A new extruder design has hit Kickstarter: the Zesty Nimble.

The Zesty Nimble is a product of startup Zesty, who happen to be designing a 3D printer of their own, but in the interim have decided to release part of their new design: the extruder.

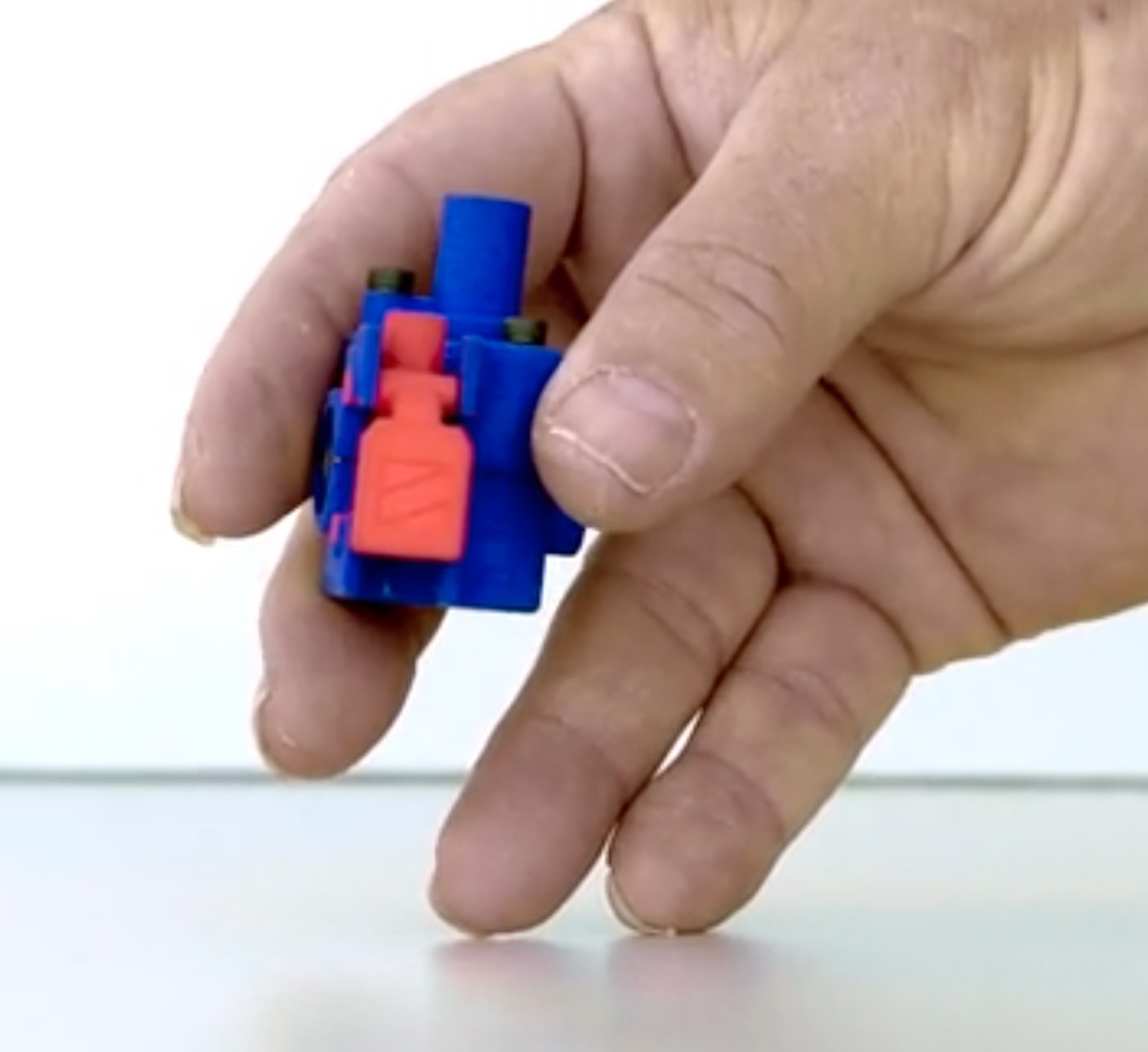

The Nimble is aptly named as it weighs only 33g, and thus carries far less momentum when being abruptly moved about by a 3D printer’s motion system. This is far less than typical extruders that are in the 200g range if using standard parts.

The light weight of this design allows a 3D printer to move faster, because changes in motion direction are easier to handle. Heavy units have to operate slower because they cannot overcome the momentum if direction is suddenly changed.

