Researchers at MIT have developed “Fab Forms”, a system that pre-tests thousands of variations of a 3D model to simplify end user design.

The problem being solved by the MIT team is that of turnaround time during 3D model development. Typically a 3D model is created in CAD software, and then it is tested for strength, stability and other engineering aspects. While the CAD design can take considerable time, the testing can also be quite time consuming, during which the designer is idle. The testing typically involves significant mathematical processing to simulate physical effects.

The MIT Fab Forms system essentially eliminates this bottleneck by pre-calculating all the test results. Here’s how it works:

- A CAD model of something is created in the usual manner.

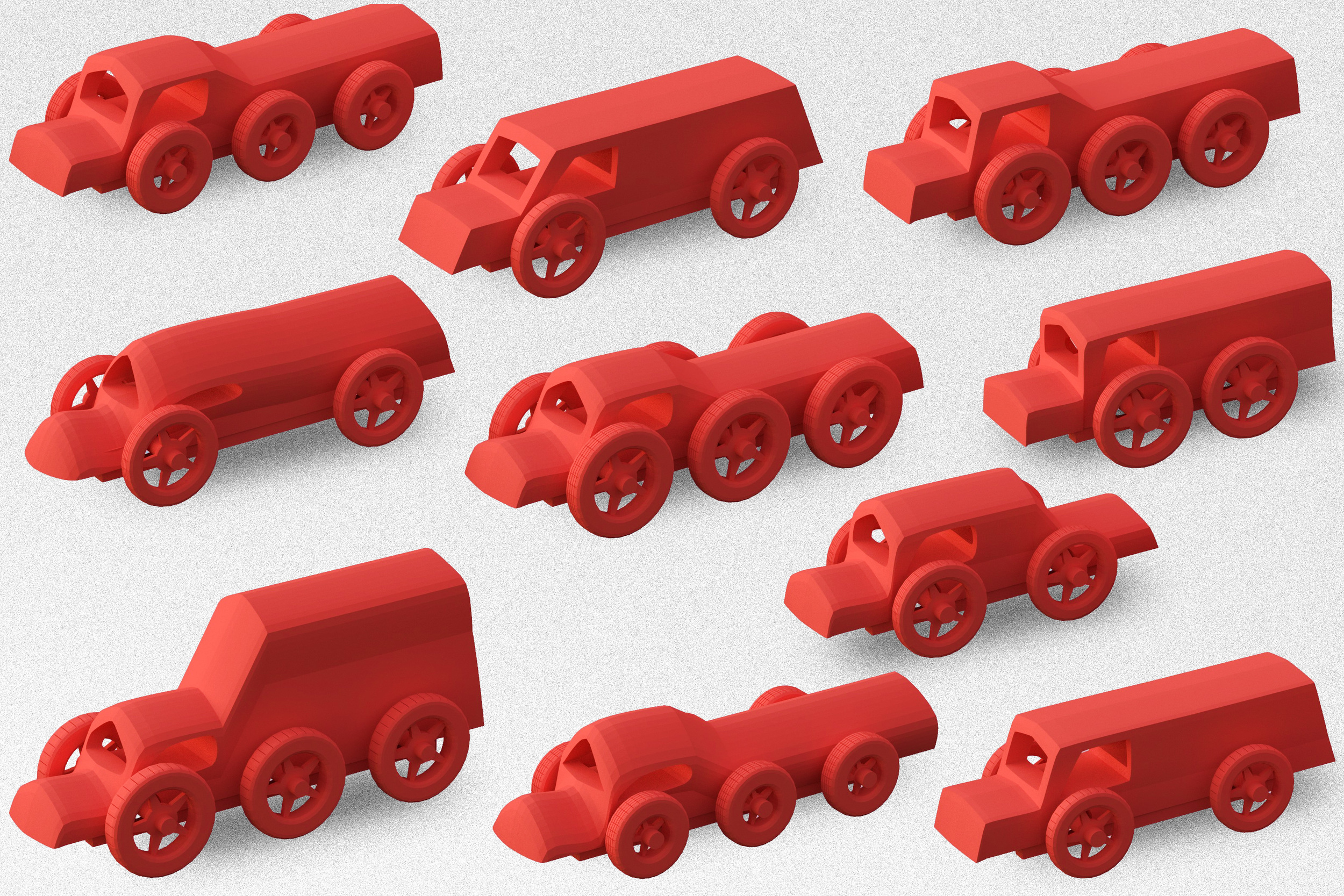

- Fab Forms then develops variations of the original 3D model by tweaking the numerical parameters used to create the design. This can produce up to “hundreds of thousands” of variations.

- A cloud-based network of high-performance machines prepares tests for ALL the variations, consuming huge amounts of processing time.

