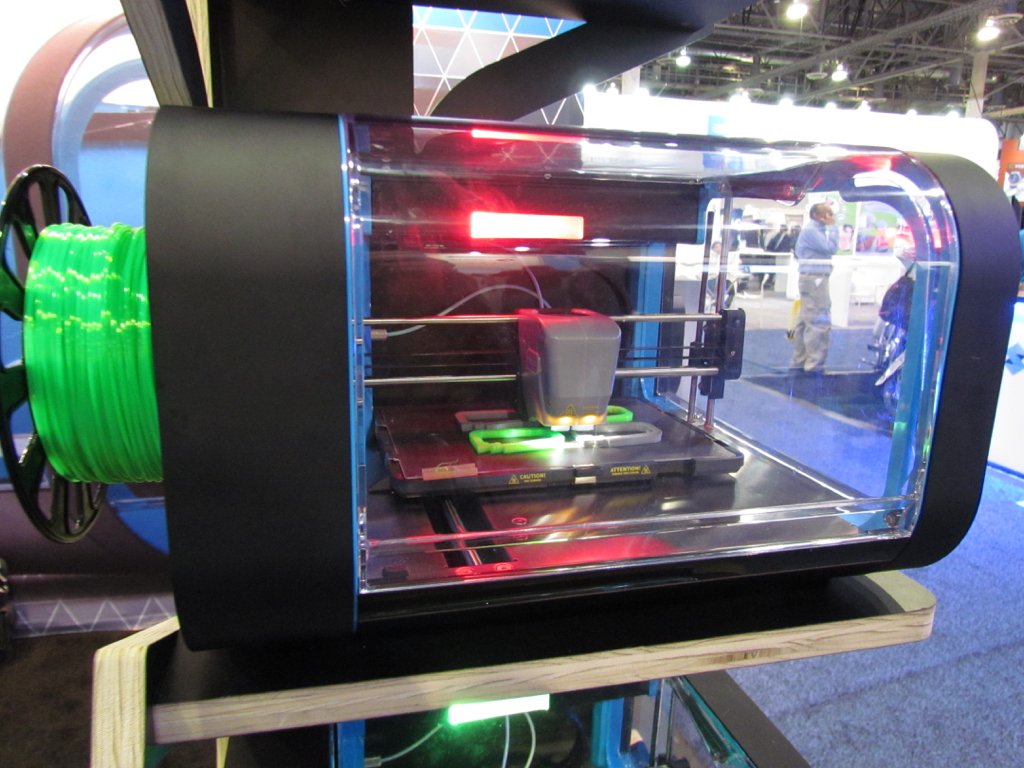

CEL Robox makes a very decent desktop 3D printer, but we asked them what they’ve been up to. The answer: materials!

It’s not surprising there hasn’t been too many changes to the Robox 3D printer, as it already includes many very useful features for ease of use and safety. Here’s only a few items from their very long list of highly interesting features:

- Enclosed chamber for reliable 3D printing of any materials

- “Pop off” build surface for easy print removal that requires no surface treatments

- Two-year warranty

- Quick-swap toolhead for future additional functions beyond 3D printing

- Smart recognition of plastic filament using their “SmartReel” approach

- Automatic filament loading and fault detection/pausing/alerting

- Very rapid build plate heating (e.g. up to +130C in less than 3 minutes!)

- Auto-locking door during print operations

- Automated bed leveling on each print

- Custom-built software to drive the Robox that provides an incredibly simple interface