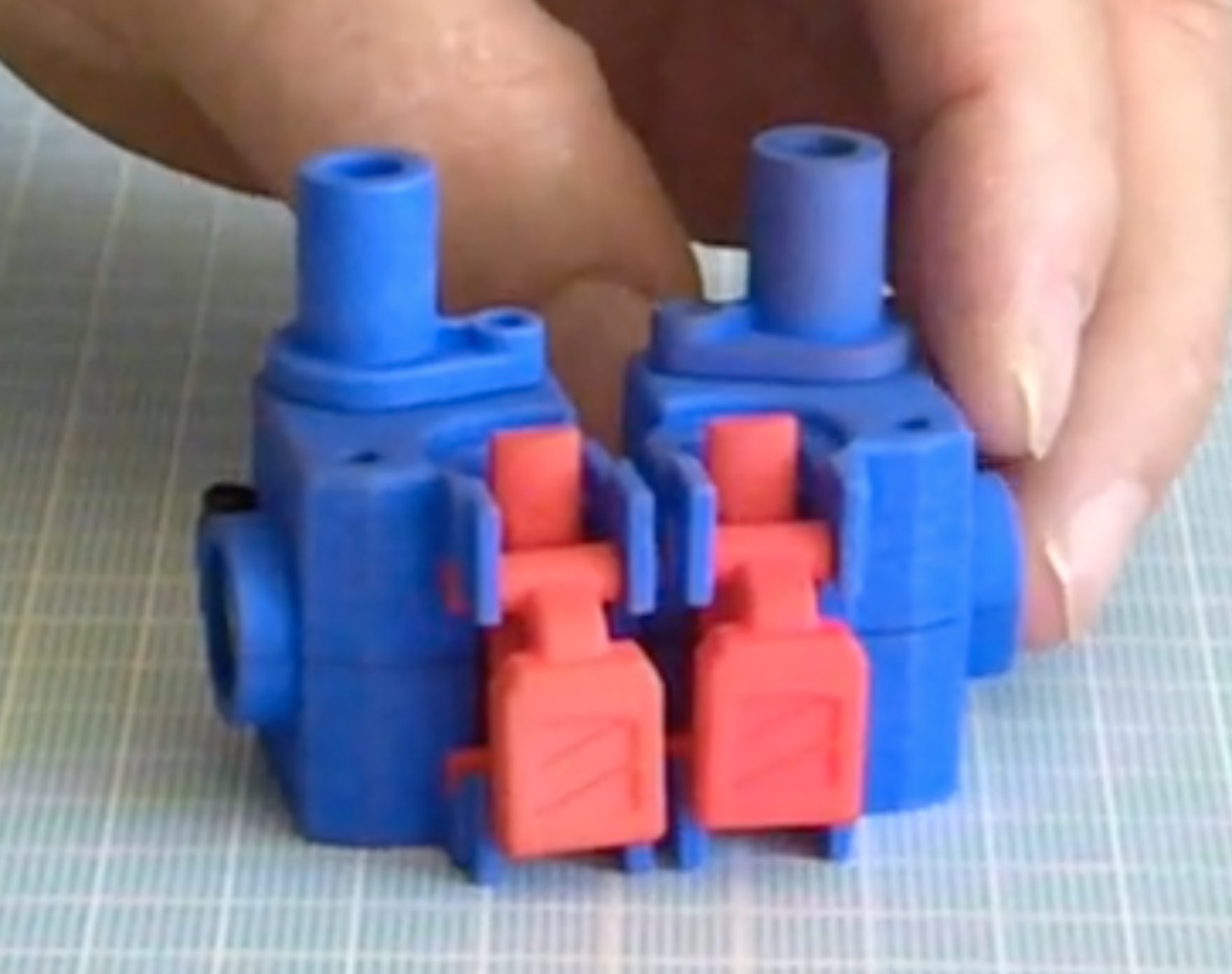

The Nimble is designed to clamp onto standard layouts found in many 3D printer designs, meaning you can, if you have the right kind of 3D printer, swap one in. And on some units, you might even be able to handle two Nimbles due to its small physical size.

