Today Stratasys announced perhaps the most important 3D printer in the company’s history: the J750.

Where to start? The J750 is the latest and most powerful iteration in the PolyJet Connex series from Stratasys, although it’s not officially a “Connex”.

Let’s just put it out there: This is a real, live 3D printer that can print not only in virtually any color – but ALSO in multiple materials!

There is no other machine that can do this.

There are a few machines that can do SOME of the functions found in the J750, but none can do all of them at the same time as this incredible machine can. You can print hundreds of digitally generated materials, both hard and flexible, you can print transparent or tinted material, and you can print in virtually any RGB color – with complex textures. And you can do this all that the same time in the same printed model.

How does the J750 manage to do all this? It’s useful to look back at this machine’s PolyJet heritage.

Longtime readers may recall the sequence of events:

- Objet (later acquired by Stratasys) develops PolyJet, a means of fine jetting of photocurable resin to produce high-resolution prints.

- Objet develops “Connex”, in which two PolyJet heads are able to mix different resins together on the fly

- Stratasys (after acquiring Objet) introduces the Connex3, a machine with three PolyJet heads, capable of printing limited “spot color” and somewhat limited ability to use different materials

Today the J750 takes PolyJet technology to the limit by including not four, not five but SIX PolyJet heads.

This means the machine can be loaded not only with a full slate of colored resins, but it can also include resins with different properties, too. All are available for printing in any job. Imagine a hypothetical six material printer configuration:

- Red

- Green

- Blue

- Flexible

- Transparent

- White

What could you print with combinations of those? Quite a lot, I think. And that’s with those six; there are plenty more possible materials you can use in the J750’s six material channels.

Interesting note: I seem to have predicted this development, two years ago when I speculated on a hypothetical “Connex7” machine with seven PolyJet heads. I got it wrong: there are only six. At the time, Stratasys had just announced the Connex3, and it seemed logical that the next step would be to add even more PolyJet heads. This seems to be what happened – and in fact, I learned that the J750 project actually commenced right after the Connex3 announcement, at the same time as my speculation.

Physically, the J750 strongly resembles the Objet500: it’s a large, table-sized unit with an outboard materials box for holding active resin cartridges. Specifications are similar to the Connex3 as well: the J750’s build volume is a very generous 490 x 390 x 200 mm.

Resolution is improved on the J750: the new print heads can deposit 14 micron-sized droplets, whereas prior models were 16 micron.

The machine is said to print up to twice as fast as the Connex3, but there’s a bit of a story to that I’ll explain in a post on the deeper technical details. For now let’s take a look at what the J750 can do.

This is a print of a shoe model. While I’m sure you’ve seen this sort of thing before, this one is very different. For one, the colors are extremely vibrant. For another, the sole is appropriately grippy and flexible. Even though it is a bit heavier to hold than an actual shoe, it is quite startling to have it in your hands: it actually feels like a shoe!

Here’s a set of smartphone cases printed with the J750. As you can see, the new machine is fully capable of applying very colorful texture maps to the surface of 3D models.

Let’s take a closer look at the texture on this case. Amazing! To be very clear; This is NOT painted or finished in any way; it’s straight out of the machine.

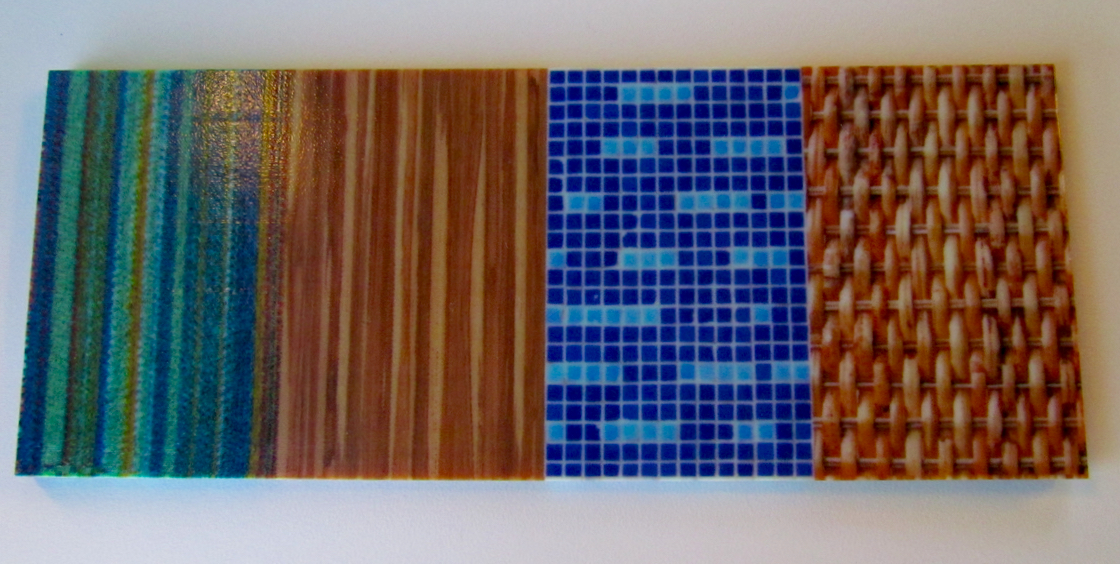

This is a set of sample textures printed on the J750. Notice the very detailed and realistic finishes, particularly on the right.

This is a 3D printed hand, with a difference. The majority of the hand is clear, but inside have been placed a number of different structures representing blood vessels, nerves and joints – and some other stuff I can’t identify as I am not a surgeon. The point here is that the J750 can actually combine different kinds of materials and different colors in the same print.

Similarly, this ia a transparent human head, with the brain exposed on the top. All features within the head are highly detailed and brilliantly colored.

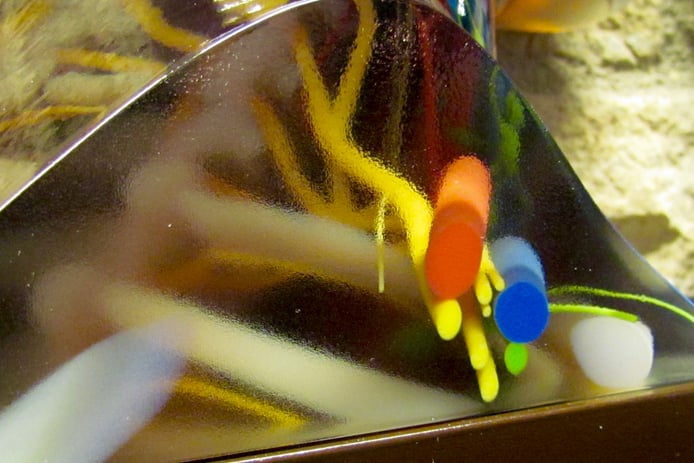

This is a detail shot of the base of the head, where you can peer inside through the deep, transparent material.

Pricing for the J750 was not made available, but I was able to find out that pricing will be at “premium levels”, for obvious reasons. It’s not a surprise to me, given that the J750 is the only machine that can produce prints like this.

I feel the J750 is both an evolutionary and revolutionary step.

It’s evolutionary because physically, the machine simply has three more PolyJet heads and some other improvements. It’s not a completely new machine and Connex users would find it very familiar.

However, the J750 is also revolutionary in that it can print so many more types of objects, far, far greater than any other 3D printer in existence. The evolutionary hardware changes have resulted in dramatic increases in capability.

One quote I heard describing this machine was this:

It’s the 3D printer an 8-year old would imagine.

That’s precisely it: a very powerful machine that can 3D print almost anything. That’s revolutionary.

Much more details and analysis to come.

Via Stratasys