APWorks has released a design for a fabulous 3D printed electric motorcycle called the “Light Rider”. But I think there’s a lot more to this project.

But first, the Light Rider.

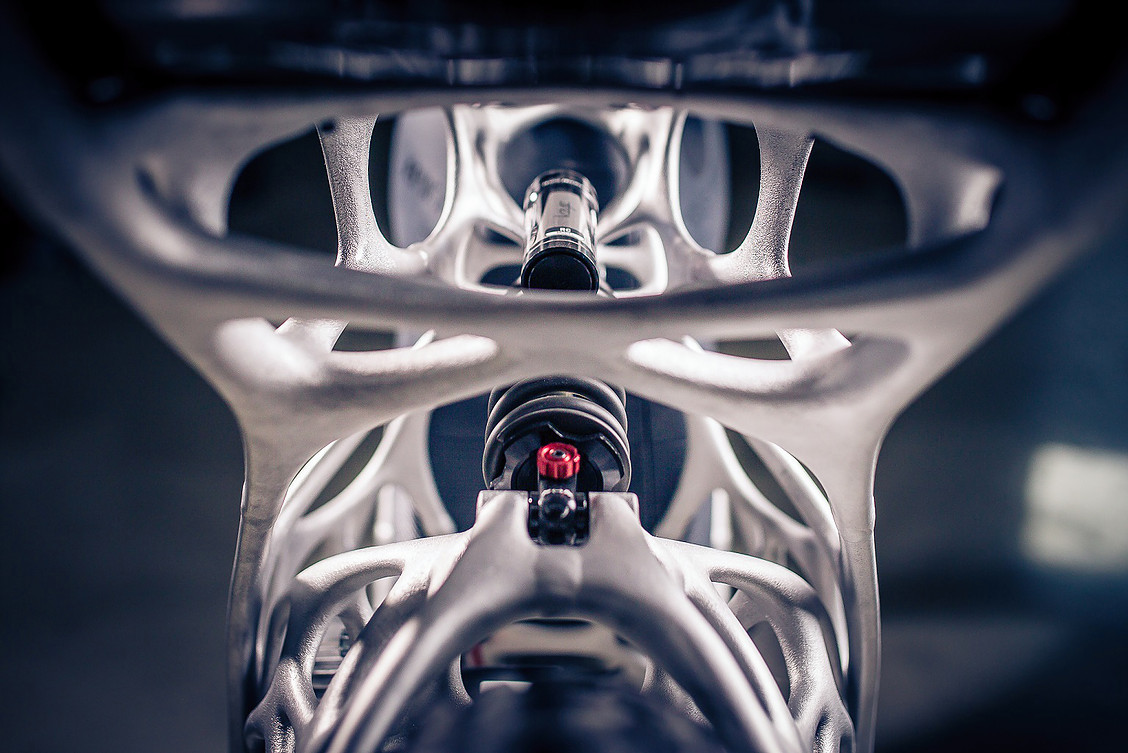

The say it’s the “world’s first 3D printed prototype for an electric motorcycle”, which as far as I know, is true. While the bike includes some common parts that you’d find on any motorcycle, the unique frame was definitely 3D printed – in metal. In fact, APSWorks used their proprietary “scalmalloy”, “As ductile as titanium, as light as aluminium” for the frame.

It’s actually a type of aluminum powder that’s corrosion resistant with very low weight, but not quite as strong as the higher weight titanium metal. The entire bike weighs only 35kg with all assembly completed.

Of course, the bike is also electric powered, in keeping with their futuristic theme. It has a top speed of 80kph, and able to hit 45kph in only three seconds! However, the battery lasts only 60km, and then can be swapped out for a recharge.

Why do this prototype? APWorks’ Niels Grafen explains:

We have used our know how of optimization and manufacturing, to create means of transportation, that match our expectations. Exceptionally strong, impressively lightweight and of the highest quality.

And indeed it is. The frame is a weird generative structure that looks random, but in fact is carefully designed to handle the stresses of the motorcycle’s expected usage.

This is a very interesting project because of who’s doing it: APWorks. If you don’t know, APWorks is a subsidiary of Airbus, the noted aircraft manufacturer.

Why would Airbus work on a ground vehicle? I think it’s because they could be doing a couple of things.

First, they may want to demonstrate their capability in things 3D metal to the world. APWorks does work for not only Airbus, but can do so for other industries, too.

Second, experimentation in new forms of metal 3D printing through other vertical industries may provide APWorks an opportunity to gain knowledge that could subsequently be applied to aircraft manufacturing.

I’m beginning to wonder what the next generation of aircraft may look like, under the skin.

Via Light Rider