiary most frequently mentioned on this blog is i.Materialise, a consumer-focused 3D print service bureau. This service provides comprehensive 3D print capabilities in a variety of materials and machinery and competes directly with other consumer-facing 3D print services such as Shapeways and Sculpteo.

RapidFit “is a smart and revolutionary service offered by Materialise to provide customized jigs, fixtures and quality control solutions by exploiting the benefits of additive manufacturing.” Here Materialise has realized their internal QC practices themselves could become a viable business, which they’ve packaged up and sell under the RapidFit brand.

Mobelife focuses on 3D printed biological implants, such as metal hip replacement products. This is a rapidly growing, but highly specialized market that Materialise can develop using a separate subsidiary. While there are many implant surgeries taking place around the world today, Mobelife can help these surgeries leverage the advantages of 3D print technology.

OBL is a Materialise subsidiary that focuses on custom surgical engineering. This means preparing replacements for arbitrary body parts, such as missing skull fragments. They say this French operation “is a manufacturer of implants for maxillofacial surgery, neurosurgery and plastic surgery”.

RSPrint focuses on 3D printed footwear. This is a rapidly growing area, enabled by recent advances in flexible 3D print materials. Materialise has partnered with RSScan, a leader in foot-scanning technology to enable production of 3D printed insoles.

In addition to the above, Materialise also produces a comprehensive suite of 3D print operational software. Again, most of their products likely began as internal software to solve operational issues, but they’ve decided to productize them and by offering them to the public. Their portfolio includes 3D model repair tools, print preparation software, 3D scan processors, administrative automation and more. They’ve even migrated some tools to the cloud so you can make use of them much more easily.

There’s quite a few players in the 3D print industry these days, and it turns out that Materialise is several of them!

Via Materialise