I’m reading an interesting piece by Gal Raz on Medium about the file types required by 3D print service bureaus.

3D printing service bureaus originally arose from the high cost of the equipment involved, combined with (initially) low usage per customer. It made sense to “share” the expense of the equipment among many.

What facilitated these services was the classic STL file format, which enabled a customer to electronically transmit the design to the bureau for printing.

But, there’s issues with the STL format, often requiring delicate repair systems to fix holes, flip triangles and other details of fragile STL files. Nevertheless, the 3D printing service bureau industry overcame them and today there are countless service bureaus counting on this STL paradigm.

But as Raz points out in his post, there is often more to the story than just the STL.

Even if the STL is “correct”, the design itself may still be inappropriate for 3D printing – or 3D printing using a particular process.

Each 3D printing process has constraints that may or may not affect the design. For example, there may be a minimum wall thickness.

Normally, such problems require back-and-forth interaction between service bureau and client, ultimately resulting in a “correct” STL file for 3D printing.

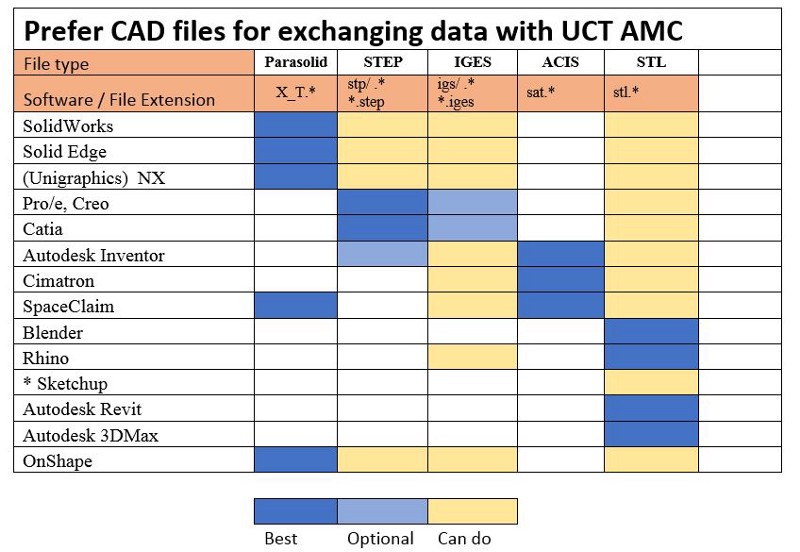

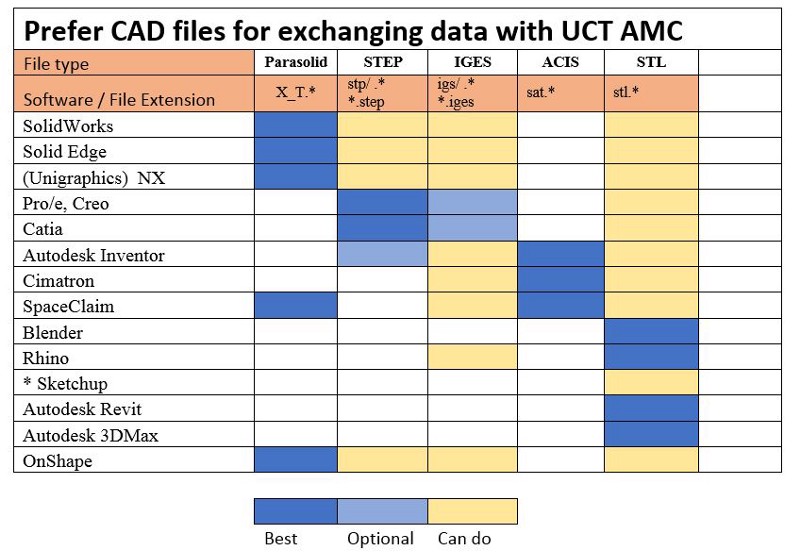

But there is another way, as proposed by Raz: supply not only the STL file, but also the original CAD design file. In this way, the service bureau can (more quickly) fix the design to match the constraints of the machine. Sure, there will be some customer interaction required, but it will be greatly reduced.

This makes the process more efficient. And there’s another benefit too: should the service bureau provide additional services beyond 3D printing, the CAD file may be significant value there, too, as it could be used to assist in various ways, such as finishing, painting, etc.

But there is a challenge that comes with this advantage: security. Some companies may not wish their precious 3D CAD original files to be transmitted elsewhere where they might face exposure and loss.

That will be a challenge for future 3D print service bureaus: a guarantee of security.

Via Medium