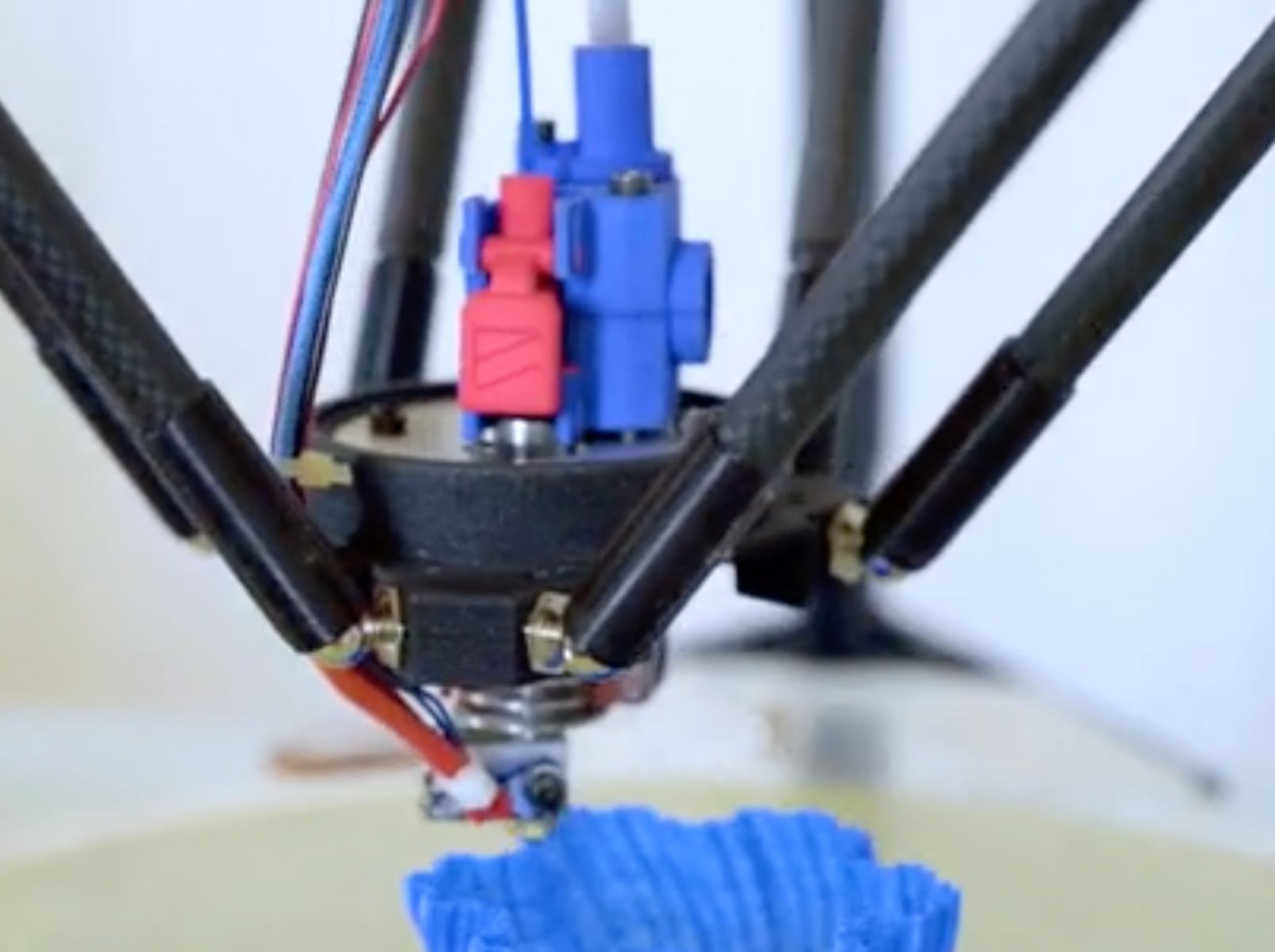

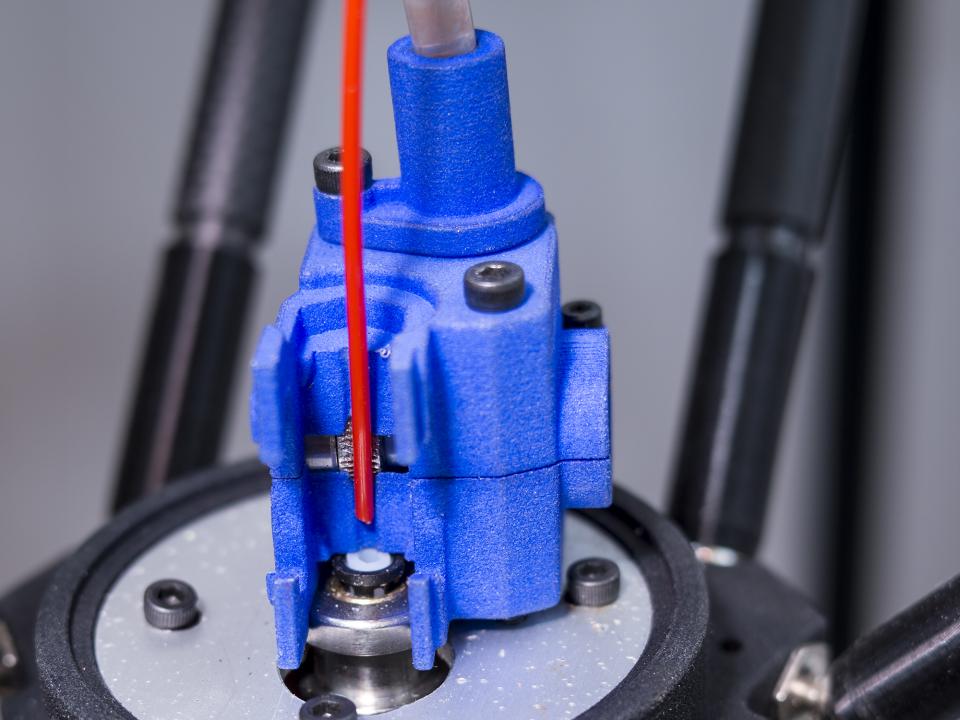

Where this unit could be of most benefit is within delta-style 3D printers. Such machines invariably use the Bowden extrusion concept, where the extrusion motor is distantly separated from the hot end to avoid weight on the moving parts.

While the Bowden approach satisfies weight requirements, it has challenges handling thinner or flexible filaments, which can bunch up during the long traverse from motor to hot end. As a result, delta-style 3D printers don’t often attempt printing flexible filaments.

However, the Nimble is not a Bowden design, but is a Direct drive, where the motor is very close to the hot end. Flexible filaments are no problem!

The light weight of the Nimble makes it an ideal replacement system for delta-style 3D printers.