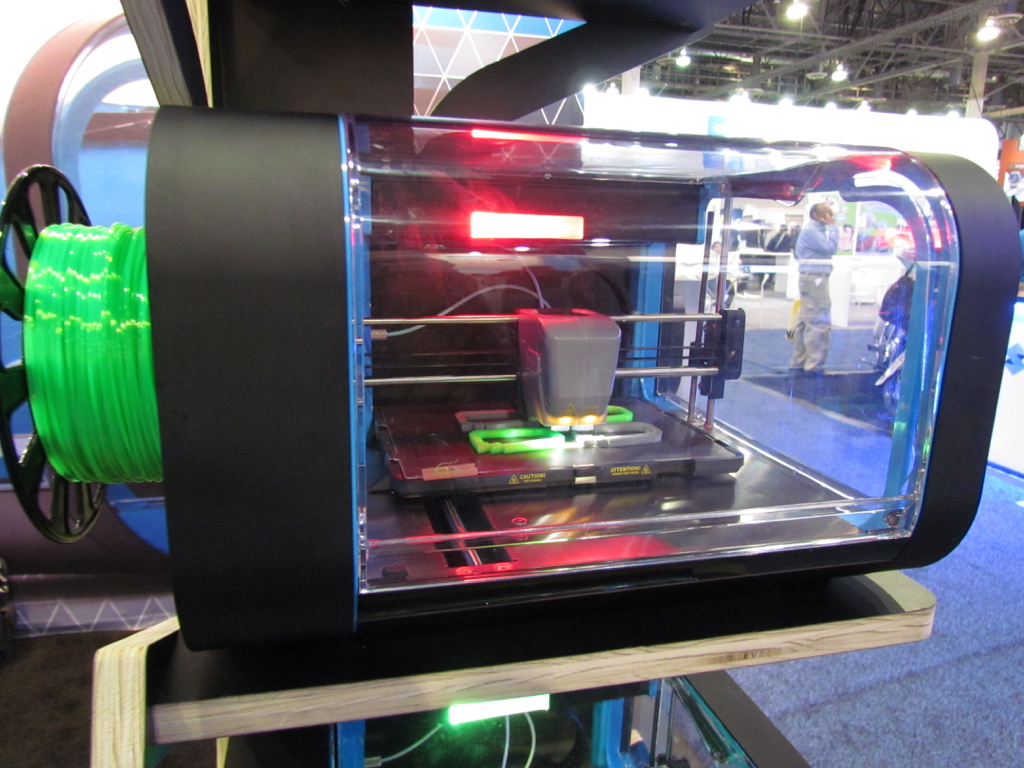

One recent hardware upgrade they’ve developed is a way to use flexible filaments in their machine. They’ve upgraded the extruder to permit use of flexible filaments in a borden-style system, which we haven’t yet seen in other machines.

Here we see an example print using flexible material. It’s a hand that includes some rigid and flexible components. They’ve installed some filament that’s used to pull the fingers closed, but otherwise the hand is printed in a single operation.

So with all these features, what are they doing now? Evidently the company is working closely with manufacturers of various plastic filaments to ensure the Robox can be tuned to use them most effectively.

