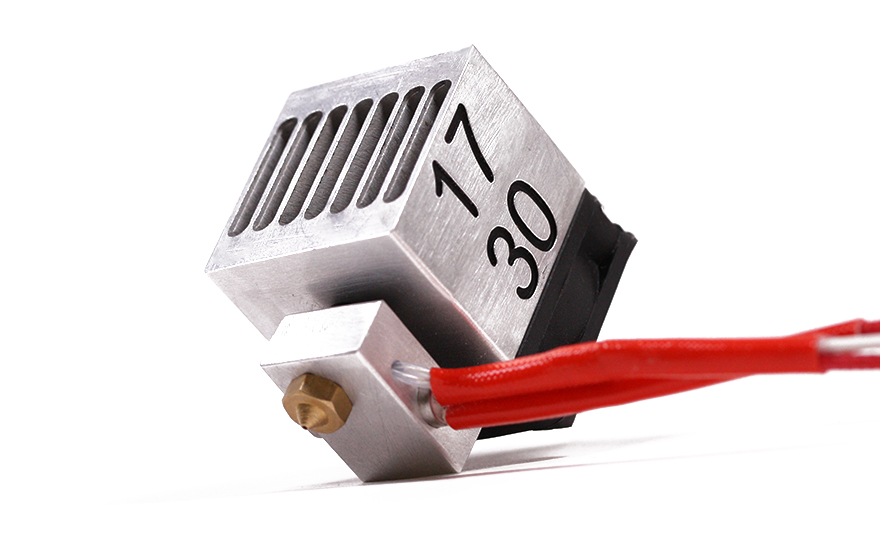

The “1730 Full Metal Hotend” from ReprapUniverse in The Netherlands is able to handle two different filament diameters.

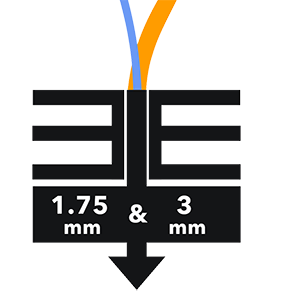

This could solve a problem we have in our lab, and no doubt others do as well: mismatched filament and equipment. While desktop 3D printers initially standardized on 3.00mm (or 2.85mm) filament, after a few years 1.75mm filament emerged and became quite popular. While most new machines employ 1.75mm filament, there are still many that use the larger 3.00mm style.

Hotends on desktop 3D printers must match the filament precisely: 3.00mm filament simply doesn’t fit into channels made for 1.75mm filament, and 1.75mm filament is too loose inside 3.00mm. This extra space is quite problematic as it could permit molten plastic to rise up the tube and freeze in areas where it cannot be heated for removal. This could mean disassembly of the equipment for repair. Not good!

The other problem is the for people with multiple 3D printers, you may end up with supplies of both 1.75mm and 3.00mm filament that can only be used on machines with that diameter of hotend.

The new approach from ReprapUniverse, who designed the 1730 Hotend with materials wizard Kai Parthy, enables use of both diameters! The new hotend accomplishes this feat by offering modular nozzles that can be quickly swapped out: for example, you can take out the 3.00mm nozzle and swap in the 1.75mm nozzle in “less than 5 minutes”.

While other machines do offer similar nozzle switching, their purpose is to change the diameter of the extrusion, not the diameter of the input filament. The 1730 Hotend also can change extrusion diameter too, as the product is available in “multiple nozzle diameters”.

The 1730 hotend is compatible with both direct and borden-style extruders, and is also capable of higher temperatures, meaning it is able to extrude more exotic materials. In fact, they say they’re working on an incredibly hot +500C “expert module add on” for the future.

Design of such a hotend is complex, as it requires considerable ingenuity in separating the hot and cool zones of the hot end in order to minimize the channel length dedicated to a specific diameter. Basically, they’ve created a hotend that has a short-short hot zone that’s modular. This could also significantly improve retraction performance, which they say it does.

Can you buy one? Unfortunately, not yet. The company plans to launch the product on a Kickstarter campaign sometime in mid-January. At that time we’ll find out the pricing for this interesting piece of 3D printing hardware.

One more thing: with a modular hotend, it could now be possible to provide an option to handle filament diameters other than just 1.75mm and 3.00mm. Our suggestion: DO NOT DO THIS! We already have enough “standard” filament sizes and don’t require any more confusion in the industry.

Via 1730Hotend