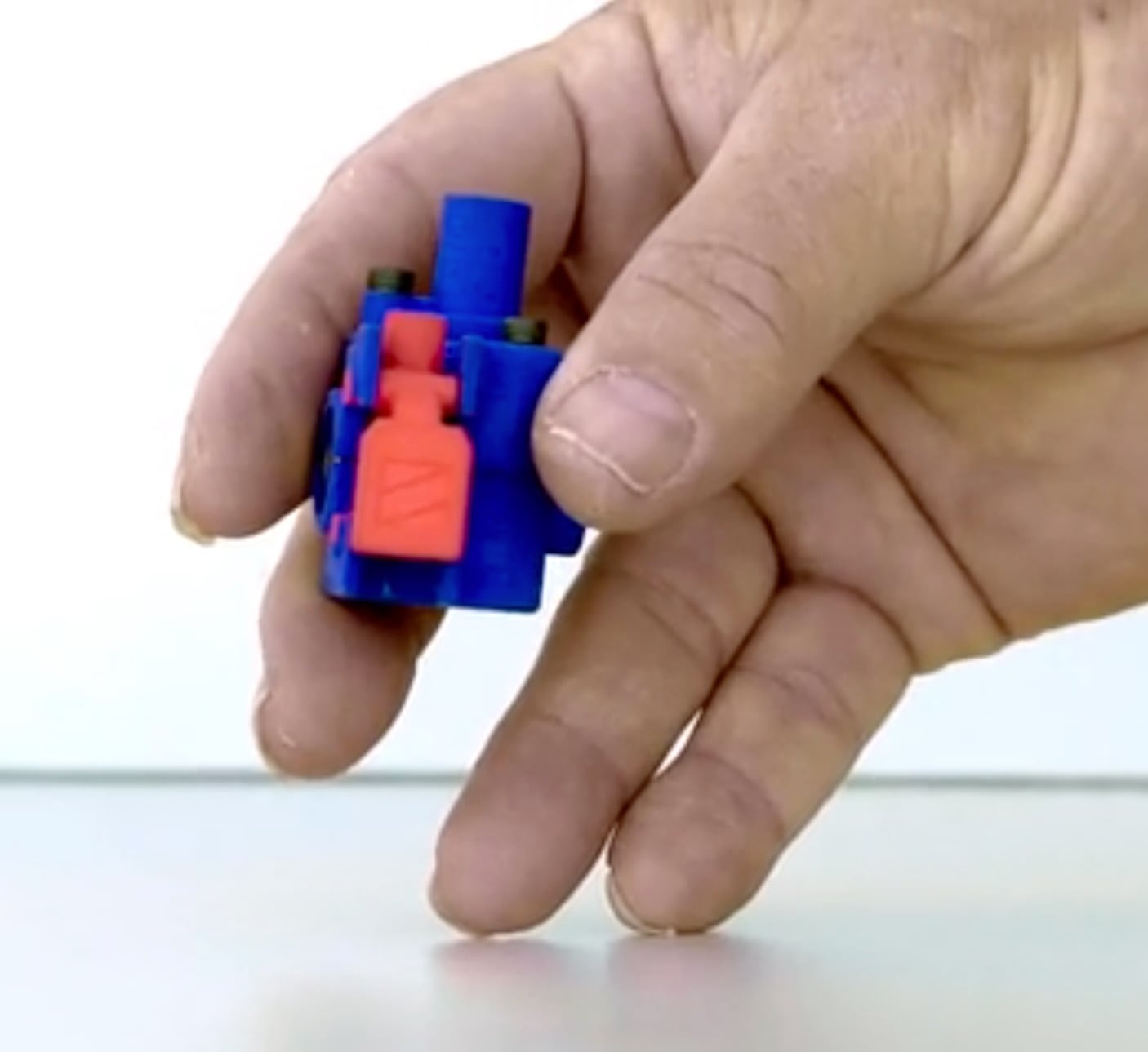

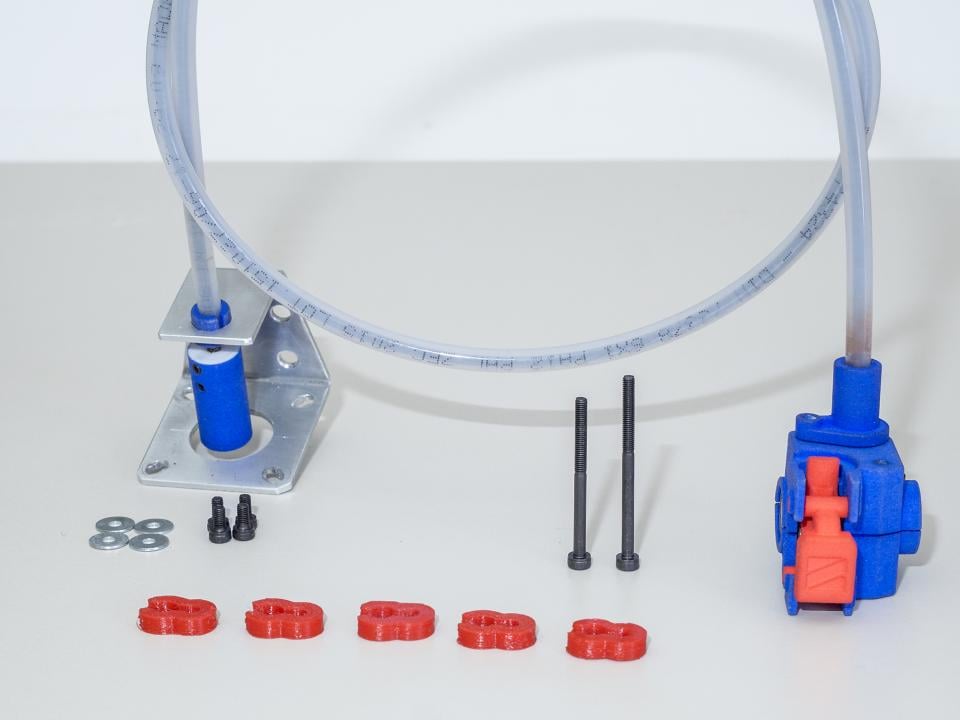

There’s another really useful feature on this extruder: filament insertion is simplified by the ability to “open up” the extruder and drop the filament directly into the hot end. This should make filament installation much easier, though not as much as completely automated designs seen in some machines.

The Nimble design is also reversible! You can flip it over and re-attach some components to change it from left to right, which might be useful if you are installing two of them on one machine.

Finally, another strength of the Nimble is its strength! This little unit has been measured pulling up to 7kg, which is more that sufficient for 3D printing.

There are a couple of reservations about this design, however. First, it’s mostly plastic, meaning it likely cannot handle higher temperatures and thus certain materials may be not compatible with this design.

Another issue that is always present on such campaigns might be reliability. Since this system hasn’t been field tested by hundreds of customers, we don’t yet know how well it works. That’s a risk – that may not come to pass, but a risk nevertheless.

Another risk in play is that once again, we have a small startup company seeking funding. In some cases, such startups fail to deliver the goods. Here Zesty is hoping to raise funds to develop an injection molding process to manufacture the Nimble. But we won’t know if they succeed until much later.

Regardless of the above, the Nimble seems to be an interesting extrusion option, and it’s not priced high either: currently you can secure one for only €77 (USD$84), which includes all the necessary hardware for installation.

Finally, this extruder is said to be part of a future 3D printer design. I’m quite interested to see what the remainder of the machine looks like based on the innovations seen in this extruder.

Via Kickstarter and Zesty