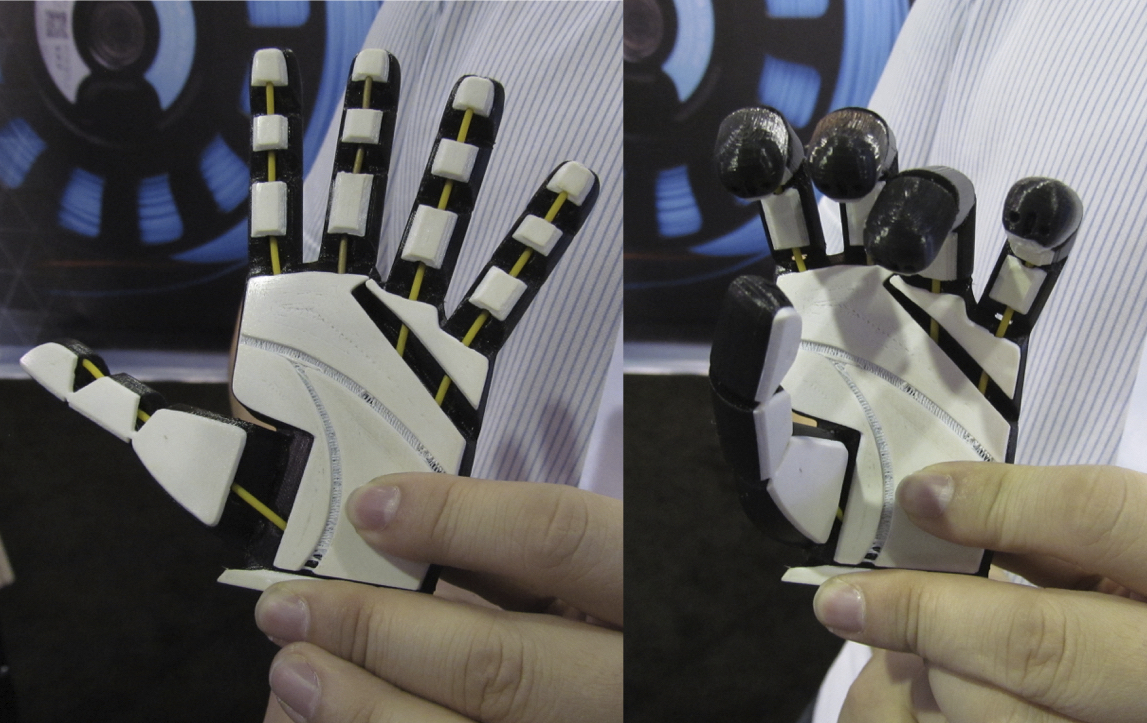

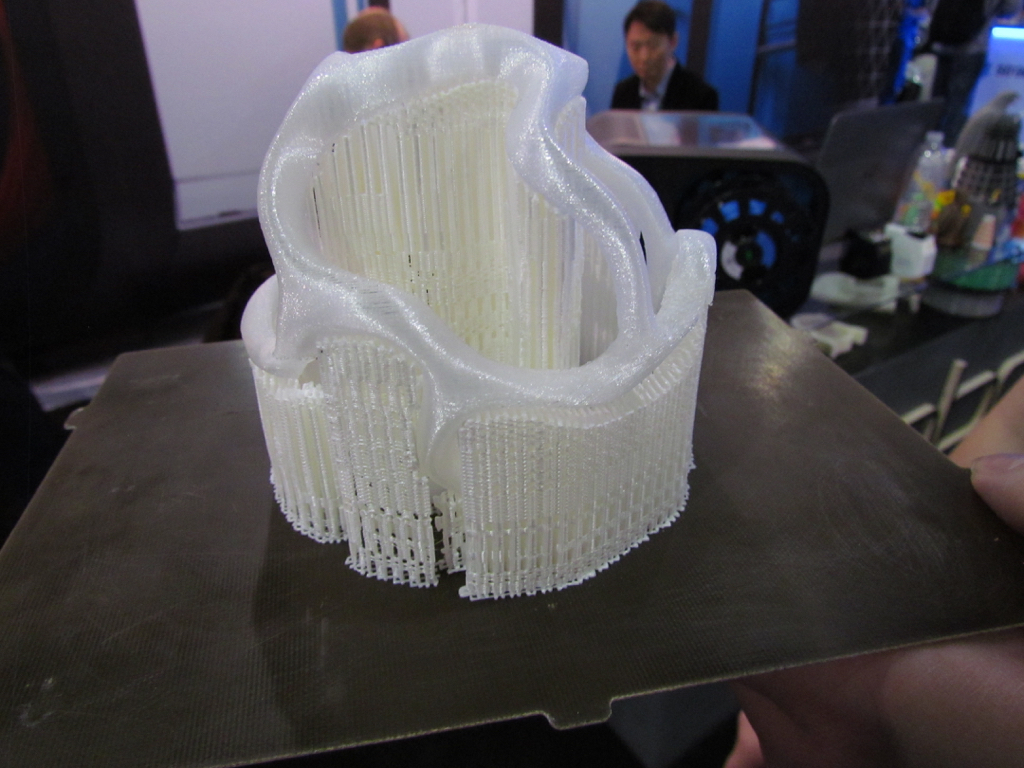

One example shown here is a print using Polymaker’s support material, which we were told is exceptionally easy to remove. Another material they’ve been testing is Polymaker’s PolyWood, which uses a foaming agent to simulate wood properties, without actually including any real wood particles – which often clog nozzles.

They’re also working on polycarbonate filament, which they say is a first for desktop 3D printers.

It seems that the Robox could be a very good choice if you’re looking for a quality desktop 3D printer that’s loaded with reliability features. You can pick one up for only USD$1,499 for the single extruder version, and USD$1,799 for the dual configuration.

Via CEL Robox