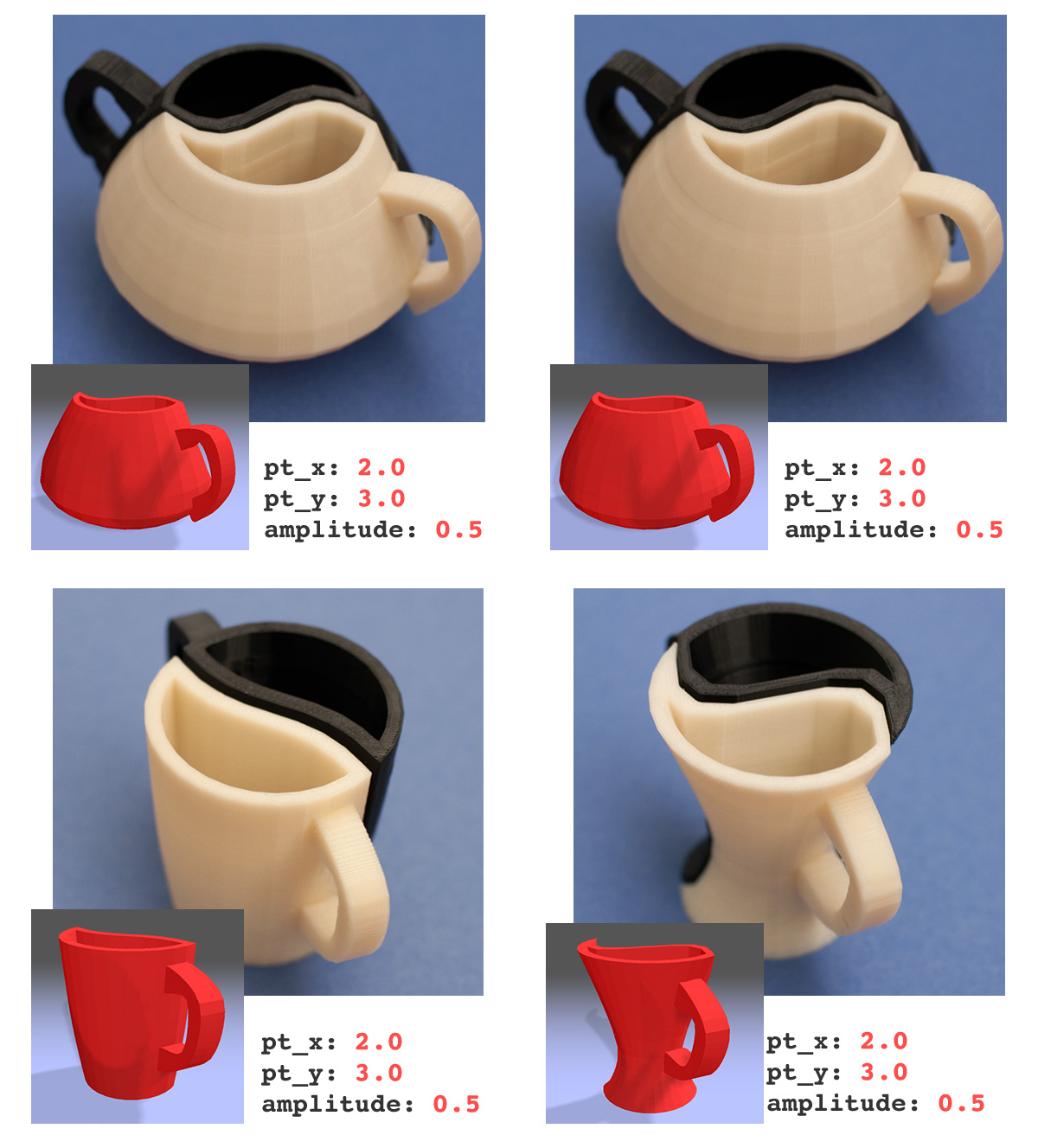

- Fab Forms then presents the massive database of variations and test results to a user, who needs only to tickle some parameter slider bars to browse through the database – as if they were regenerating the model each time, but really they’re just calling up the pre-calculated results.

Here you can see four variations of a single 3D model; note the “diversity” of the results.

This system enables a less-than knowledgable user to “operate” a pre-made 3D design to find the variation that best fits the required engineering scenario, in a kind of tag-team arrangement.

While this approach can definitely speed the search for optimum variations, it does have a drawback: it only works on a set 3D model. You can’t easily change the original 3D model without regenerating all the test cases in a time-consuming slurp of processing power.

No doubt this approach will be quite useful in some design situations, so we expect it to be commercialized in some manner in the future.

Via MIT (Hat tip to Will)